Collision type separator and biomass comprehensive utilization system

A separator and biomass technology, applied in the fields of biofuels, separation methods, dispersed particles separation, etc., can solve the problems of poor decoking effect of dry purification, difficult separation of tar and acetic acid, etc., and achieve good decoking effect and process flow. Increase, improve the effect of defocusing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present invention provide a collision separator and a biomass comprehensive utilization system, which solves the technical problems in the prior art that the dry purification decoking effect is poor and the tar and acetic acid produced are difficult to separate, and improves the decoking effect , can realize the separation of tar and acetic acid liquid, and reduces the industrial cost.

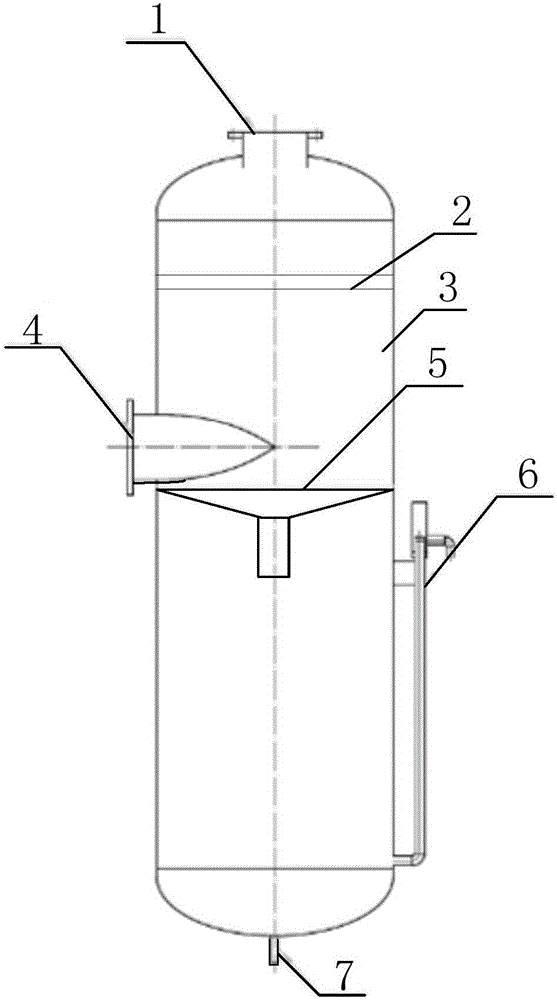

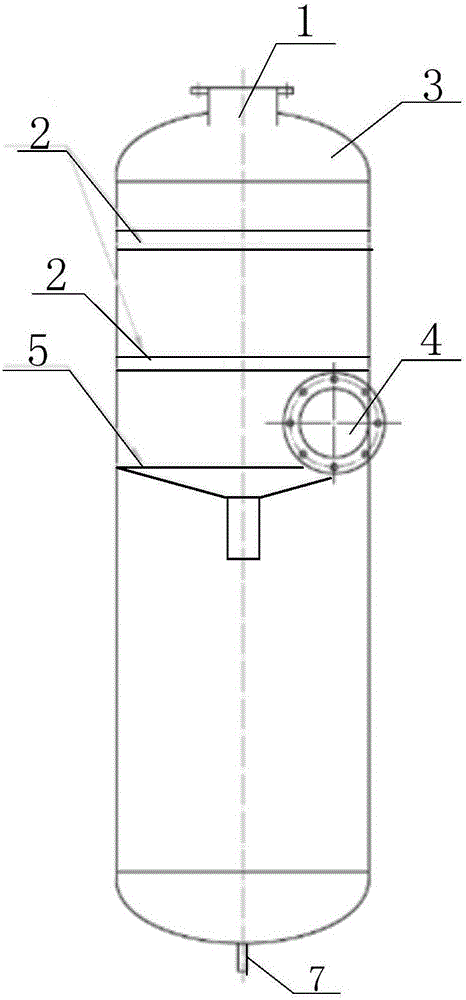

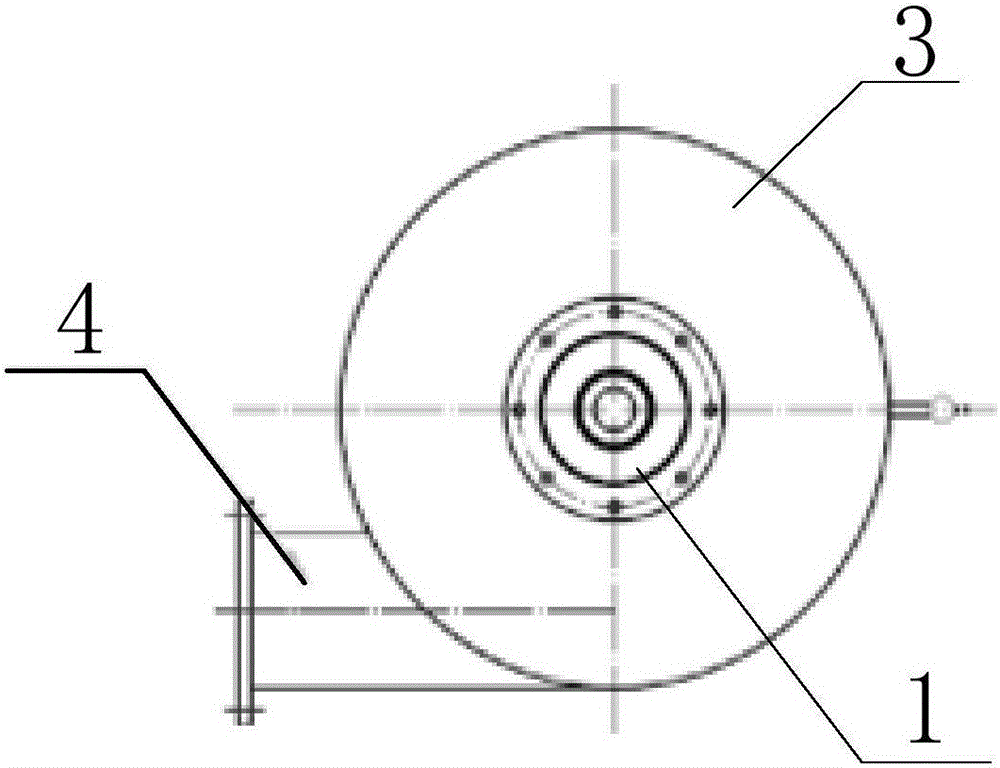

[0046] see figure 1 , The embodiment of the present invention provides a collision separator, which includes an intake pipe 4 , an exhaust pipe 1 , a separator body 3 , a turbine blade 2 , a collection device 5 , a separation device 6 and a sewage discharge device 7 . The separator body 3 has a cylindrical structure, the air inlet pipe 4 communicates with the separator body 3 , and the air inlet pipe 1 is arranged tangentially to the separator body 3 . The input end of the air intake pipe 4 is arranged outside the separator body 3, the output end of the air intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com