Mechanical ultrasonic composite homogenization system in storage tank

A mechanical and ultrasonic technology, applied in the direction of mixers, shaking/oscillating/vibrating mixers, mixers with rotating stirring devices, etc., can solve problems such as poor efficiency, poor mixing effect, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

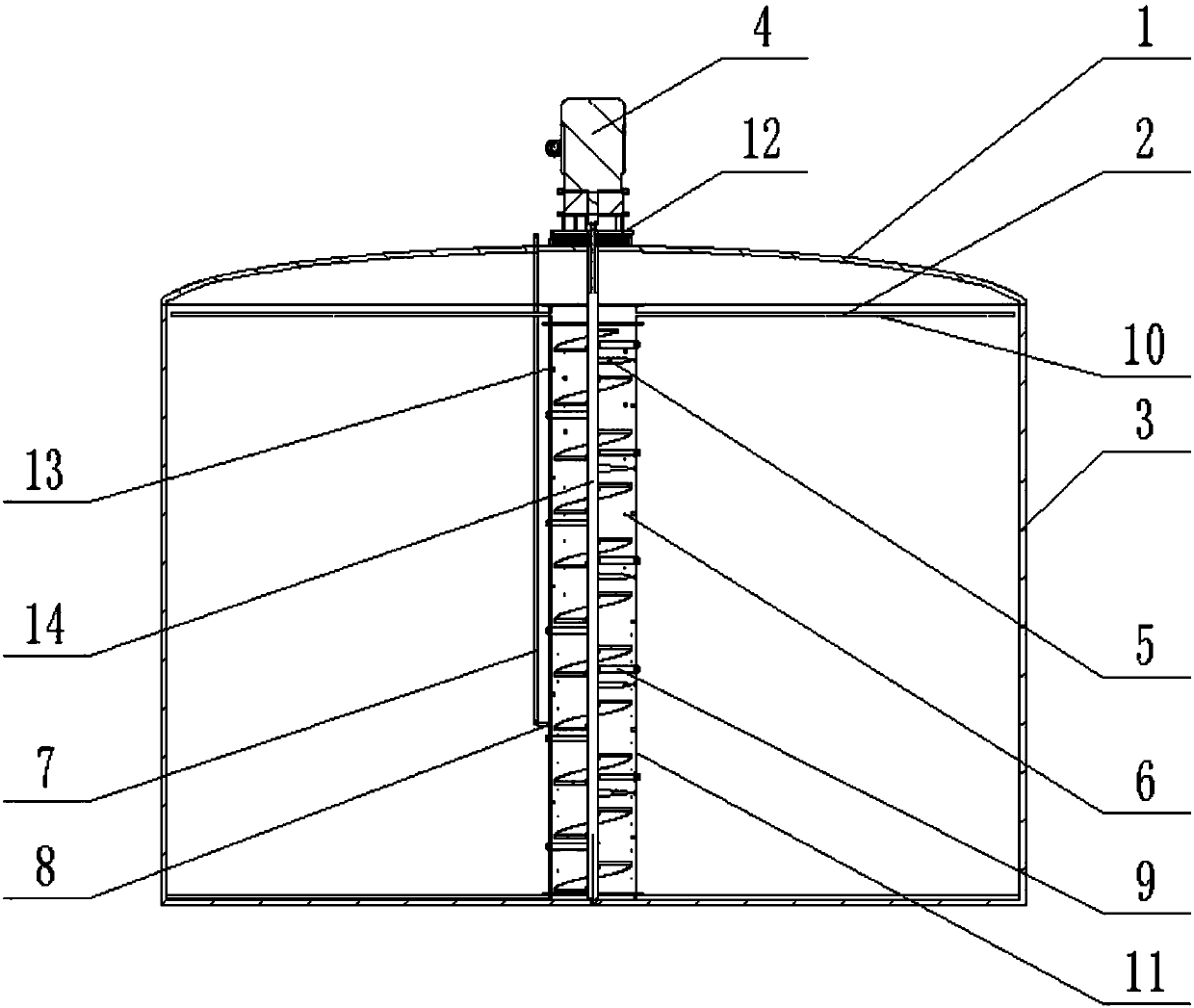

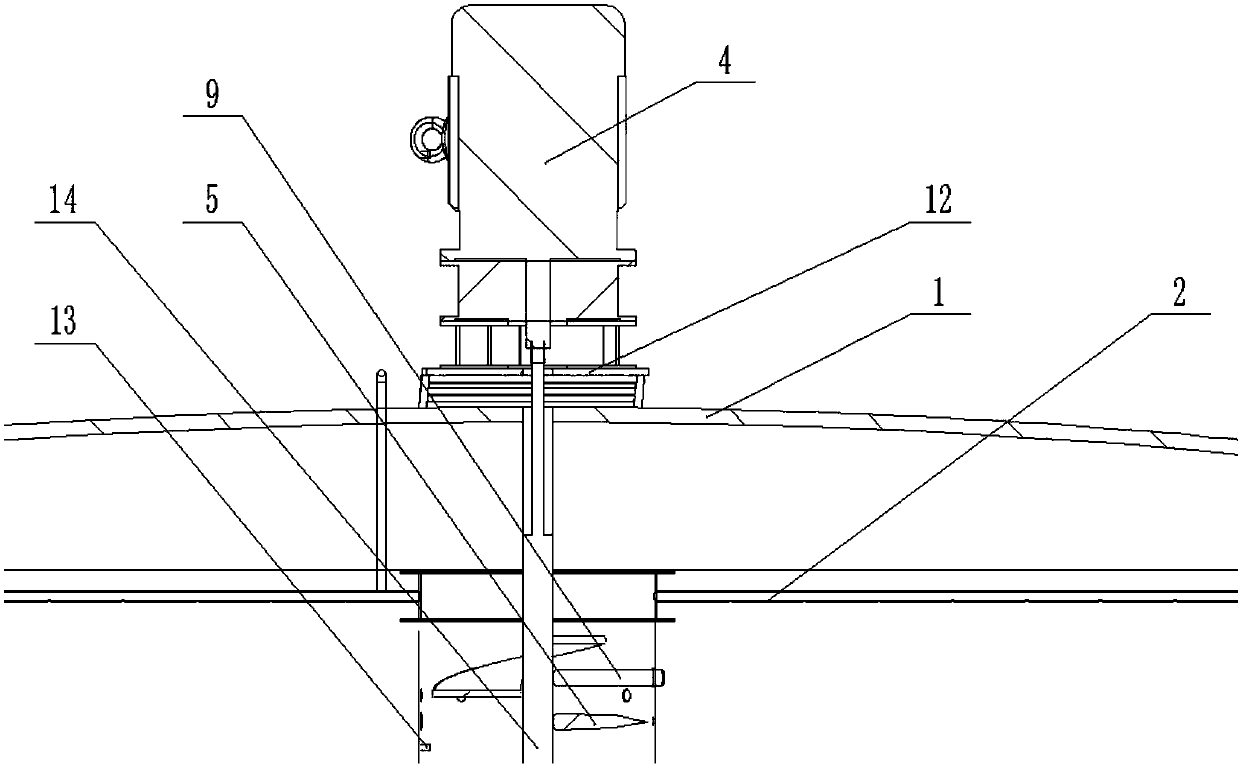

[0022] Combine below Figure 1-5 Describe this embodiment, a mechanical ultrasonic composite homogenization system in a storage tank, including a tank upper cover 1, a tank body 3, a mechanical rotation stirring motor 4, a motor fixing frame 12, a liquid taking tube 7 and a liquid mixing cylinder 11, the The liquid mixing cylinder 11 is provided with an auger helical blade 5, an ultrasonic transducer 9, a rotating central axis 14 and a temperature sensor 13, and a plurality of ultrasonic transducers 9 are evenly and interlacedly arranged on the inner wall of the liquid mixing cylinder 11, and the liquid mixing cylinder 11 A plurality of temperature sensors 13 are arranged inside, and a plurality of temperature sensors 13 are respectively arranged adjacent to a plurality of ultrasonic transducers 9; the side wall of the mixing cylinder 11 is provided with a plurality of liquid inlet holes 6 and a liquid intake port 8, The top of the mixing tube 11 is provided with four drain pi...

specific Embodiment approach 2

[0024] Combine below Figure 1-5 This embodiment will be described, and this embodiment will further describe Embodiment 1. The multiple liquid inlet holes 6 on the side wall of the mixing tube 11 are evenly distributed from top to bottom, and the diameters of the multiple liquid inlet holes 6 decrease sequentially from top to bottom. Small; the reason for this design is that because the pressure at the bottom of the mixing cylinder 11 is strong and the pressure at the top is small, this design can make the liquid intake of each layer of liquid into the mixing cylinder the same.

specific Embodiment approach 3

[0025] Combine below Figure 1-5 This embodiment will be described. This embodiment will further describe Embodiment 1, and the position of the liquid intake port 8 on the outer wall of the liquid mixing cylinder 11 is arbitrary.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com