Dynamical correcting method for paste slurry pipeline on-way conveying resistance

A dynamic correction and slurry technology, applied in pipeline systems, gas/liquid distribution and storage, special data processing applications, etc., can solve problems such as unconsidered changes, and achieve the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The method will be further described below according to the implementation situation of the fine-grained tailings concentration, cementation and solidification dry stacking site of a certain iron and steel company.

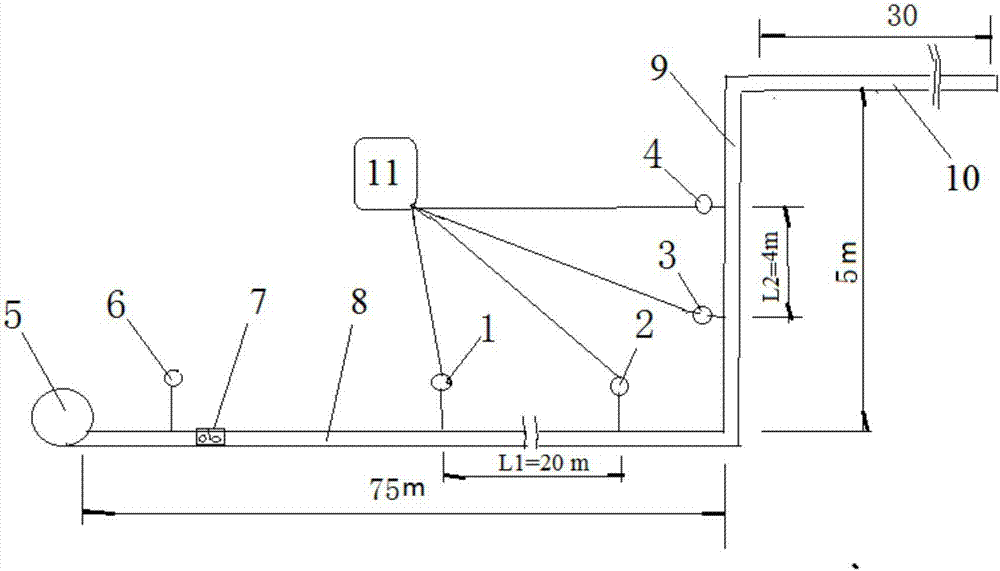

[0044] On-site situation: such as figure 1 As shown, the slurry pipeline conveying system has three sections in total, and the two sections of the horizontal pipe include the first horizontal pipe 8, the second horizontal pipe 10 and a section of vertical pipe 9, and the inner diameter of the conveying pipe is 65mm. Wherein the vertical pipe 9 is perpendicular to the ground (ie β=90°). Since the auxiliary connectors such as valves and elbows in the pipeline will generate additional resistance to the slurry delivery pump 5, it is necessary to convert its length. Conversion factor, length L of the first horizontal pipe section 8 after conversion of the on-site pipeline 水平1 =75m, length L of the second horizontal pipe section 9 水平2 =30m, length L of vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com