Powdery material homogenizing steel plate silo and use method thereof

A technology for powder material and steel plate storage, which is used in large-capacity bulk material storage, industrial buildings, building types, etc. It can solve the problems of poor material delivery, single performance, low delivery rate, etc. And the effect of high abundance, simple structure and high delivery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

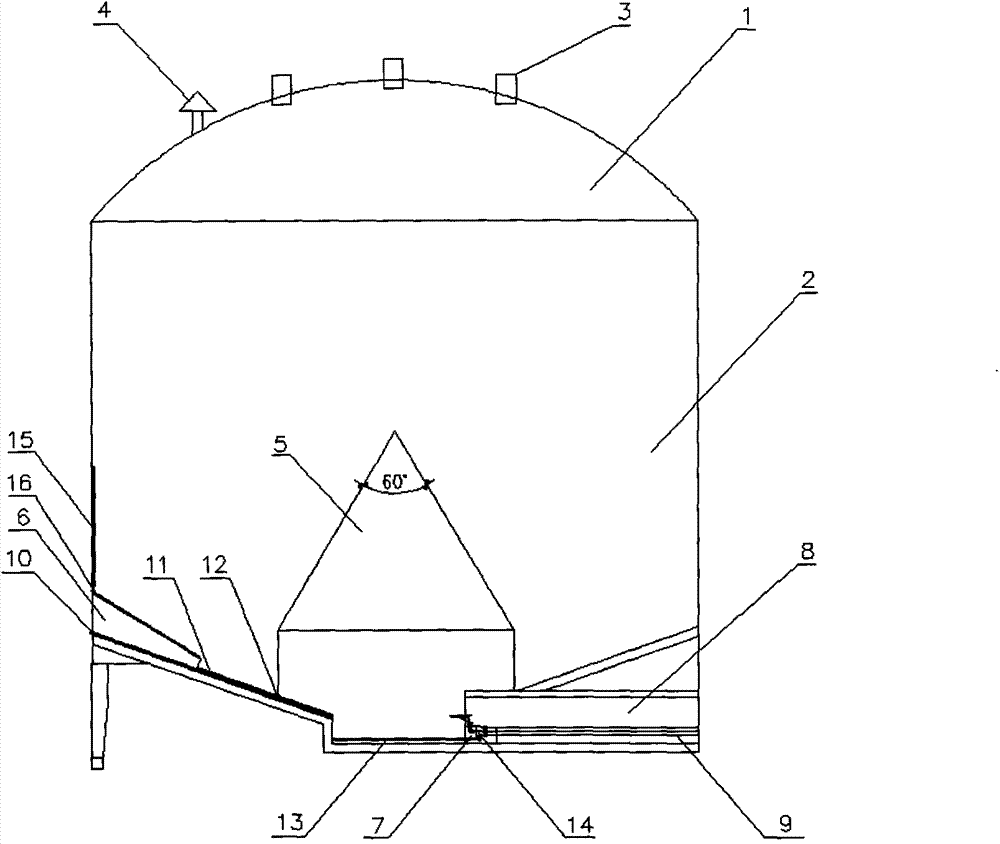

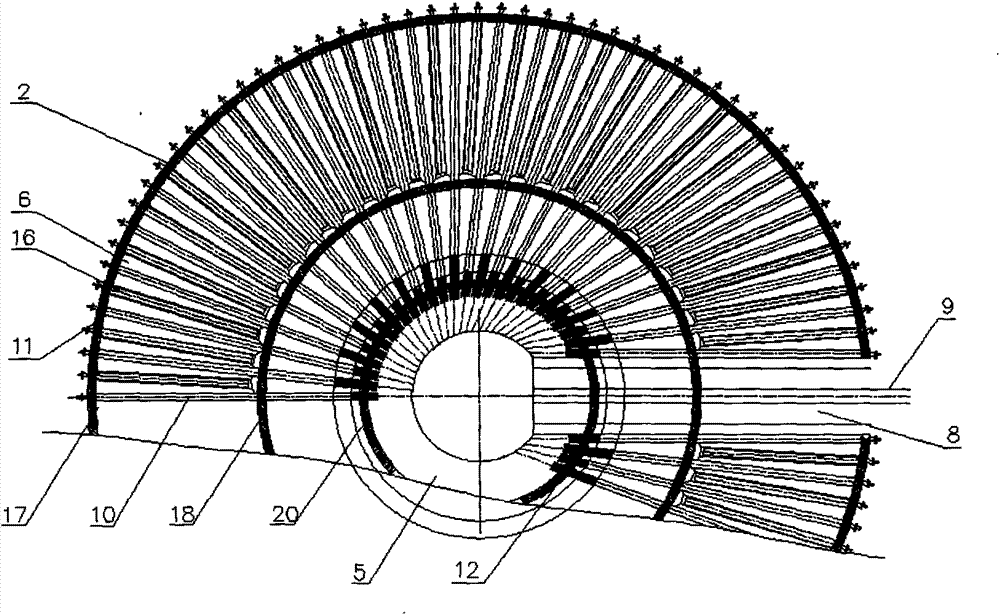

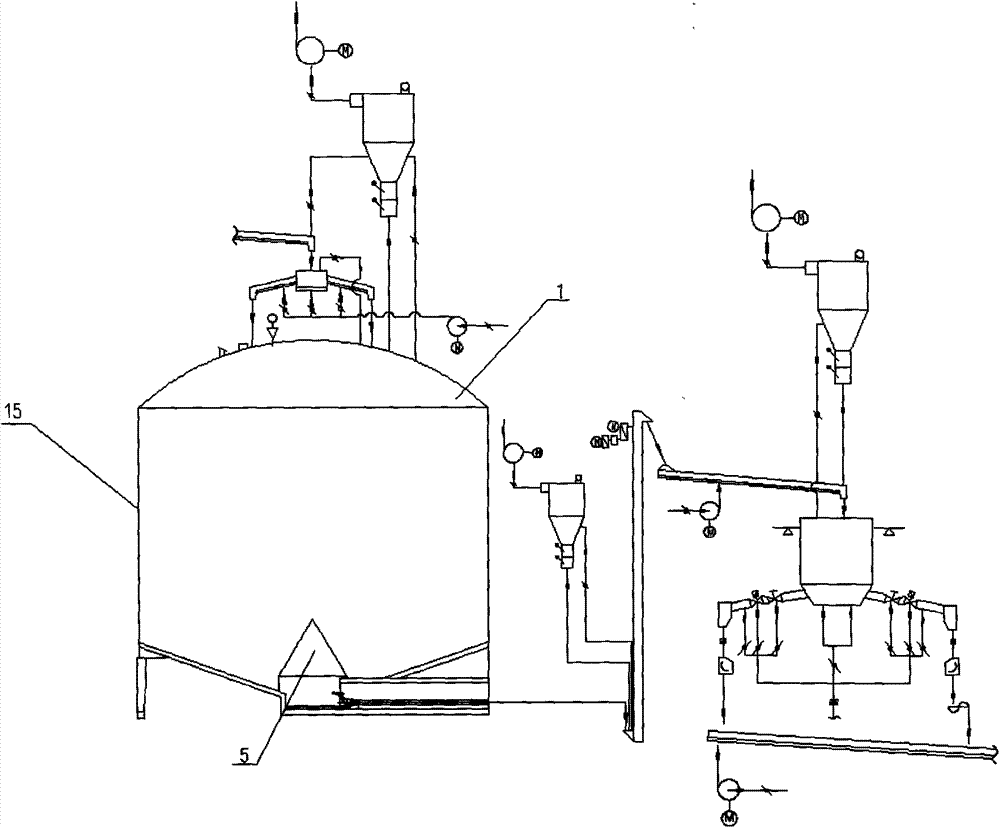

[0035] The present invention will be described below in conjunction with the accompanying drawings. Such as Figure 1-Figure 6 as shown, figure 1 Structural diagram of powder material homogenization steel plate warehouse; figure 2 Layout plan of warehouse floor; image 3 Process flow chart of powder material homogenization steel plate warehouse; Figure 4 Schematic diagram of the structure of the decompression cone; Figure 5 Plane schematic diagram of the guide cone; Figure 6 A schematic diagram of the guide cone.

[0036]The present invention comprises a storage body 2 and a storage top 1, the storage top 1 is arched, the storage top 1 and the storage body 2 are fixedly connected, and the storage top 1 is provided with a safety valve 4 and a plurality of material inlets 3, wherein the storage The center of the bottom of the body 2 is provided with a decompression cone 5, the lower part of the decompression cone 5 is cylindrical, and the cylindrical straight section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com