Preparation method of drinking water treatment agent

A technology of chitosan microspheres and tourmaline, which is applied in the field of water treatment, can solve the problems of water purification by water purifiers that have not yet been seen, and achieve the effects of remarkable treatment effect, simple preparation method, and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A water treatment agent is prepared in the following steps:

[0027] a. Pretreatment of tourmaline

[0028] Crush tourmaline through a 200-mesh sieve, wash 5-7 times with NaOH solution with a mass concentration of 5% to remove the anions and cations attached to the surface, and then wash with deionized water for the same number of times, then put it in an oven to dry, and wait for use;

[0029] b. Preparation of superparamagnetic Fe3O4 powder

[0030] Weigh 5.56g FeSO 4 ·7H 2 O, 6.5g FeCl 3 and 1.7mL of concentrated hydrochloric acid were dissolved in 50mL of N 2Degas the distilled water, then add the above dropwise to 250mL of 1.0mol / L NaOH solution; stir in a water bath at 80°C at a slow speed (100r / min) for 5min, then stir mechanically at a rapid speed (2000r / min), and wait for the solution A black precipitate appeared in the solution, and the stirring was continued for 30 minutes; after the reaction was completed, it was left to cool down to room temperature, ...

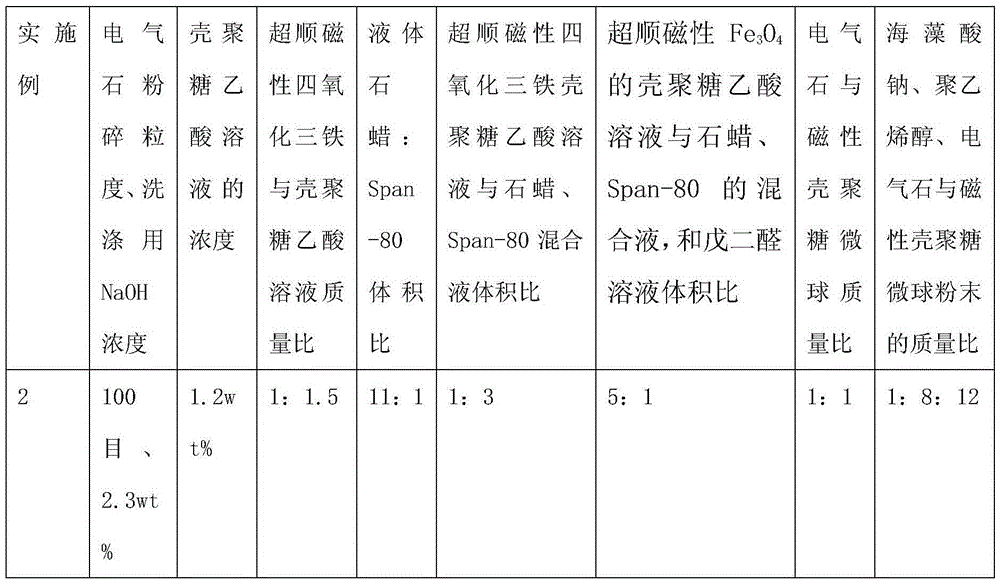

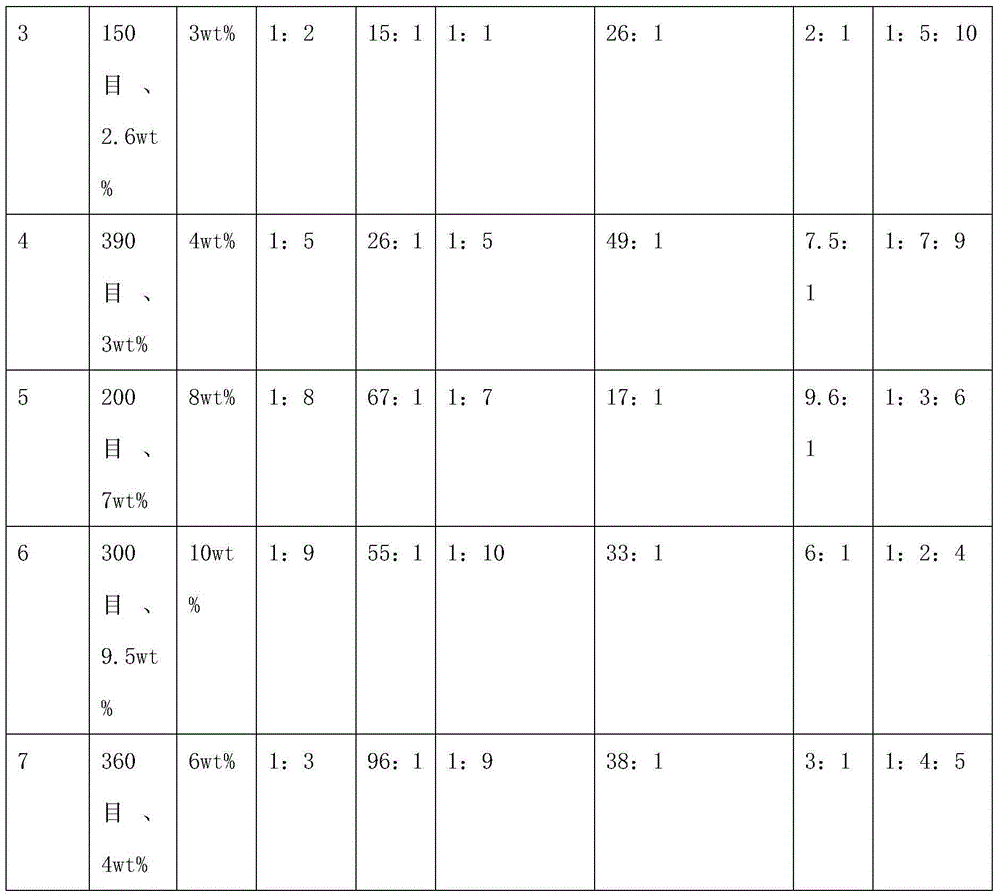

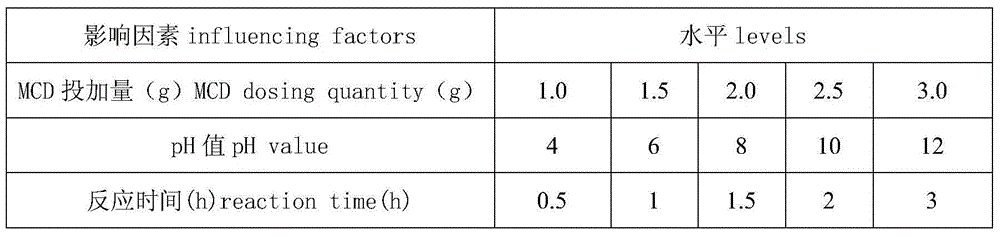

Embodiment 2~7

[0035] Embodiment 2~7: carry out by following each material and step, all the other are with embodiment 1.

[0036]

[0037]

[0038] The removal rate of the tourmaline / magnetic chitosan microspheres prepared above is 78% to 90% for the volatile phenol in the source water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com