Online switching method of high-pressure long-distance slurry pipeline transmission multi-stage pump station

A pipeline transportation, long-distance technology, applied in pipeline systems, pump control, non-variable-capacity pumps, etc., to achieve the effect of reducing the number of shutdowns and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be specifically described below in conjunction with the accompanying drawings.

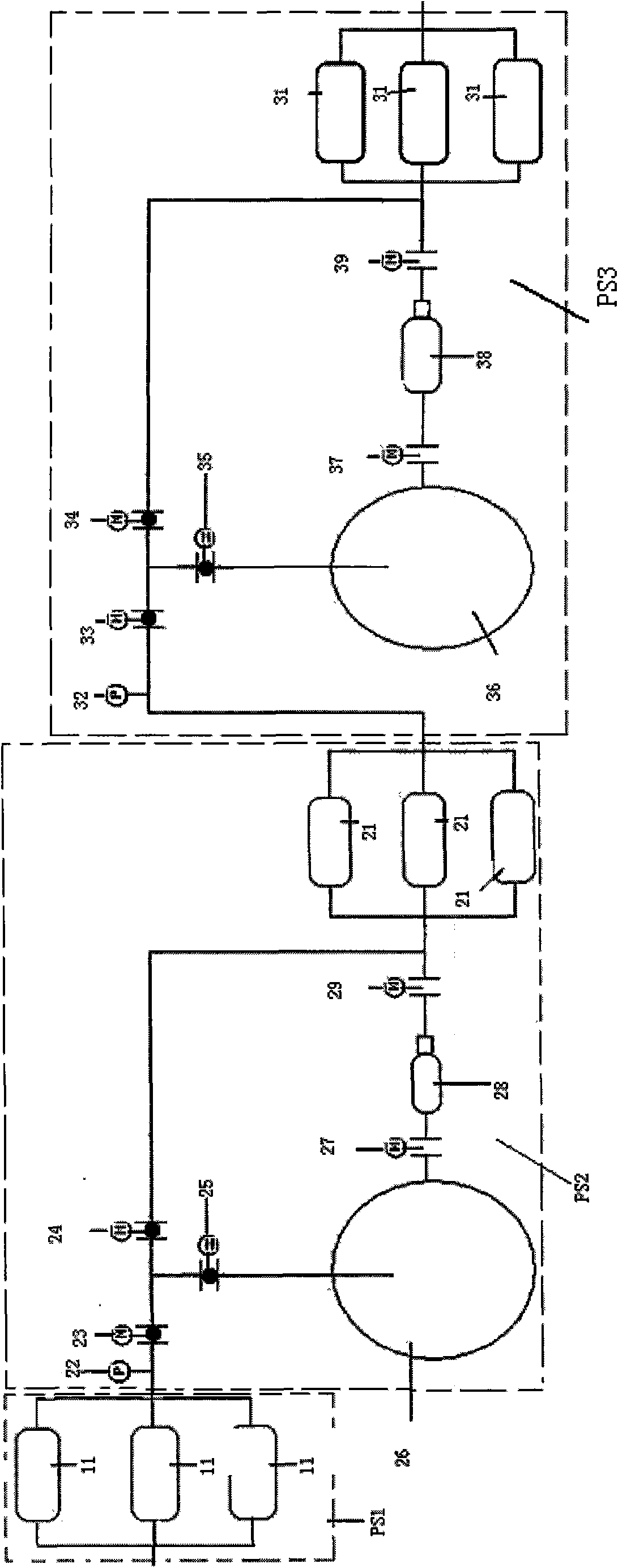

[0035] Such as figure 1 As shown, the output of the three main pumps 11 of the No. 1 pumping station PS1 is connected to the pressure transmitter 22 of the No. 2 pumping station, and its output is divided into two paths through the first electric ball valve 23, and one path is directly connected to the The main pump 22 of the No. 2 pumping station is connected to the stirring tank 8 through the third electric ball valve 25, and the output of the stirring tank 8 is connected to the main pump 22 through the first electric gate valve 27, the feeding pump 28, and the second electric gate valve 29. . The composition structure of No. 3 pumping station is the same as that of No. 2 pumping station.

[0036] (1) Confirmation and precautions before operation:

[0037] 1. Confirm that the multiple delivery valves set in the pipeline can switch normally, the switch is flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com