Ore blending scheduling method of strip mine unmanned transportation system

A technology of transportation system and scheduling method, which is applied in the field of mining or quarry scheduling, which can solve the problem of not considering the amount of ore, grade, equipment production capacity, space location, unable to integrate into the unmanned transportation scene of open-pit mines, and not enough for open-pit mines Problems such as ore blending scenarios can achieve the effect of improving ore blending efficiency, fast calculation speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0079] (1) Mathematical model of ore blending

[0080] The construction of the mathematical model of ore distribution is explained here.

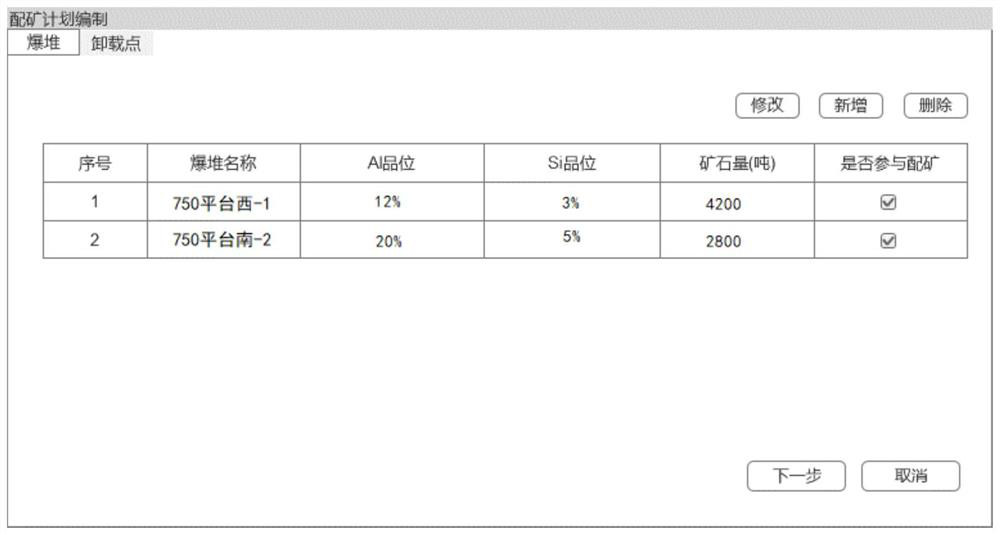

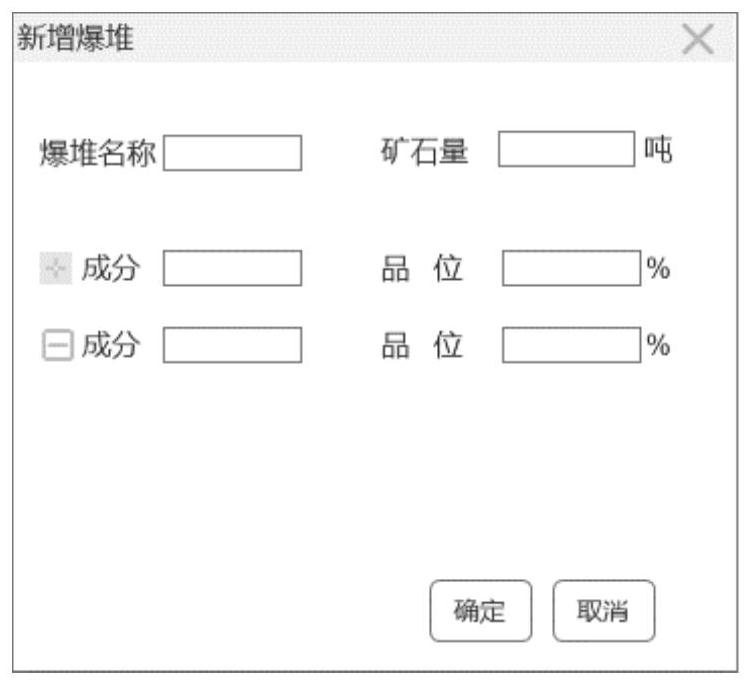

[0081] For example, in the generation of bauxite, assuming that there are 2 explosive piles that can be produced, the composition of the explosive ore is as follows:

[0082]

[0083] Among them, the grade of aluminum (A1) in explosion pile 1=mass of aluminum element / M1, and the grade of silicon (Si)=mass of silicon element / M1.

[0084] Requirements: The Al grade of the ore in the crushing station (discharge port) is controlled at A±5%, and the Si grade is controlled at S±2%. (where A and S are the grade values that need to be controlled, which are known quantities; ±5% and 2% a...

Embodiment 2

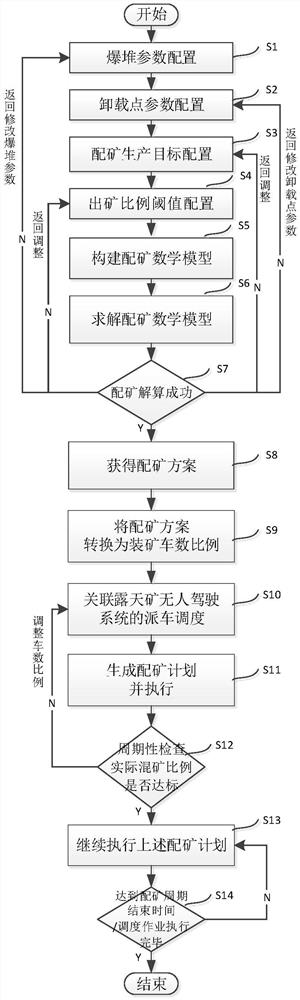

[0157] (1) The technical solution of the present invention has constructed a kind of ore blending scheme of the unmanned transportation system of open-pit mines. First, construct constraint functions respectively according to the explosion pile parameters, unloading point parameters and ore blending grade indicators. According to the aforementioned three constraint functions and the minimum deviation between the mixed ore grade and the target grade at the unloading point to construct a mathematical model of ore blending; then, according to the ore blending production target, the preset ore output ratio threshold and the above three constraint functions to solve the ore blending mathematical model, each The ore output ratio of each explosive stack, and generate an ore allocation plan including the daily average ore output of each explosive stack according to the ore allocation ratio; moreover, convert the ore allocation plan into the ratio of the number of ore loading vehicles, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com