Flavor-quality modifier for food, manufacturing method thereof and food processed by same

A quality improver and flavor technology, applied in food ingredients as taste improver, food preparation, food preservation, etc., can solve the problems of food quality reduction, health impact of eaters, reduction of food flavor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of Flavor Quality Improver

[0062] [Table 1-1]~[Table 1-4] The formulations (flavor quality improvers) were prepared by mixing the powder of each inorganic phosphate and the Glycerin fatty acid ester or sucrose fatty acid ester is added to acetic acid solution, and oil is added according to the situation to emulsify and disperse the mixed, adsorbed and powdered or pasted. There is also a case where heat is generated during mixing and the temperature rises to about 60°C. After cooling naturally, grind with a mortar and sieve through a sieve with an opening of 2mm. Next, preparations are prepared by mixing the obtained powder or paste with other ingredients such as various preservatives or organic acids and amino acids as necessary.

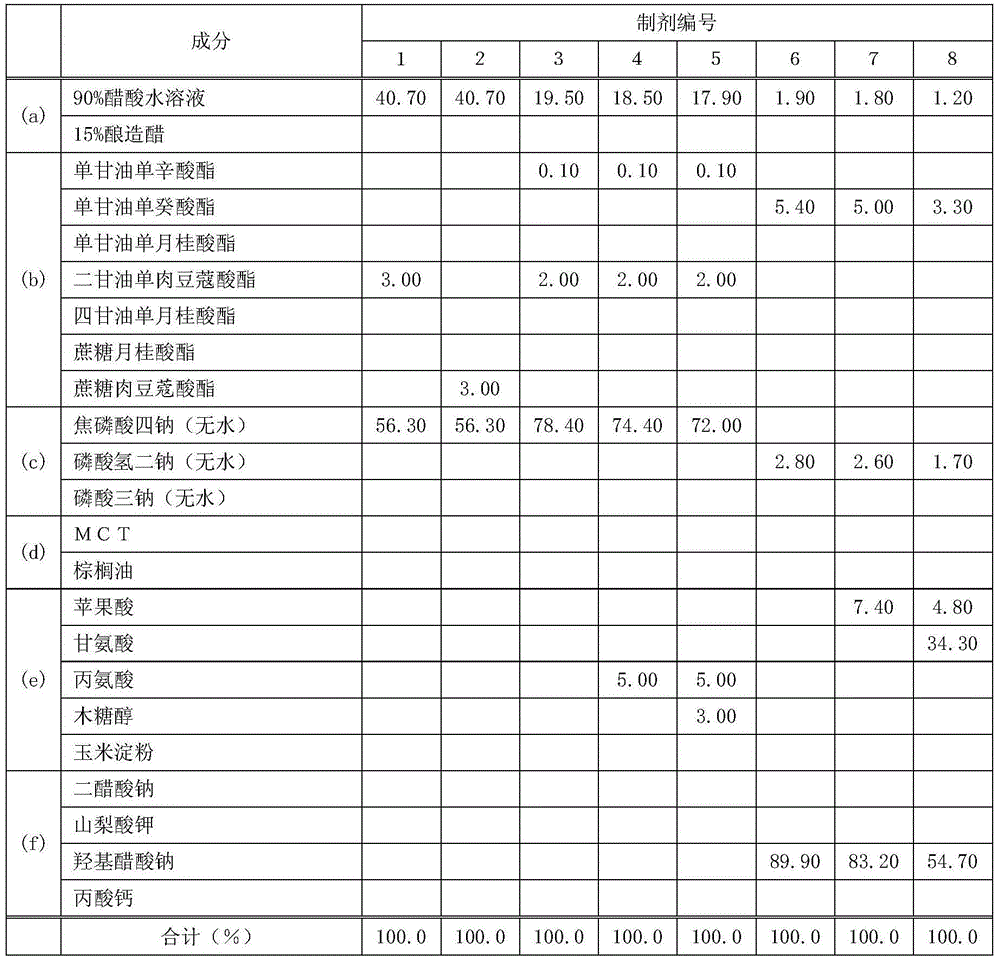

[0063] 【Table 1-1】

[0064]

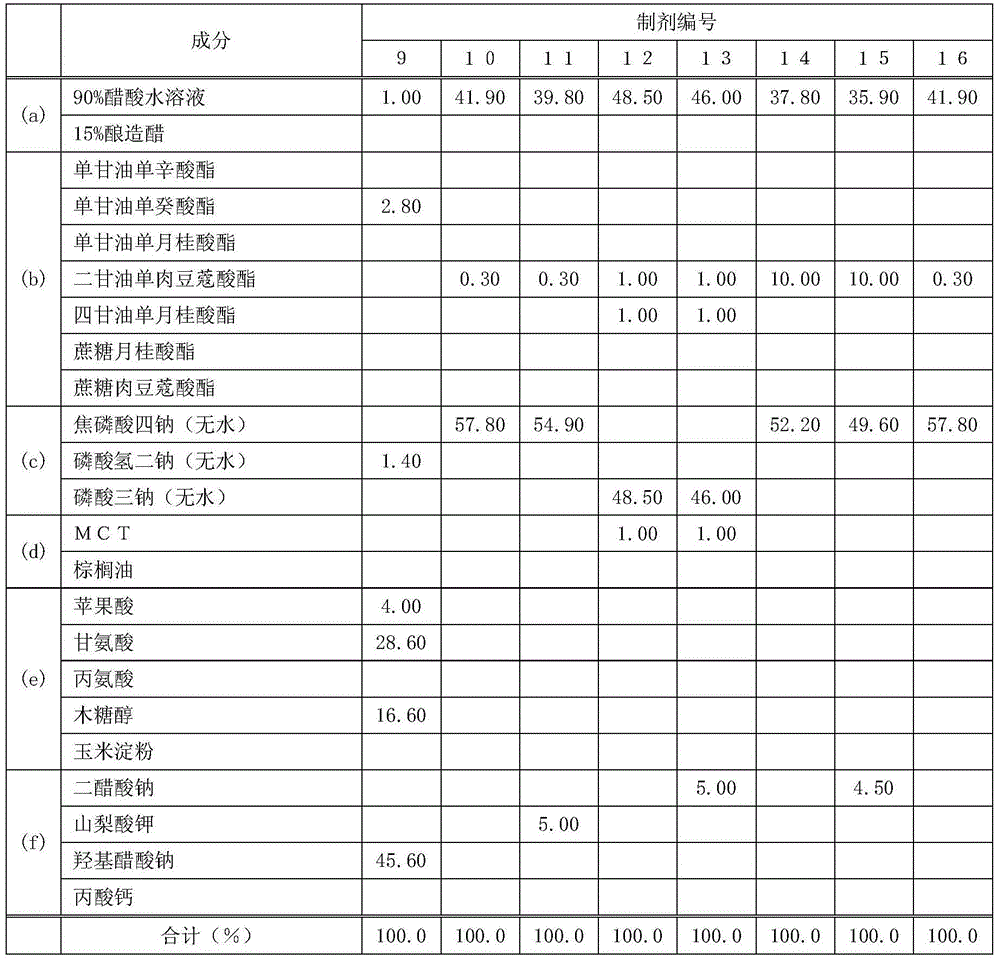

[0065] 【Table 1-2】

[0066]

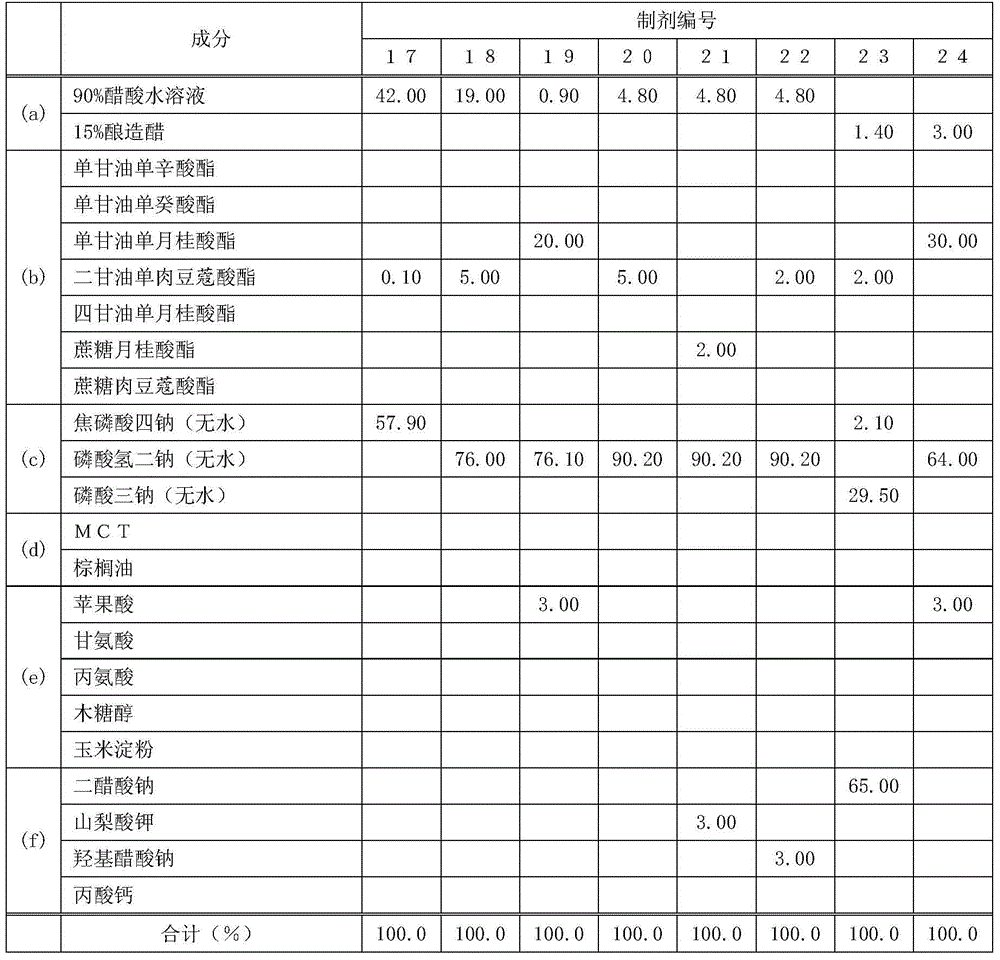

[0067] 【Table 1-3】

[0068]

[0069] 【Table 1-4】

[0070] The specific use is as follows: [Table 1-1], [Table 1-2], [Table 1-3] and [Table 1-4] recorded...

Embodiment 2

[0072] hamburger

[0073] Mix the ingredients of the following [Table 2-1] formula and each additive to form a 50g piece, and heat it in a preheated 250°C oven for 10 minutes. After cooling to avoid secondary pollution, store at 30°C, and observe the number of viable bacteria (CFU / g) in the sample to be tested over time ([Table 2-2]).

[0074] Moreover, flavor quality was observed by 10 skilled panelists.

[0075] 【table 2-1】

[0076] Hamburger Recipe

[0077] Material

parts by weight

Minced meat (cattle: pig = 1:1)

400 copies

chopped onion

100 copies

egg

50 copies

water

30 copies

Flour

25 copies

Salt

4.5 servings

black pepper

0.5 parts

total

610.0 copies

[0078] The amount of additives added (to the total weight of the hamburger)

[0079] Trial No. 2 - (1) No addition

[0080] Test No. 2 - (2) Diglycerol Monomyristate 0.015% by weight

[0081] Test No. 2-(3)...

Embodiment 3

[0128] 【bread】

[0129] Mix the following [Table 3-1] ingredients (except for shortening) and the formulation with a mixer (use a kitchen aid type made by F·M·I Co., Ltd. - mixer type: KSM5), and knead for 7 minutes (kneading Speed: No.2 is 3 minutes, No.6 is 4 minutes). After adding shortening, knead for 9 minutes (kneading speed: 3 minutes for No. 3, 6 minutes for No. 6. Kneading temperature: 26.5°C).

[0130] This is followed by the first fermentation (32°C, 90 minutes). Next, after stamping (rounding), enter the Floor-Time step (32°C, 30 minutes). Next, after dividing the material into 220 g, it was left to stand at room temperature for 10 minutes as a bench-time. After degassing the billet and forming it, it is fired at 190°C for 34 minutes after the furnace step (final fermentation: 39°C, 45 minutes). After firing, cool down to avoid secondary pollution, apply 0.1ml of the bacterial solution to 24 spots on the longitudinal section of the bread, pack it simply, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com