Coconut milk Qingbuliang and preparation method thereof

A coconut milk clearing, refreshing and cooling technology, applied in the field of refreshing and refreshing, can solve the problems of losing the refreshing and refreshing flavor of coconut milk, unable to transport and sell long-distance, and not having a long shelf life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

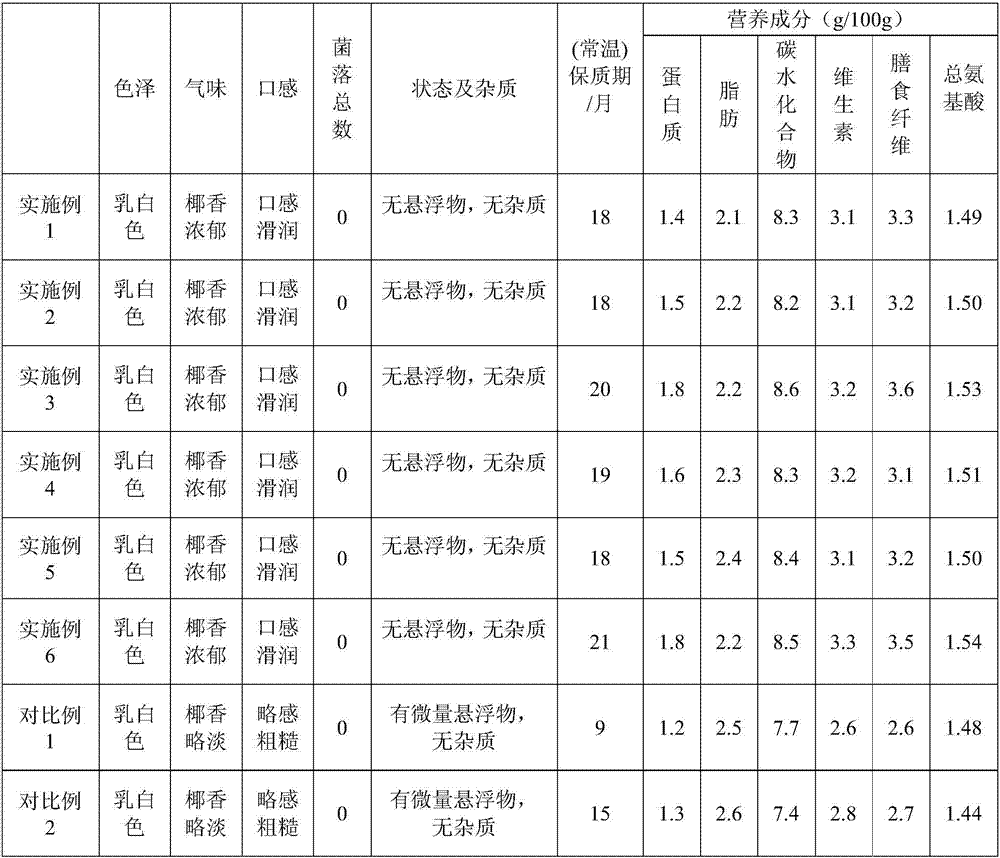

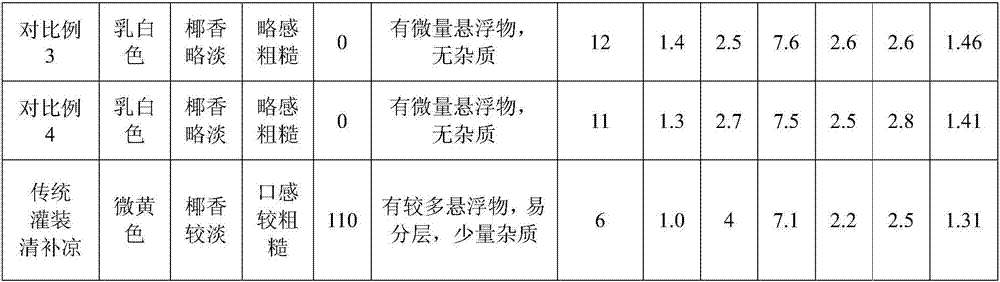

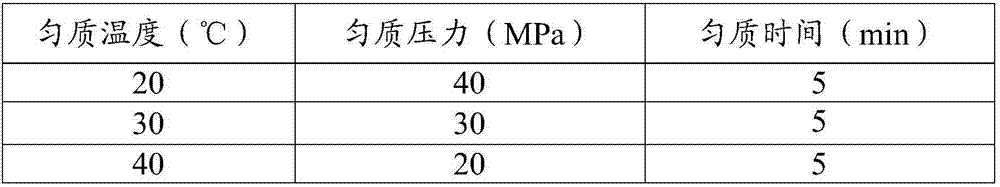

Examples

Embodiment 1

[0027] A kind of coconut milk for refreshing and cooling, comprising the following raw materials in mass percentage: coconut fiber 6%, wheat kernel 0.5%, corn 3%, sago 0.5%, oat 0.5%, red bean 0.5%, honey 5%, emulsification stabilizer 0.1%, surplus is coconut milk; Described emulsification stabilizer comprises sodium caseinate, glyceryl monostearate, sucrose fatty acid ester, sodium carboxymethyl cellulose; Described coconut milk is 1 by weight ratio: 1 coconut meat and purified water.

Embodiment 2

[0029] A kind of coconut milk for refreshing and cooling, comprising the following raw materials in mass percentage: 8% of coconut fiber, 0.8% of wheat kernel, 5% of corn, 0.8% of sago, 1% of oat, 0.8% of red bean, 10% of honey, and emulsification stabilizer 0.2%, surplus is coconut milk; Described emulsification stabilizer comprises sodium caseinate, glyceryl monostearate, sucrose fatty acid ester, sodium carboxymethyl cellulose; Described coconut milk is 1 by weight ratio: 2 coconut meat and purified water.

Embodiment 3

[0031] A kind of coconut milk for refreshing and cooling, comprising the following raw materials in mass percentage: 7% of coconut fiber fruit, 0.7% of wheat kernel, 4% of corn, 0.6% of sago, 0.8% of oat, 0.7% of red bean, 8% of honey, and emulsification stabilizer 0.15%, surplus is coconut milk; Described emulsification stabilizer comprises sodium caseinate, glyceryl monostearate, sucrose fatty acid ester, sodium carboxymethyl cellulose; Described coconut milk is 2 by weight ratio: 3 coconut meat and purified water.

[0032] The preparation method of the coconut milk of the above-mentioned embodiments 1-3 for clearing and nourishing cool comprises the following steps:

[0033] S1. Preparation of coconut milk: select fresh coconut meat, use a coconut meat grater to make it into shredded coconut, add pure water according to the above weight ratio, and carry out low-temperature cold pressing at 30°C, pass through a 1000-mesh sieve, and filter Obtain milky white liquid namely co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com