Method for preparing low-particle size ternary cathode material

A technology of positive electrode material and particle size, which is applied in the field of preparation of low particle size ternary positive electrode materials, can solve problems such as uneven distribution, uneven particle size, unstable electrochemical performance, etc., to achieve improved performance efficiency and strong activity , The preparation method is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

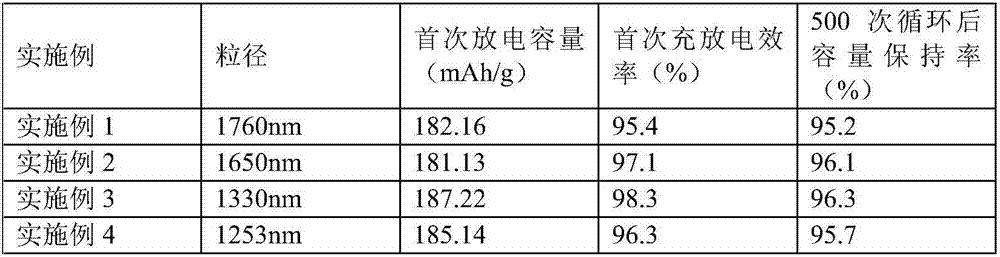

Examples

Embodiment 1

[0024] A preparation method of a low particle size ternary positive electrode material, the steps are as follows:

[0025] Step 1, dissolving lithium acetate, nickel acetate, cobalt acetate and manganese acetate in absolute ethanol, adding polyvinylpyrrolidone to seal and heat for 2 hours to obtain an encapsulated metal ion sol;

[0026] Step 2, the sol solution is added to the reactor and distilled under reduced pressure until a viscous solution is formed;

[0027] Step 3, add acetic acid and ethyl acetate to the viscous liquid, reflux for 10 hours, remove the ethyl acetate layer after cooling, obtain the acetic acid layer, and obtain a mixed acetic acid solution;

[0028] Step 4, adding distilled water to the mixed acetic acid solution, and then distilling off the acetic acid with slight heat to obtain a mixed aqueous solution;

[0029] Step 5, injecting carbon dioxide into the mixed aqueous solution, and circulating the aeration reaction to form sediment until the sediment...

Embodiment 2

[0039] A preparation method of a low particle size ternary positive electrode material, the steps are as follows:

[0040] Step 1, dissolving lithium acetate, nickel acetate, cobalt acetate and manganese acetate in absolute ethanol, adding polyvinylpyrrolidone to seal and heat for reaction for 4 hours, to obtain an encapsulated metal ion sol;

[0041] Step 2, the sol solution is added to the reactor and distilled under reduced pressure until a viscous solution is formed;

[0042] Step 3, add acetic acid and ethyl acetate to the viscous liquid, reflux for 15 hours, remove the ethyl acetate layer after cooling, obtain the acetic acid layer, and obtain a mixed acetic acid solution;

[0043]Step 4, adding distilled water to the mixed acetic acid solution, and then distilling off the acetic acid with slight heat to obtain a mixed aqueous solution;

[0044] Step 5, injecting carbon dioxide into the mixed aqueous solution, and circulating the aeration reaction to form sediment until...

Embodiment 3

[0054] A preparation method of a low particle size ternary positive electrode material, the steps are as follows:

[0055] Step 1, dissolving lithium acetate, nickel acetate, cobalt acetate and manganese acetate in absolute ethanol, adding polyvinylpyrrolidone and sealing and heating for 3 hours to obtain an encapsulated metal ion sol;

[0056] Step 2, the sol solution is added to the reactor and distilled under reduced pressure until a viscous solution is formed;

[0057] Step 3, add acetic acid and ethyl acetate to the viscous liquid, reflux for 13 hours, remove the ethyl acetate layer after cooling, obtain the acetic acid layer, and obtain a mixed acetic acid solution;

[0058] Step 4, adding distilled water to the mixed acetic acid solution, and then distilling off the acetic acid with slight heat to obtain a mixed aqueous solution;

[0059] Step 5, injecting carbon dioxide into the mixed aqueous solution, and circulating the aeration reaction to form sediment until the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com