Continuous production technology of three kettle type sodium hydrosulfide

A technology of sodium hydrosulfide and production technology, which is applied in the direction of sulfur compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of discontinuous production of sodium hydrosulfide in a single kettle, and achieve the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

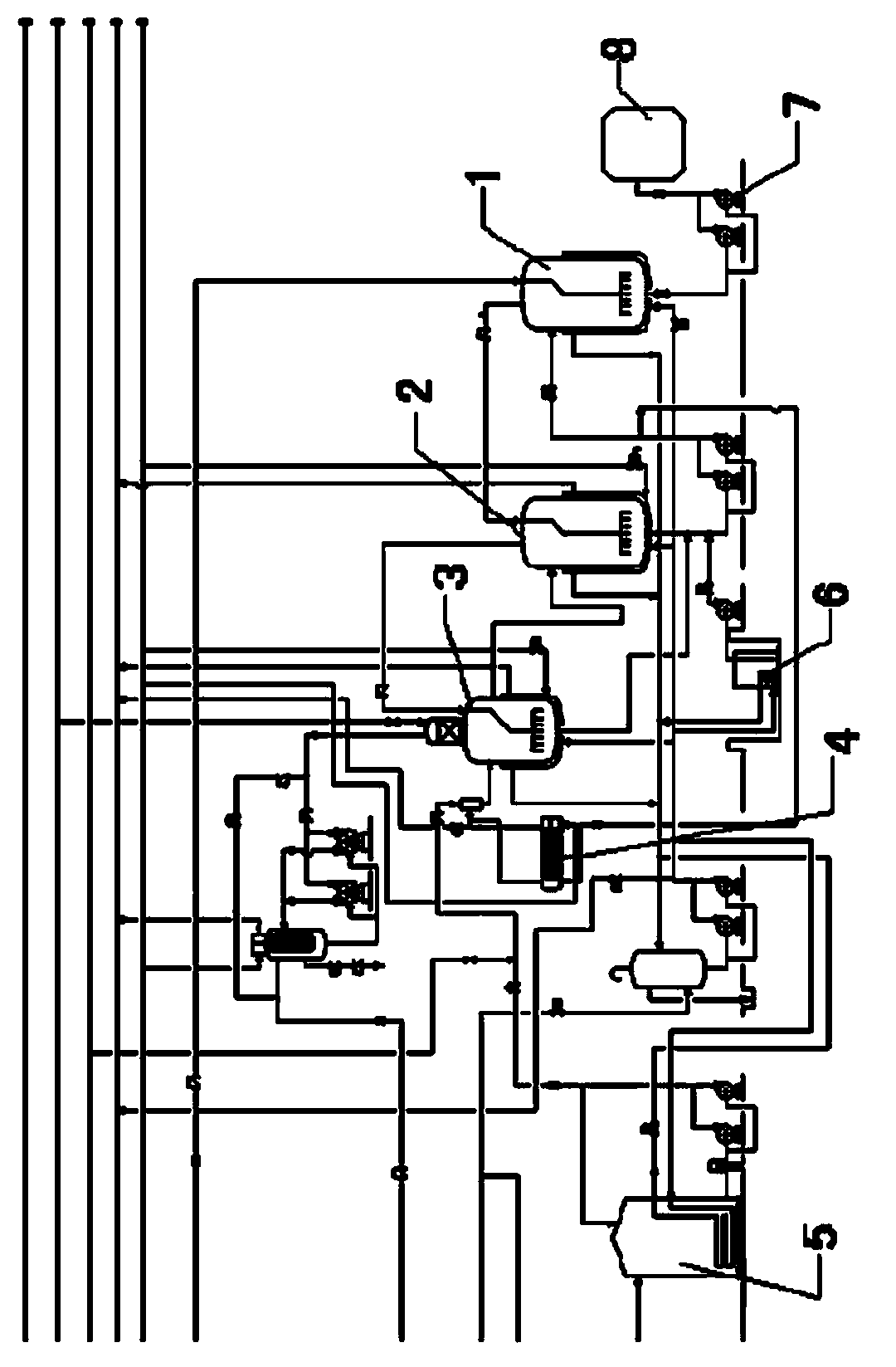

[0019] combined with figure 1 , to further describe the present invention:

[0020] A kind of three kettle formula sodium hydrosulfide continuous production technology is characterized in that: comprise following processing steps:

[0021] (1) The hydrogen sulfide gas first enters the bottom of the first reactor 1 and reacts with the mixed liquid injected from the second reactor 2, and the unreacted gas from the top of the first reactor 1 enters the bottom of the second reactor 2 and reacts with the mixed liquid from the third reactor. The material reaction of kettle 3, the reaction temperature is regulated by the cooling water in the jacket;

[0022] (2) The incomplete reaction gas at the top of the second reactor 2 is cooled by the gas cooler 4 and enters the bottom of the third reactor 3 to fully react with 48% sodium hydroxide solution from the mass percentage of the lye tank 6, the third The reaction material in the upper part of the reactor 3 enters the second reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com