Method for preparing ethyl alcohol by acetic acid hydrogenation

A technology for hydrogen production and ethanol, which is applied in the field of acetic acid hydrogenation to produce ethanol, can solve the problem of low ethanol selectivity, achieve high ethanol selectivity, high acetic acid conversion rate, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

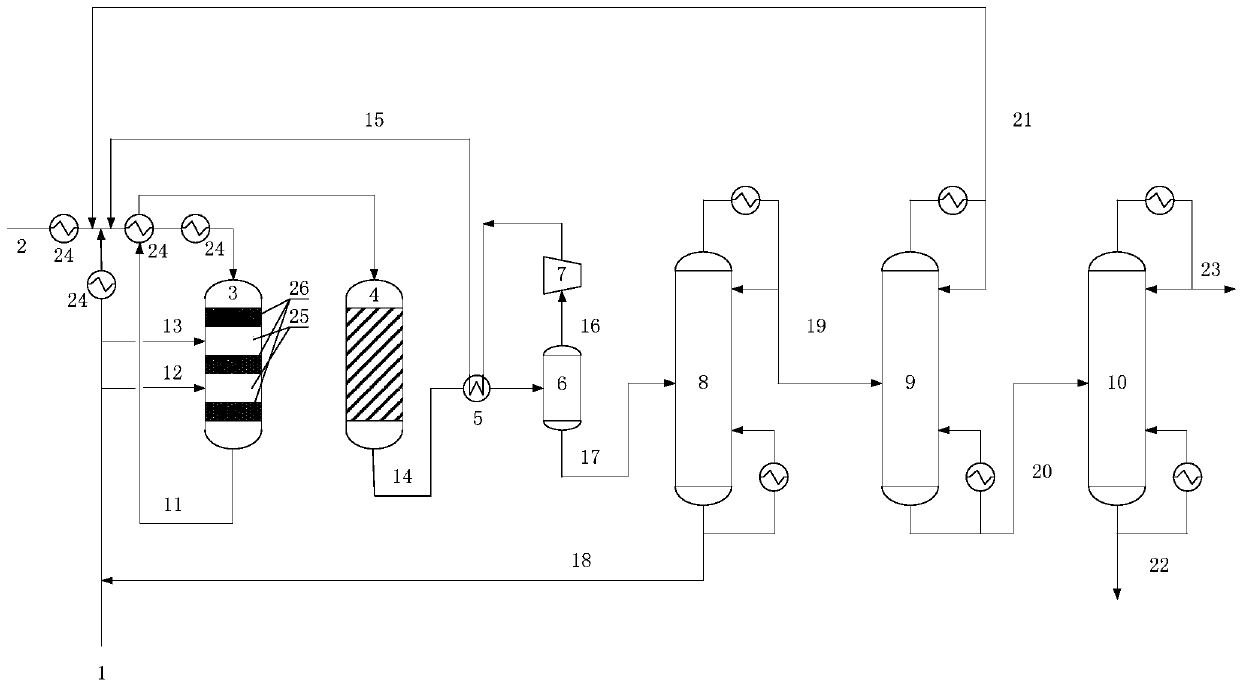

[0034] in such as figure 1In the process flow shown, the acid hydrogenation reactor is a multi-stage fixed bed with three stages of catalyst beds, and the inert material alumina ceramic balls are filled between the beds. The raw material of acetic acid is divided into three strands. The first strand of acetic acid is mixed with hydrogen and vaporized, then enters the acid hydrogenation reactor, and contacts with catalyst I to generate product A containing ethanol and ethyl acetate; Two feed ports in the axial direction of the hydrogenation reactor enter the acid hydrogenation reactor, and the two feed ports are located on the inert material filling area in the acid hydrogenation reactor. The reaction product of the acid hydrogenation reactor directly enters the ester hydrogenation reactor after exchanging heat with the raw material, and the product B of the ester hydrogenation reactor enters the gas-liquid separation tank, and is separated to obtain two phases of gas and liqui...

Embodiment 2

[0038] According to the conditions and steps described in Example 1, the acid hydrogenation reactor catalyst I is a supported platinum metal carrier composite, wherein the supported metals are 1wt% Ru, 1.5wt% Sn, 0.5wt% Ca, 0.5% Re. The acid hydrogenation reactor is a tubular fixed-bed reactor, the catalyst I packing quality is 300g, the feed is hydrogen with a purity of 99.7wt% acetic acid and a purity of 99.8%, and the hydrogen-acid ratio of the entire reaction system is 50:1 , the inlet temperature of the catalytic bed is 280°C, the reaction pressure is 3.5MPa, and the hourly space velocity of the reaction liquid is 1.0h -1 .

[0039] The volume of the ester hydrogenation reactor is 1 / 3 of that of the acid hydrogenation reactor, wherein the catalyst II is a copper-loaded or copper oxide support composite, and the loading quality of the catalyst II is 100g. The inlet temperature of the catalytic bed of the reactor is 200°C, the reaction pressure is 3.44MPa, and the hourly s...

Embodiment 3

[0041] According to the conditions and steps described in Example 1, the acid hydrogenation reactor catalyst I is a supported platinum metal carrier composite, wherein the supported metals are 1wt% Pt, 1.5wt% Sn, 0.5wt% Ca, 0.5% Cu. The acid hydrogenation reactor is a tubular fixed-bed reactor, and the loading quality of the catalyst I is 300g. The feed materials are acetic acid with a purity of 99.7wt% and hydrogen with a purity of 99.8%, and the hydrogen-acid ratio of the entire reaction system is 50:1. The inlet temperature of the catalytic bed of the reactor is 250°C, the reaction pressure is 3.5MPa, and the hourly space velocity of the reaction liquid is 1.0h -1 .

[0042] Catalyst II of the ester hydrogenation reactor does not contain copper or copper oxide carrier complex, the inlet temperature of the catalytic bed of the reactor is 200°C, the reaction pressure is 3.44MPa, and the hourly space velocity of the reaction liquid is 1.0h -1 , the hydrogen ester molar ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com