Biomass pyrolysis method

A biomass and rectangular container technology, used in biofuels, air quality improvement, special forms of dry distillation, etc., can solve the problems of not achieving environmental protection and energy saving, inaccurate extraction components, poor carbonization effect, etc., and achieve high gasification rate. Accurate effect of extracting ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

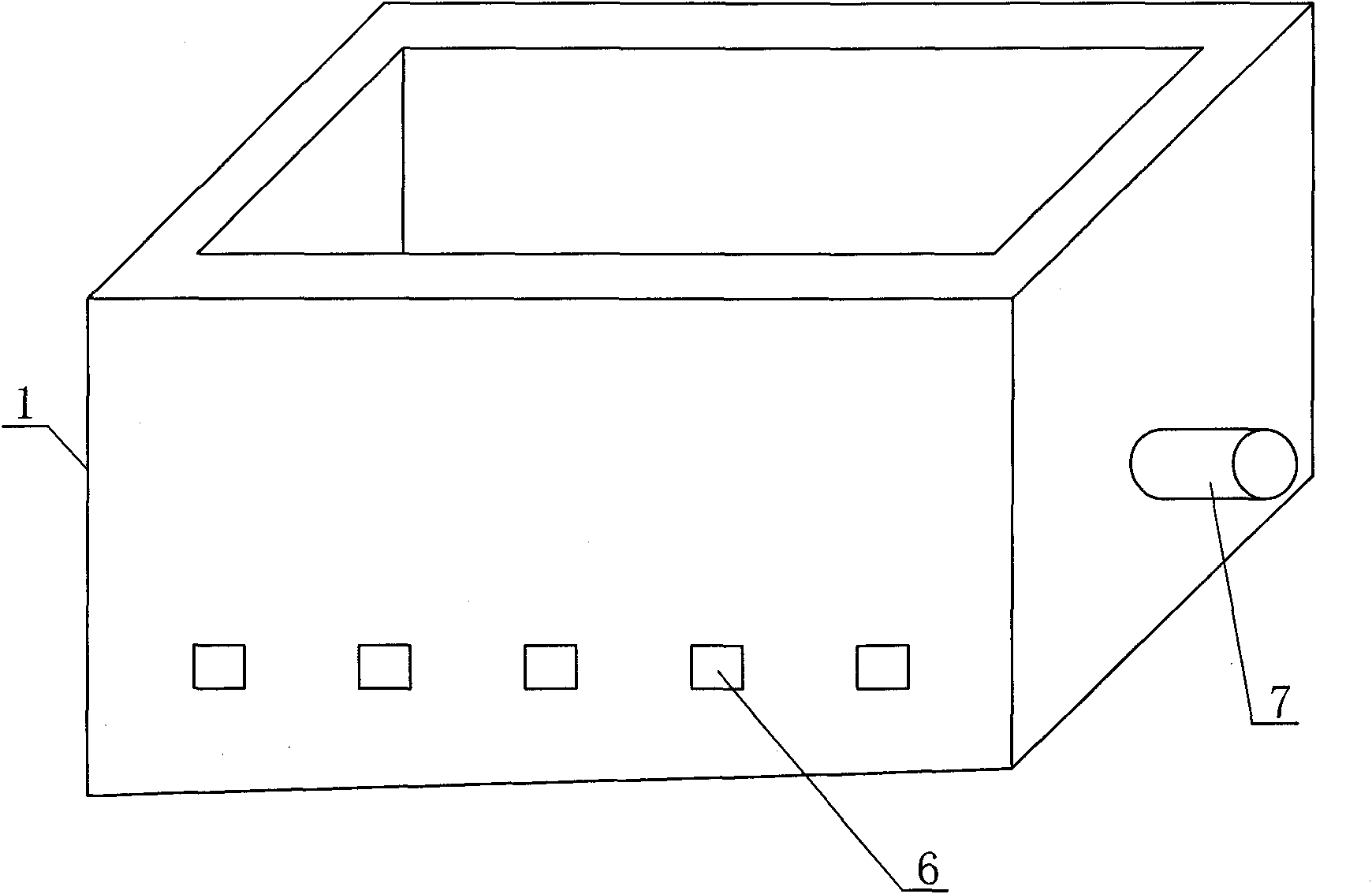

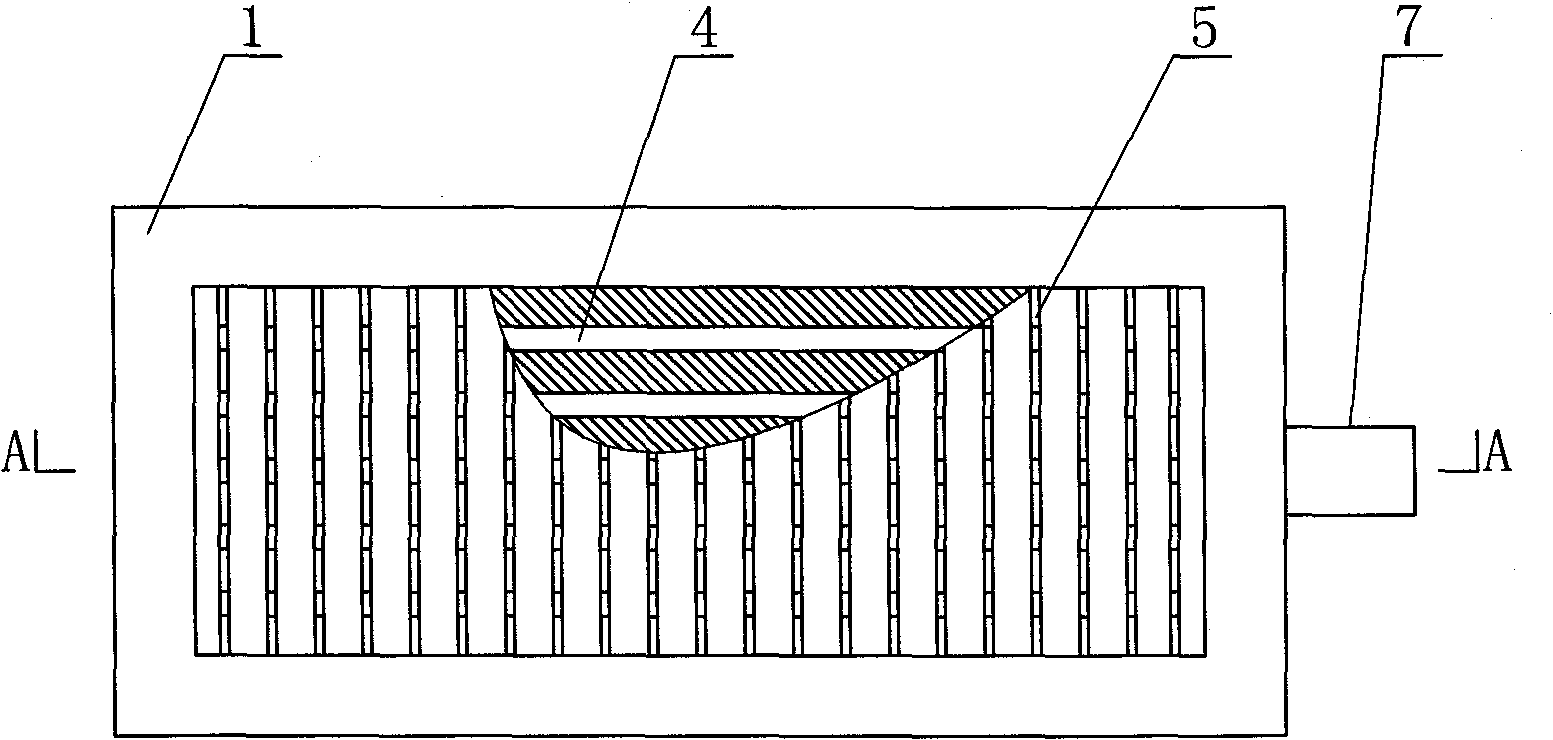

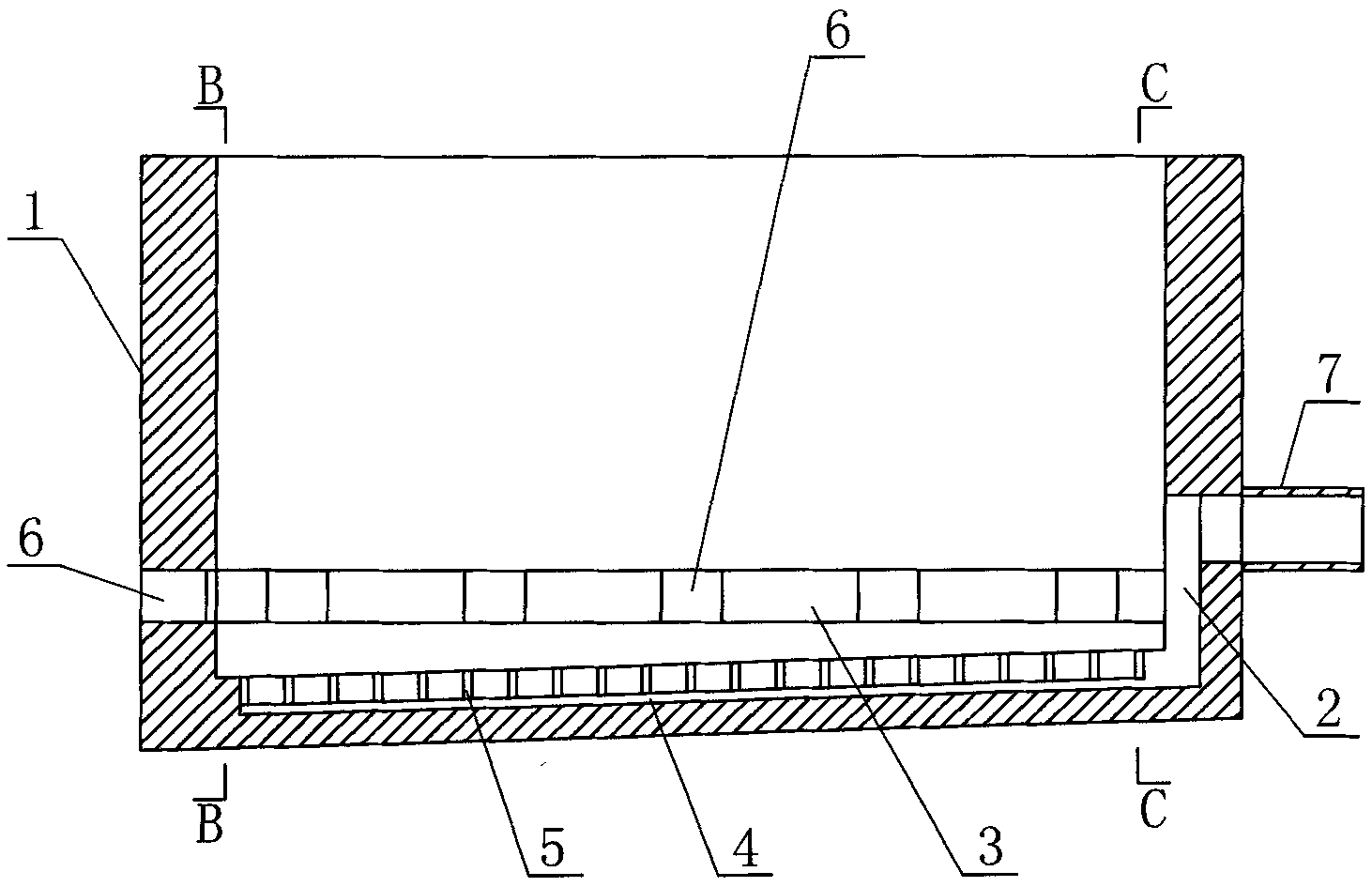

[0016] Depend on figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 It can be seen that the bottom plane of the open rectangular container 1 used in the biomass cracking method of the present invention is inclined, and the short wall of the container 1 is provided with a flue 2 along the bottom, and the other three walls are provided with an air duct 3 along the bottom. 2. It communicates with several ventilation passages 4 inside the bottom of the container 1. The bottom surface of the container 1 is provided with a plurality of suction passages 5 and communicates with each ventilation passage 4. The container wall and the bottom of the container are provided with ventilation holes 6. 7 is connected with the flue 3 and connected with the cooling device in the next step. The container 1 is made of refractory material and iron plate, and can be installed in half of the ground and half of the ground.

[0017] Taking the volume of 60 cubic meters as an example, the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com