Liquid crystal exposure device

An exposure device and a technology for exposing patterns, which are applied in photolithography exposure devices, microlithography exposure equipment, optics, etc., can solve the problems of residual wrinkles on the substrate and the inability of the substrate to become flat, so as to ensure flatness and shorten production The effect of takt time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

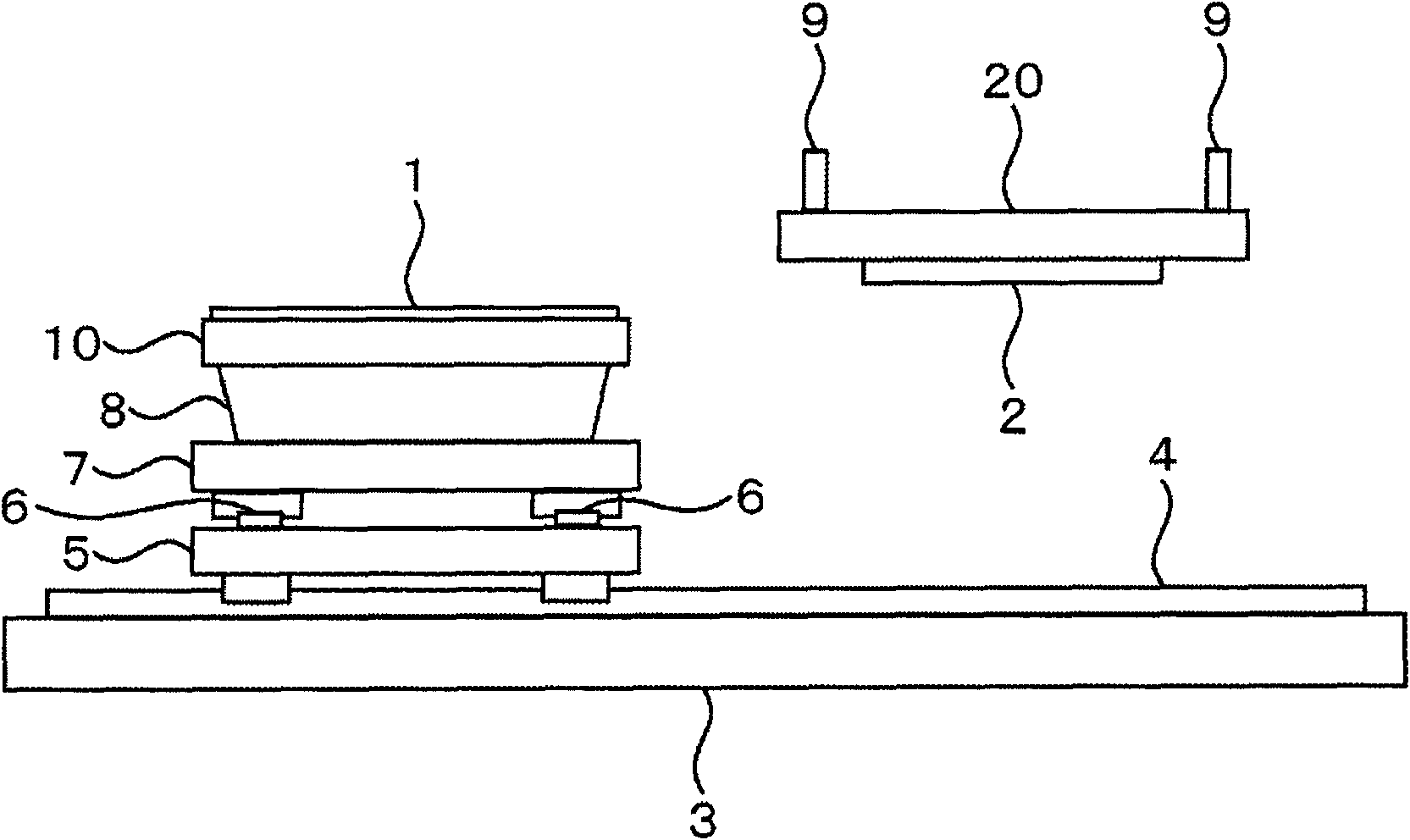

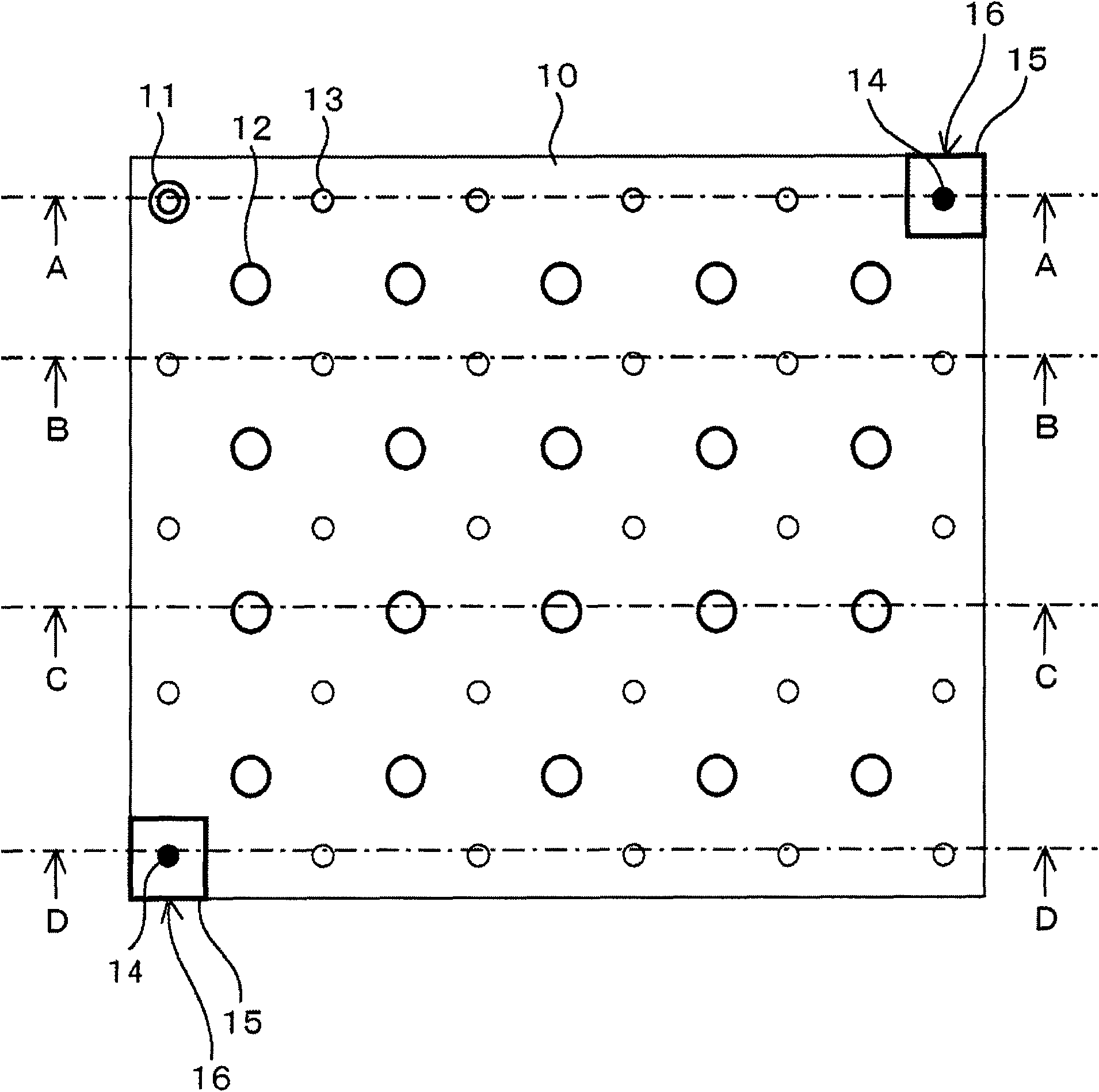

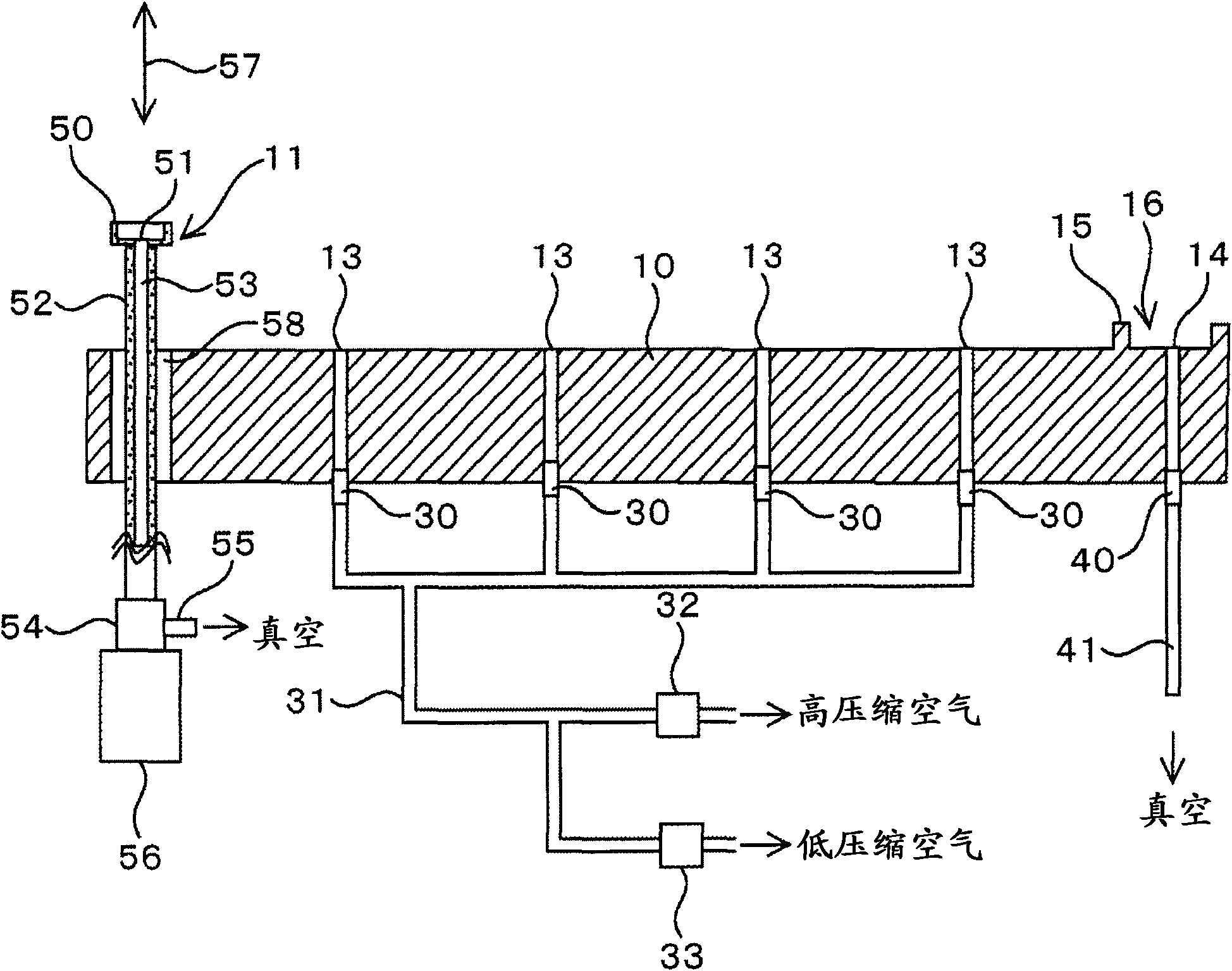

[0077] use Figure 1 to Figure 7 A first embodiment of the present invention will be described.

[0078] figure 1 It is a figure which shows the schematic structure of the exposure apparatus which concerns on one Embodiment of this invention. This embodiment shows an example of an exposure apparatus of a proximity method in which a minute gap (proximity gap) is provided between a mask and a substrate and a mask pattern is transferred to a substrate. The exposure device consists of the following components: base 3, X guide 4, X stage 5, Y guide 6, Y stage 7, θ stage 8, Z-tilt mechanism 9, chuck 10 and mask Die holder 20. In addition, the exposure apparatus includes a light source for exposure, a supply unit for supplying the substrate 1 to the chuck 10 , a recovery unit for recovering the substrate 1 from the chuck 10 , a temperature control unit for controlling the temperature inside the apparatus, and the like.

[0079] exist figure 1 In , the chuck 10 is at the transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com