Sludge drying and incinerating system on basis of incineration of waste grate furnace and treatment method thereof

A technology of sludge drying and treatment method, applied in dewatering/drying/concentrating sludge treatment, combustion method, incinerator, etc., can solve problems such as reducing sludge treatment cost, save landfill land and energy consumption, Cost reduction and thorough treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

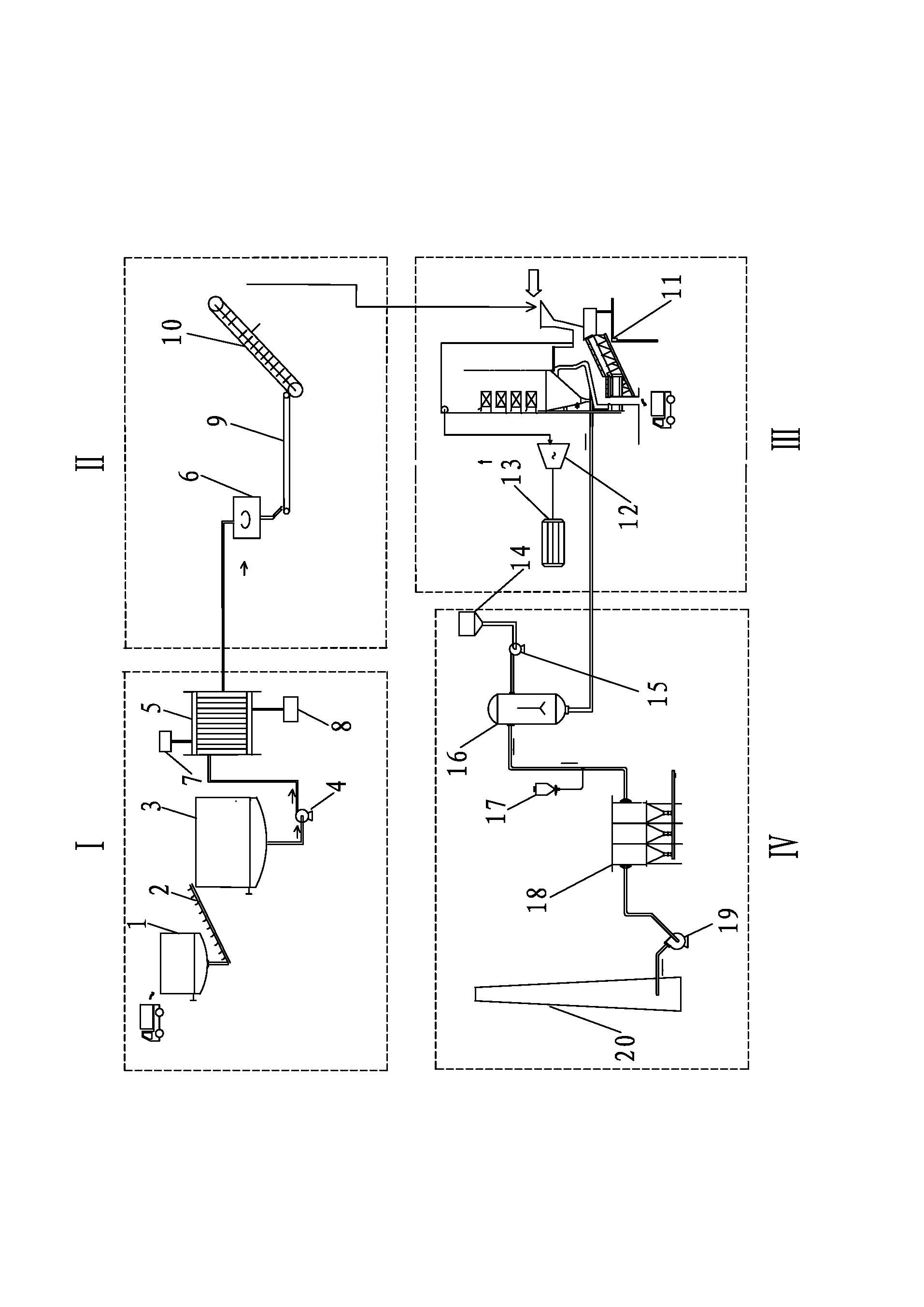

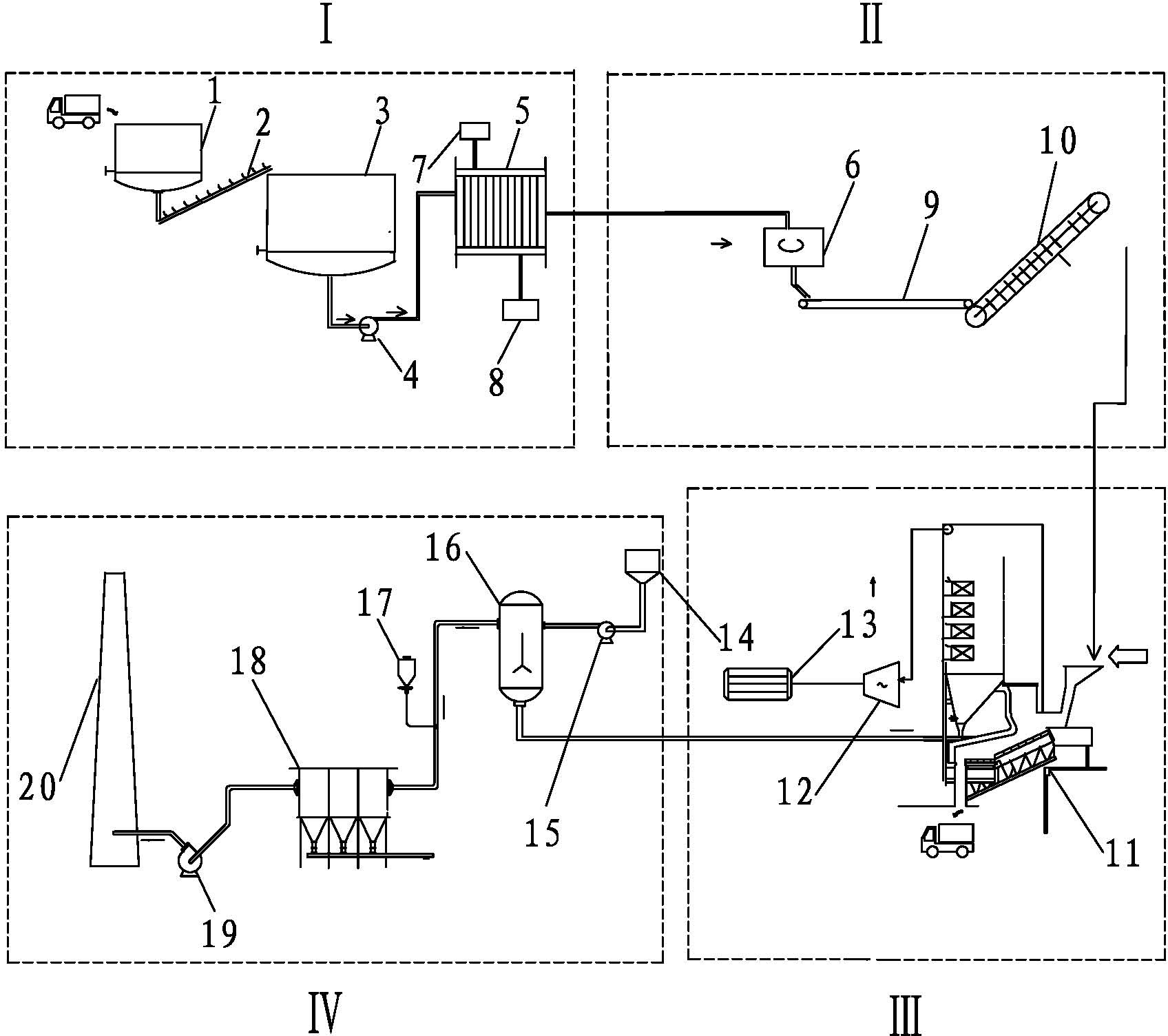

[0039] Cooperate figure 1 As shown, the present invention discloses a sludge drying and incineration system based on garbage grate furnace incineration and its treatment method

[0040] The process equipment used in the method of the present invention can be divided into four processing units: sludge conditioning, filter press and drying unit I, crushing and conveying unit II, incineration power generation unit III, flue gas purification unit IV, such as figure 1 The dashed boxes in the.

[0041] The equipment and process of each unit combined with the process flow figure 1 The instructions are as follows:

[0042] (1) Sludge conditioning filter press drying unit I: The main body of this unit is the sludge conditioning tank 3 and the double diaphragm vacuum filter press 5;

[0043] The sludge with a moisture content of 80% enters the plant and is discharged into the pre-silo 1, and the screw conveyor 2 at the bottom of the pre-silo 1 sends the sludge into the sludge conditioning tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com