Condensation type purifying series apparatus for combustible gas from biomass pyrolysis

A biomass pyrolysis and condensation technology, which is applied in the direction of condensing non-gaseous material gas purification, gas dust removal, etc., can solve the problems of inability to purify combustible gas with high quality, increase production costs, waste by-products, etc. The effect of preventing secondary pollution and reducing production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

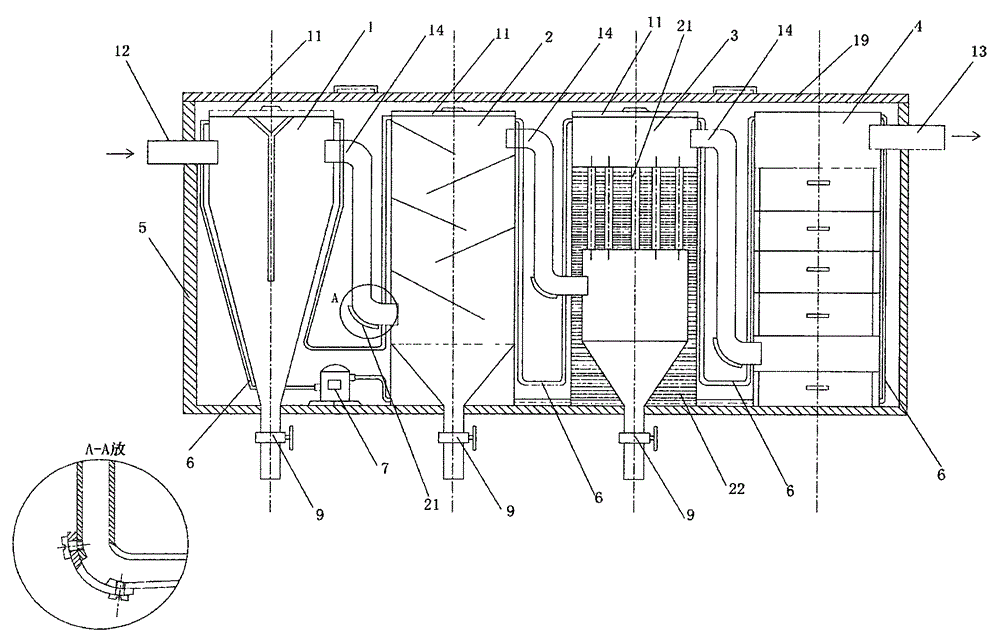

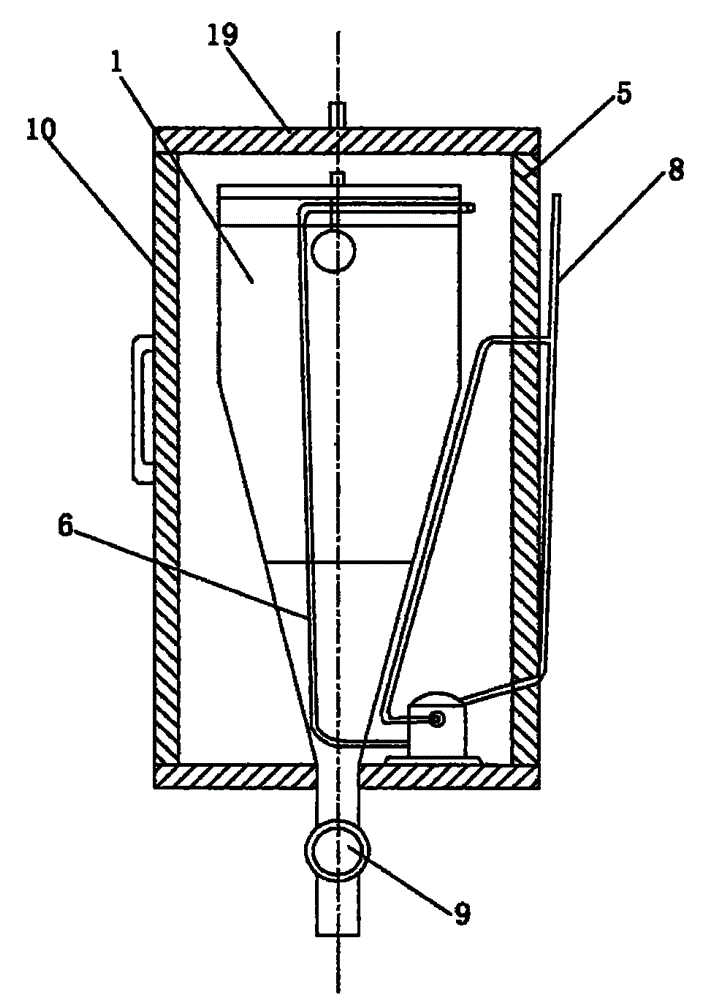

[0014] Depend on figure 1 It can be seen that the biomass pyrolysis combustible gas condensing type purification series device of the present invention includes a dust gravity type separator (1), a collision interception type separator (2), a condensation type oil-water separator (3), a multi-layer filter purifier ( 4) They are integrated in a refrigeration box and connected to each other as a series of purification devices through pipes (14). The evaporator coils (6) in the refrigeration box are all along the outer wall circumference of these four purification devices and are connected with the refrigeration compressor. The machine (7) is connected to form a complete refrigeration system, and the cooling effect in the box is produced.

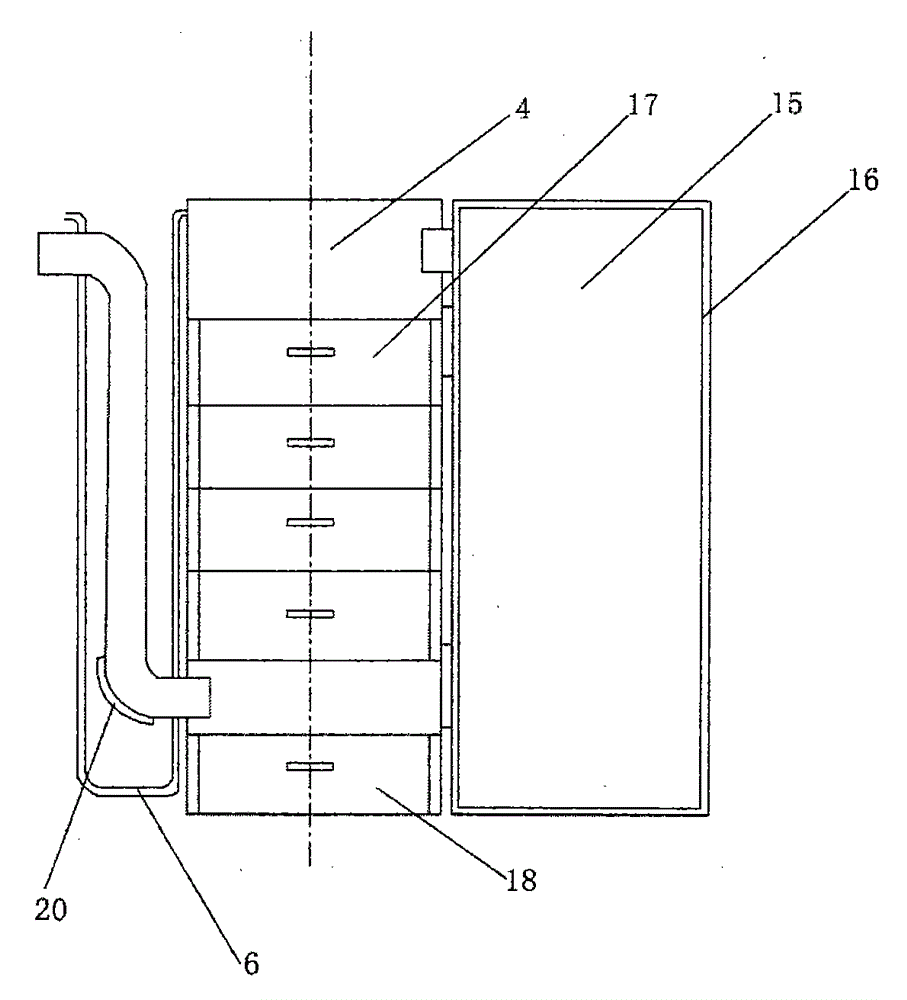

[0015] see figure 2 Shown multi-layer filter purifier is the cabinet body that is provided with door (15), and magnetic rubber strip (16) is installed on the inner edge of door (15) frame, similar refrigerator door. The cabinet above the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com