Improved development process for light beam homogenization device

A beam and laser beam technology, applied in optics, optical components, instruments, etc., can solve problems such as restricted processing capability, difficulty in ensuring lens curvature and surface accuracy, and difficulty in obtaining uniformity of light spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

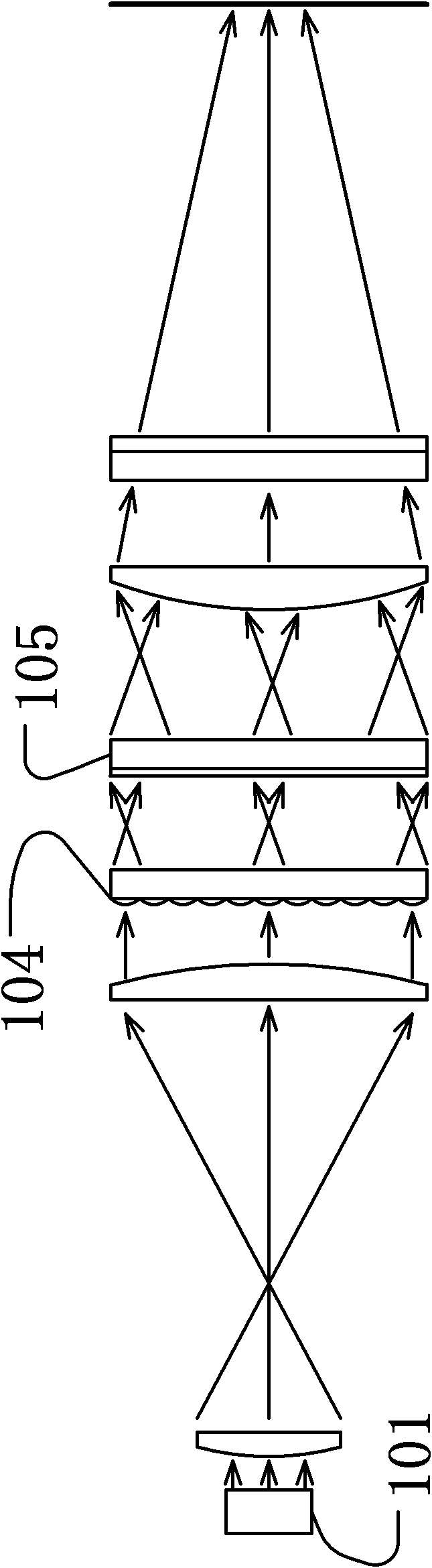

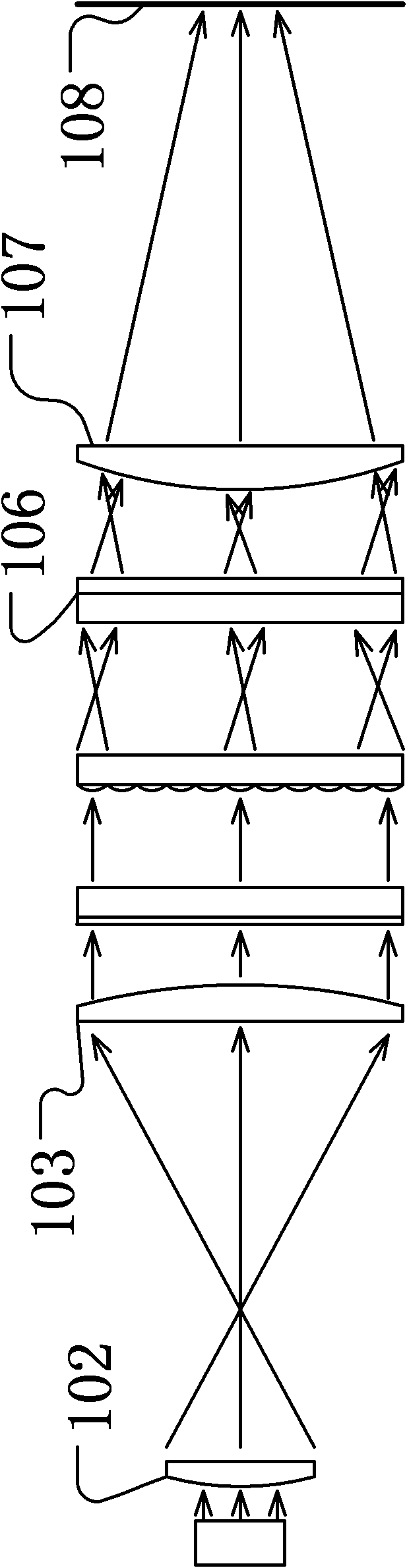

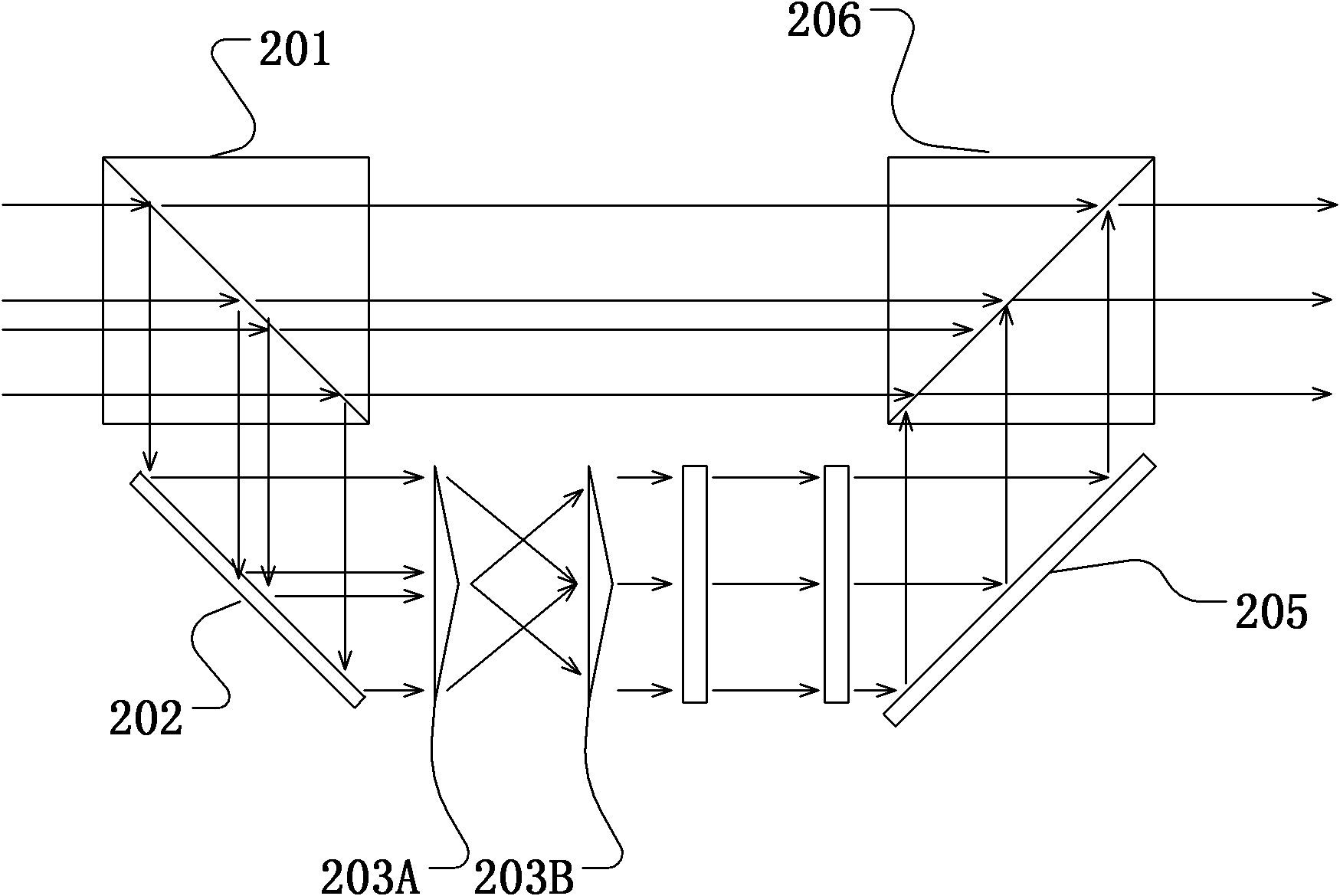

[0025] The purpose of the present invention is to propose an improved optical device for laser beam homogenization, which can be used in laser annealing equipment or other occasions where the beam needs to be homogenized. Adding the pre-homogenization link in the system, as well as the organic combination of different types of homogenization principle schemes, not only greatly reduces the processing difficulty of each optical element in the homogenization system, but also can obtain better homogenization effect.

[0026] The pre-homogenization link device proposed by the present invention is located before the common optical homogenization system, and it performs preliminary homogenization on the light beam and then enters the subsequent optical system to obtain further homogenization. In this way, through multi-level homogenization, a light spot with extremely high uniformity is finally obtained, and at the same time, the requirement for processing capacity is reduced.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com