Cement raw meal homogenizing silo

A technology for cement raw meal and homogenization silo, applied in cement production, clinker production and other directions, can solve the problems of poor silo structure safety, general homogenization effect, complex silo structure, etc. Energy consumption and the effect of reducing the height of the library body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

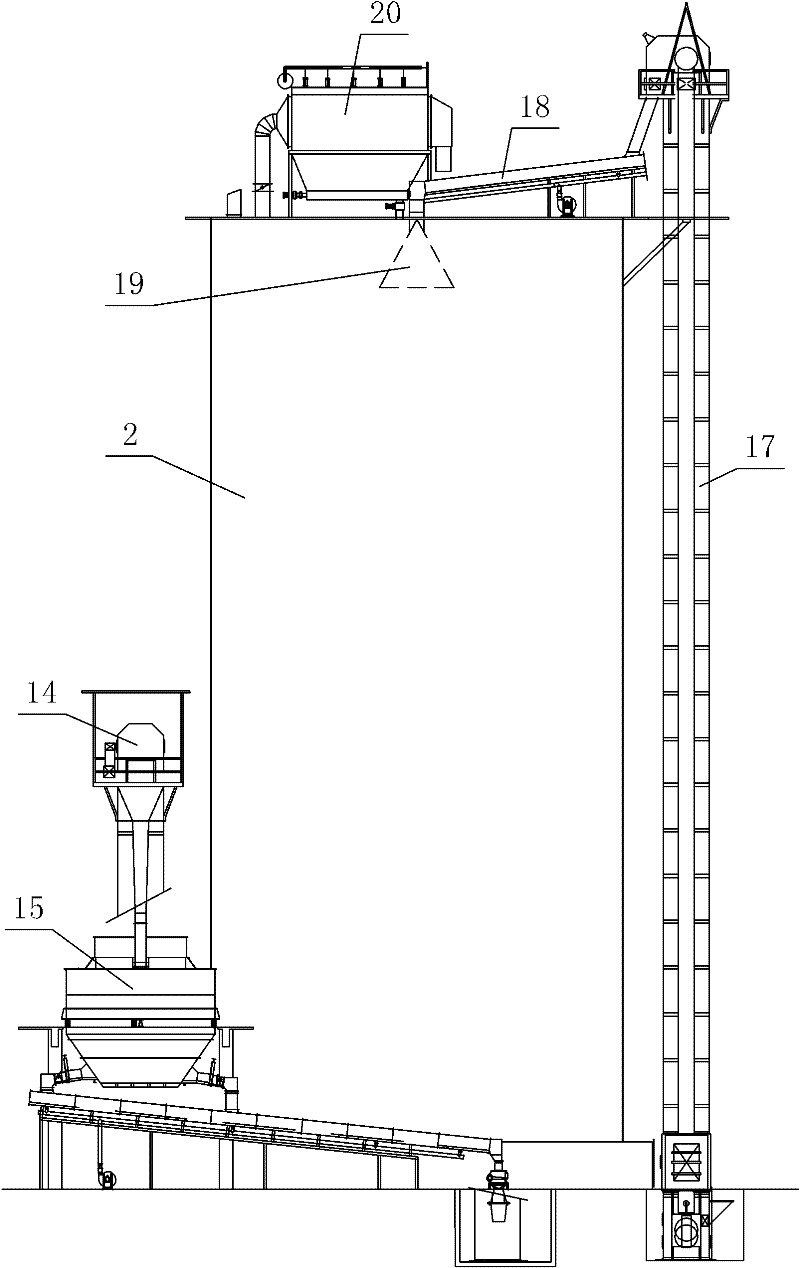

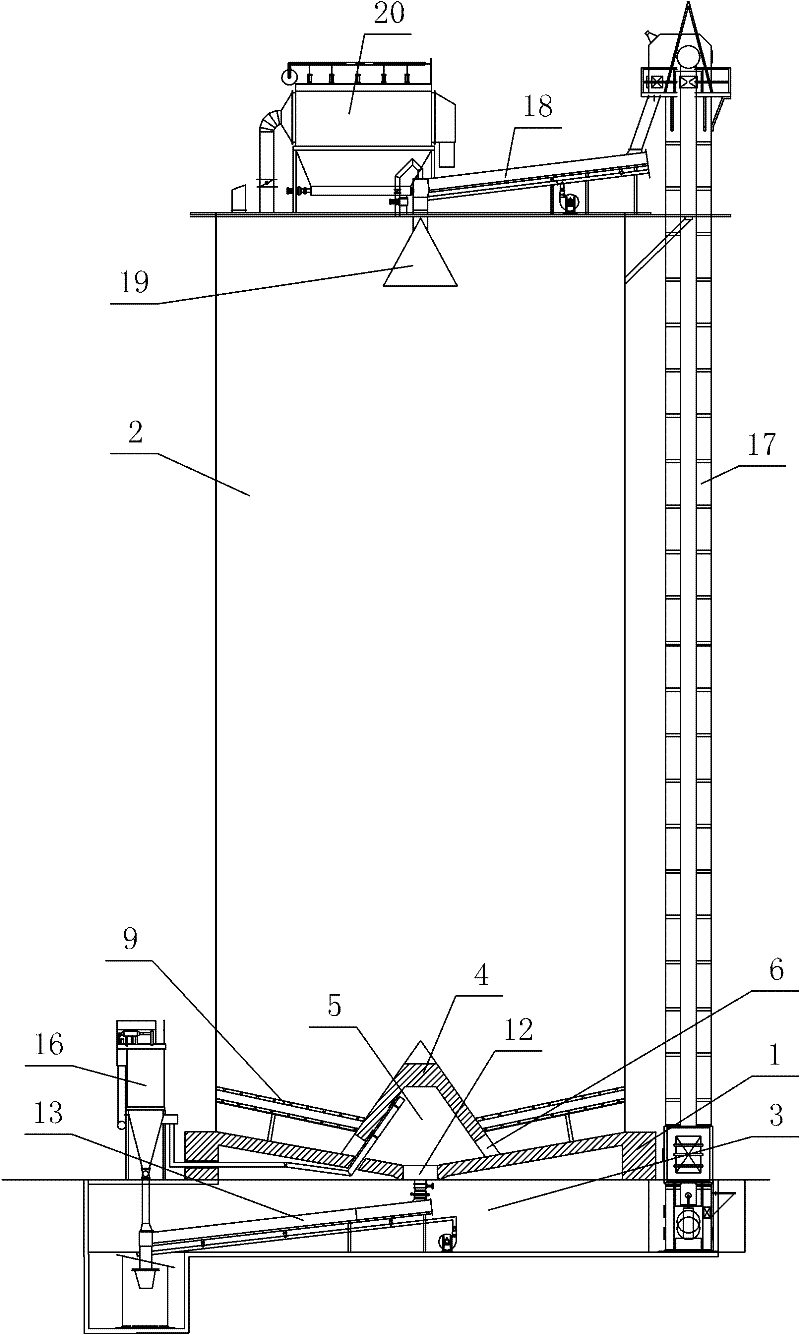

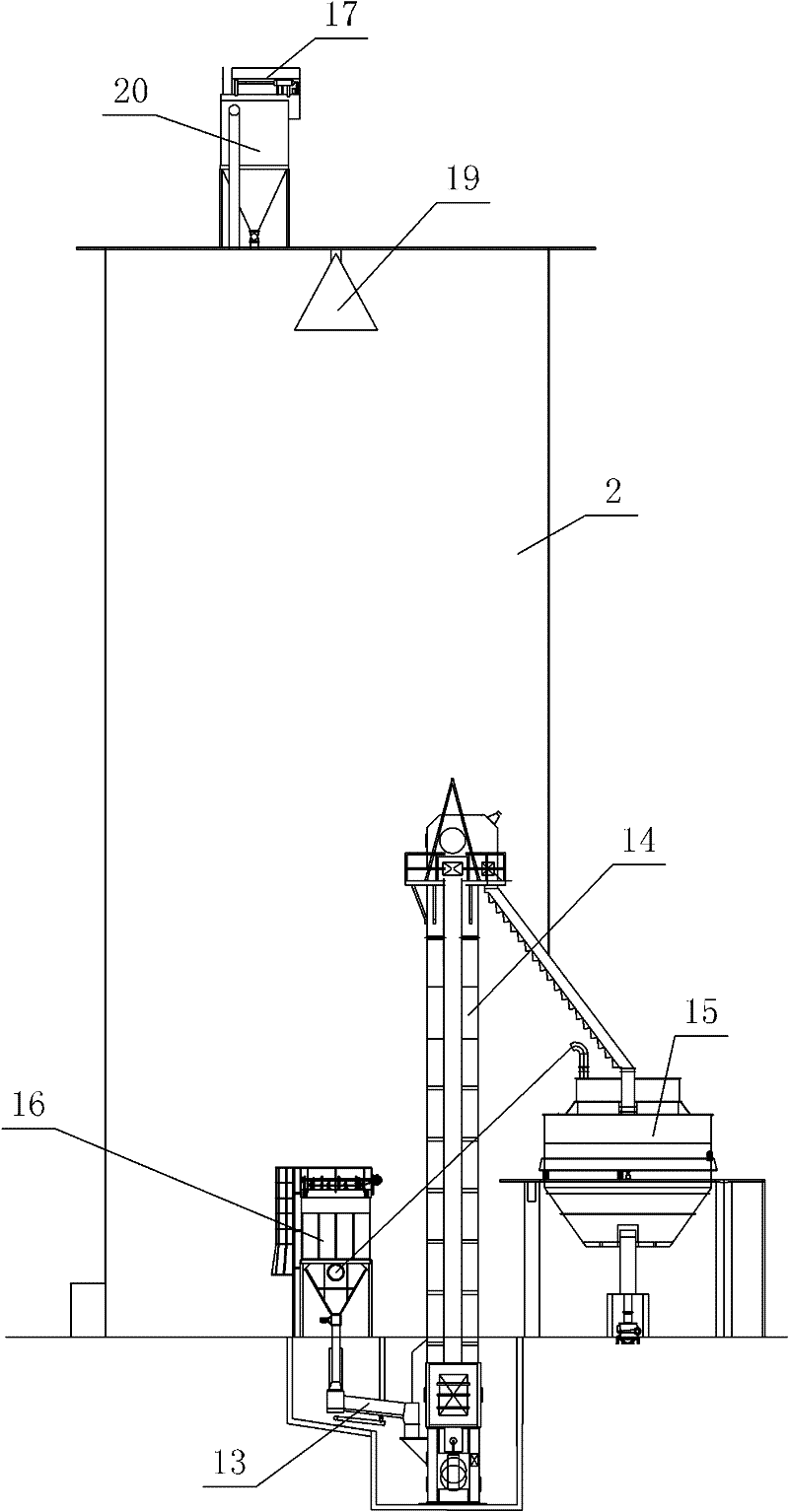

[0013] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0014] like Figure 1~5 As shown, the present invention comprises the base 1 of the underground part and the steel warehouse body 2 of the ground part fixedly connected with the base 1 above the base 1, and a cavity 3 is provided inside the base 1, and the top of the base 1 The surface is an inclined inverted cone slope. A decompression cone 4 is provided at the center of the top of the base 1. A mixing chamber 5 is provided inside the decompression cone 4. At the junction of the bottom of the decompression cone 4 and the top of the base 1 A number of feeding holes 6 are evenly arranged along the circumference, and a collection tank 7 is provided on the inclined surface of the top of the base 1 corresponding to each feeding hole 6, and a collection aerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com