Magnetic-field measurement device and manufacturing method thereof as well as magnetic-field measurement method

A magnetic field measurement and optical fiber technology, which is applied in the field of magnetic field measurement devices, can solve the problems of time-consuming, time-consuming, and the confocal microscope system is not easy to transplant, and achieves the effect of saving time and manpower and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

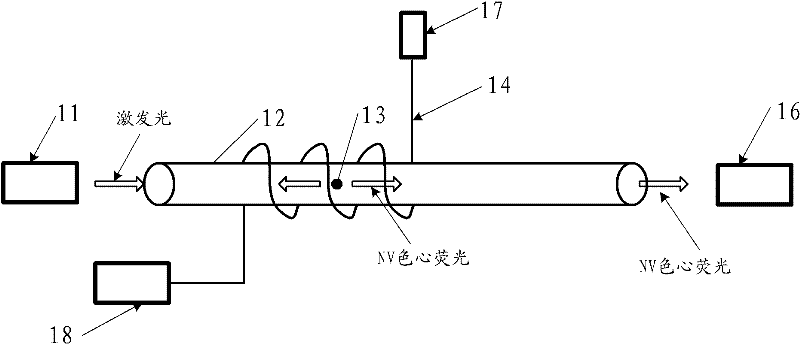

[0072] The structure diagram of the magnetic field measuring device disclosed in this embodiment is as follows: image 3 with Figure 4 As shown, the device includes:

[0073] A combined optical fiber 12 formed by connecting two optical fibers;

[0074] The single-crystal diamond particles 13 with a single NV color center encapsulated between the end faces of the two optical fibers, the single-crystal diamond particles 13 are also in the combined optical fiber 12, and nano-scale or micron-scale is preferably used in this embodiment. Single crystal diamond particles, that is, single crystal diamond particles with a diameter of several nanometers to hundreds of nanometers;

[0075] a microwave transmission line arranged on the outer wall of the combined optical fiber 12;

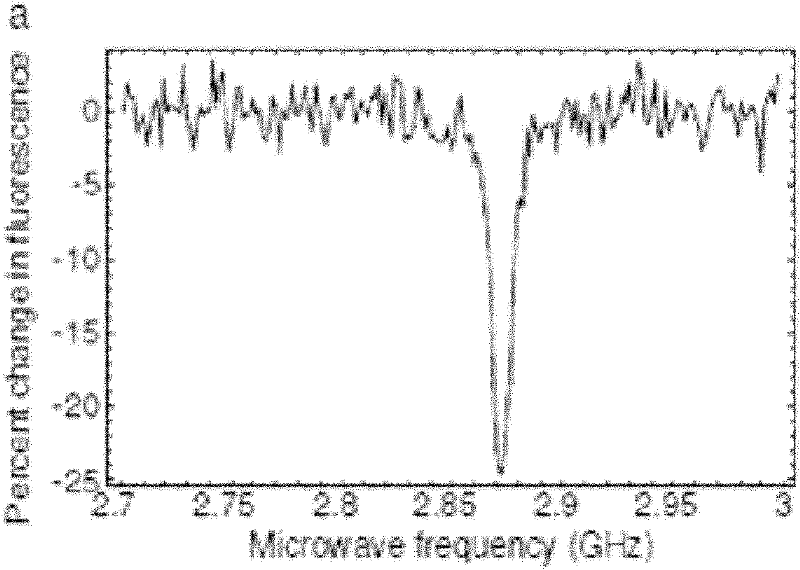

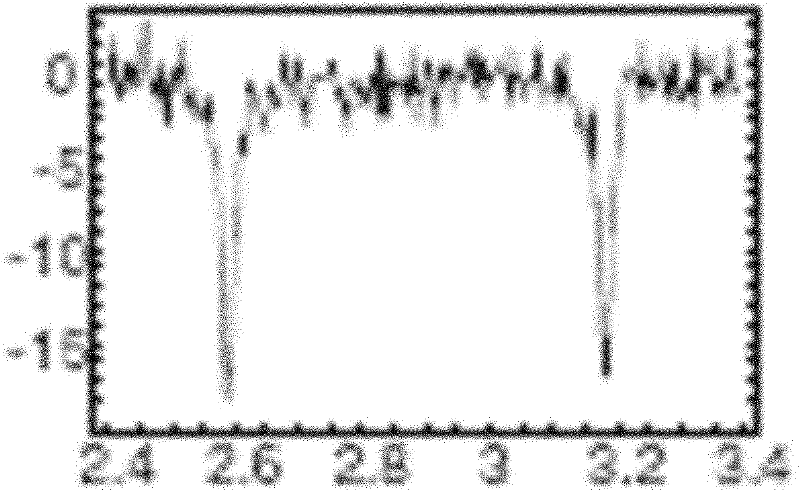

[0076] It should be noted that, if figure 1 with figure 2 As shown, the microwave transmission line is mainly used to transmit microwaves to load the microwaves onto the single NV color center in the com...

Embodiment 2

[0090] Corresponding to the previous embodiment, this embodiment discloses the manufacturing method of the magnetic field measuring device described in the previous embodiment, the flow chart of the method is as follows Figure 5 shown, including the following steps:

[0091] Step S11: fixing two optical fibers, the end faces of the two optical fibers are opposite and located on the same straight line, wherein one optical fiber is connected to a laser to transmit excitation light, and the other optical fiber is connected to a spectrometer;

[0092] Specifically, in the embodiment of the present invention, an optical fiber holder may be used to fix the two optical fibers, especially the opposite end faces of the two optical fibers, so as to ensure the stability of the optical fibers during the packaging process.

[0093] Such as Image 6 As shown, it is a schematic diagram of the placement of two optical fibers. In this embodiment, only the a end face of 1# optical fiber is co...

Embodiment 3

[0133] The flow chart of the magnetic field measurement method disclosed in this embodiment is as follows Figure 8 As shown, the method uses the magnetic field measuring device described in Embodiment 1 to measure the magnetic field strength, and the method includes the following steps:

[0134] Step S21: Input excitation light at one end of the combined optical fiber to excite a single NV color center to generate fluorescence, and connect the other end to a spectrometer so as to measure the fluorescence intensity of the single NV color center in the combined optical fiber at any time, and transmit it in the microwave transmission line Input microwaves of a certain frequency;

[0135] Step S22: using a standard magnetic field to calibrate the single NV color center in the combined optical fiber to obtain the microwave frequency difference corresponding to the magnetic field per unit intensity;

[0136] Step S23: Place the combined optical fiber that has been calibrated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com