Wear-resistant corrosion- resistant composite steel pipe and preparation method thereof

A composite steel pipe, corrosion-resistant technology, applied in the field of wear-resistant materials, can solve the problems of short service life of composite steel pipe, thin thickness of wear-resistant and corrosion-resistant layer, etc., achieve good economic and social benefits, good wear-resistant and corrosion-resistant performance, excellent The effect of wear and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

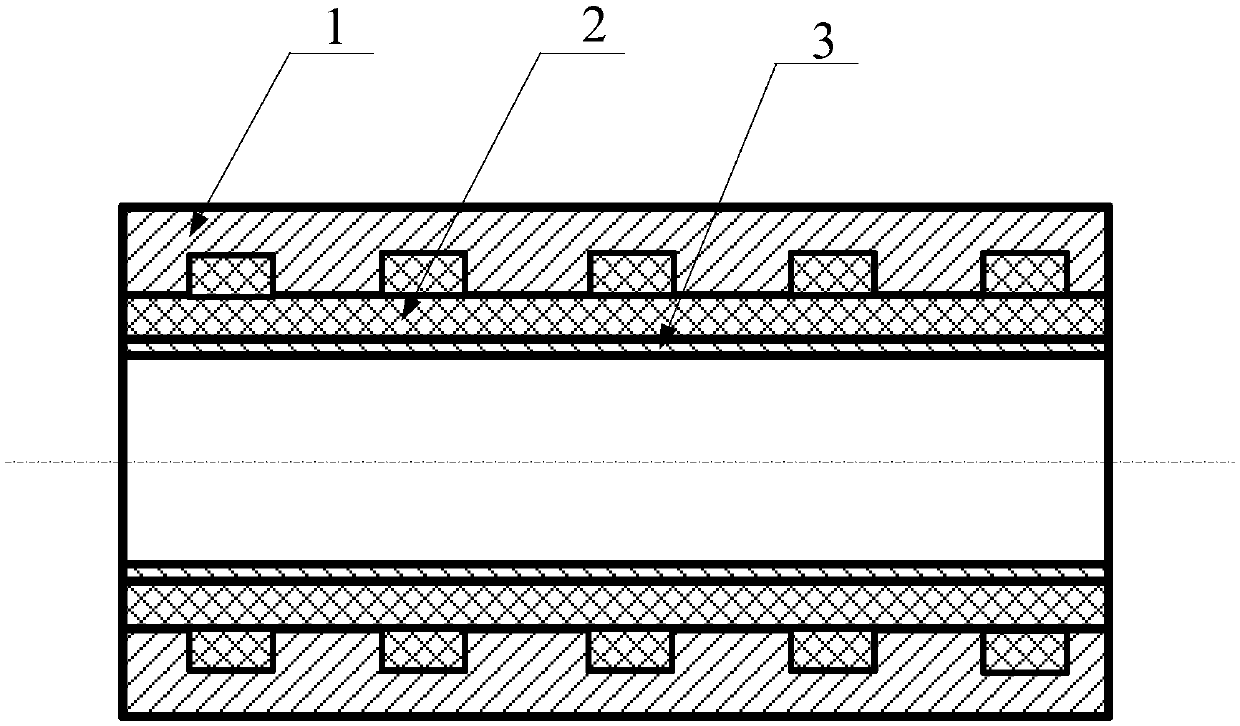

[0037] A method for preparing a wear-resistant and corrosion-resistant composite steel pipe of the present invention comprises firstly compounding wear-resistant and corrosion-resistant high-chromium cast iron on the inner surface of the steel pipe, and then compounding a wear-resistant and corrosion-resistant coating on the surface of the high-chromium cast iron, specifically implemented according to the following steps:

[0038] Step 1. Process the inner surface of the seamless steel pipe with an inner diameter of 200-600 mm and a wall thickness of 15-65 mm along the circumferential direction to form grooves with a width of 8-12 mm and a depth of 3-5 mm. Coat the inner surface and its grooves with a borax aqueous solution with a thickness of 0.8-1.2mm. The mass percentage of borax and water in the borax aqueous solution is 1:1, and then heat the seamless steel pipe to 680-800°C and keep it warm for 2-3 hours Finally, put it on the horizontal centrifuge, start the centrifuge, ...

Embodiment 1

[0049] A method for preparing a wear-resistant and corrosion-resistant composite steel pipe, specifically implemented according to the following steps:

[0050] ① Firstly process grooves with a width of 8mm and a depth of 3mm on the inner surface of the seamless steel pipe 1 with an inner diameter of Φ200mm, a wall thickness of 15mm, and a length of 3000mm along the circumferential direction. , Coating a borax aqueous solution with a thickness of 0.8-1.0mm, the mass percentage of borax and water in the borax aqueous solution is 1:1, then heat the seamless steel pipe to 680°C, keep it warm for 3 hours, place it on a horizontal centrifuge, and then start centrifuge, and adjust the speed of the centrifuge to 1150rpm, and then pour the high-chromium cast iron molten iron with a temperature of 1487°C into the seamless steel pipe on the horizontal centrifuge. The chemical composition and mass percentage of the high-chromium cast iron molten iron are 2.54C , 26.95Cr, 0.94B, 1.41Si, 0...

Embodiment 2

[0054] A method for preparing a wear-resistant and corrosion-resistant composite steel pipe, specifically implemented according to the following steps:

[0055] ① Firstly process grooves with a width of 12mm and a depth of 5mm on the inner surface of the seamless steel pipe 1 with an inner diameter of Φ600mm, a wall thickness of 65mm, and a length of 6000mm along the circumferential direction. , Coating a borax aqueous solution with a thickness of 1.0-1.2mm, the mass percentage of borax and water in the borax aqueous solution is 1:1, then heat the seamless steel pipe to 800 ° C, keep it warm for 2 hours, place it on a horizontal centrifuge, and then start centrifuge, and adjust the speed of the centrifuge to 1050rpm, and then pour the high-chromium cast iron molten iron with a temperature of 1453°C into the seamless steel pipe on the horizontal centrifuge. The chemical composition and mass percentage of the high-chromium cast iron molten iron are 2.62C , 28.30Cr, 0.88B, 1.57Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com