Ethanol production method

A technology of ethanol and catalyst, which is applied in the field of ethanol production, can solve the problems of low single pass conversion rate, poor selectivity, harsh catalyst reaction conditions, etc., and achieve the effect of mild reaction conditions, good technical effect, and good catalyst activity selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

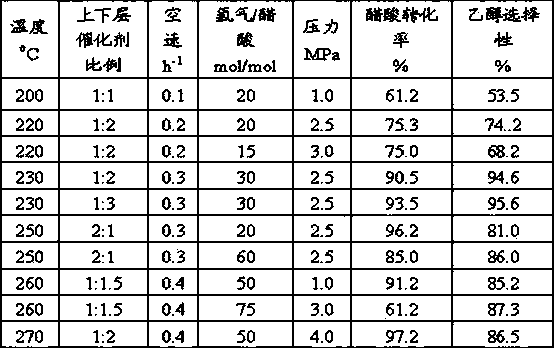

Embodiment 1

[0040] Catalyst 1 is used as the upper bed, catalyst 6 is the lower bed, the weight ratio of the upper and lower beds is 1:2, pure acetic acid is used as the raw material, and the upper and lower bed catalyst weight ratio is 1:2, the inlet reaction temperature is 230 °C, and the hydrogen pressure is 2.5 MPa , H 2 The molar ratio to acetic acid is 30, and the volume space velocity of the liquid phase raw material is 0.3 h -1 The reaction was carried out under certain conditions, and the catalytic results are shown in Table 2.

[0041]

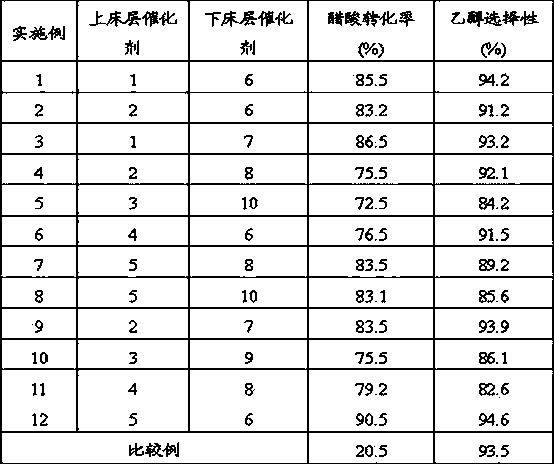

Embodiment 2~12

[0043] The catalyst used is shown in Table 2, with pure acetic acid as raw material, at the inlet reaction temperature of 230 ° C, hydrogen pressure of 2.5 MPa, H 2 The molar ratio to acetic acid is 30, and the volume space velocity of the liquid phase raw material is 0.3 h -1 The reaction was carried out under certain conditions, and the catalytic results are shown in Table 2.

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com