Exposure device

A technology of exposure device and exposure stage, which is applied to exposure devices in photo-engraving process, exposure equipment for microlithography, optics, etc. The effect of shortening, less elongation or deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

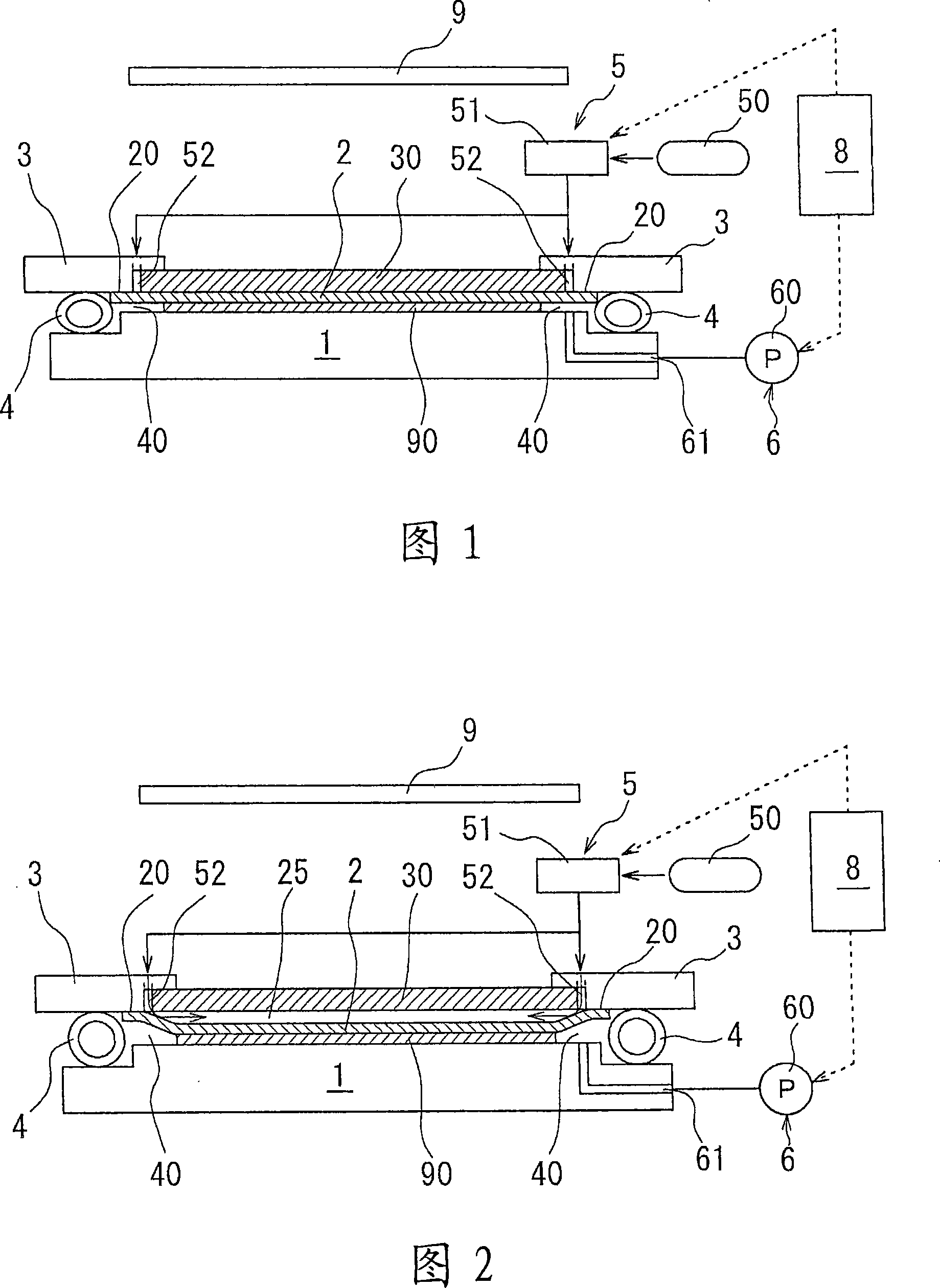

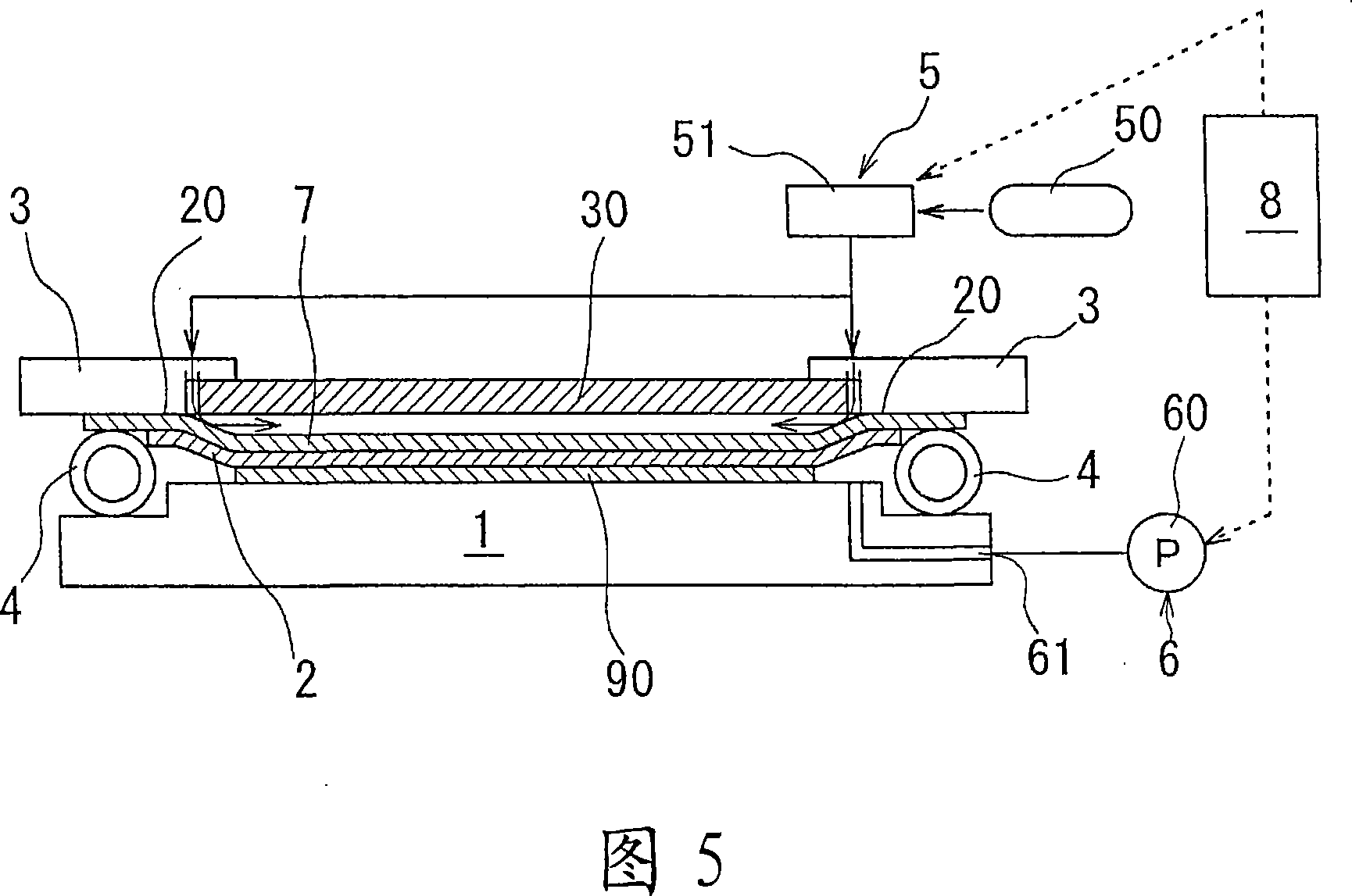

[0025] Embodiments of the exposure apparatus for manufacturing a printed wiring board according to the present invention will be described below with reference to the drawings.

[0026] In FIG. 1 , a substrate 90 for printed wiring to which a photoresist is applied is placed on an exposure table 1 . The exposure stage 1 can move in the XY direction and can move up and down. It can also be turned in the horizontal direction. Explanations on these moving, elevating and rotating mechanisms are omitted.

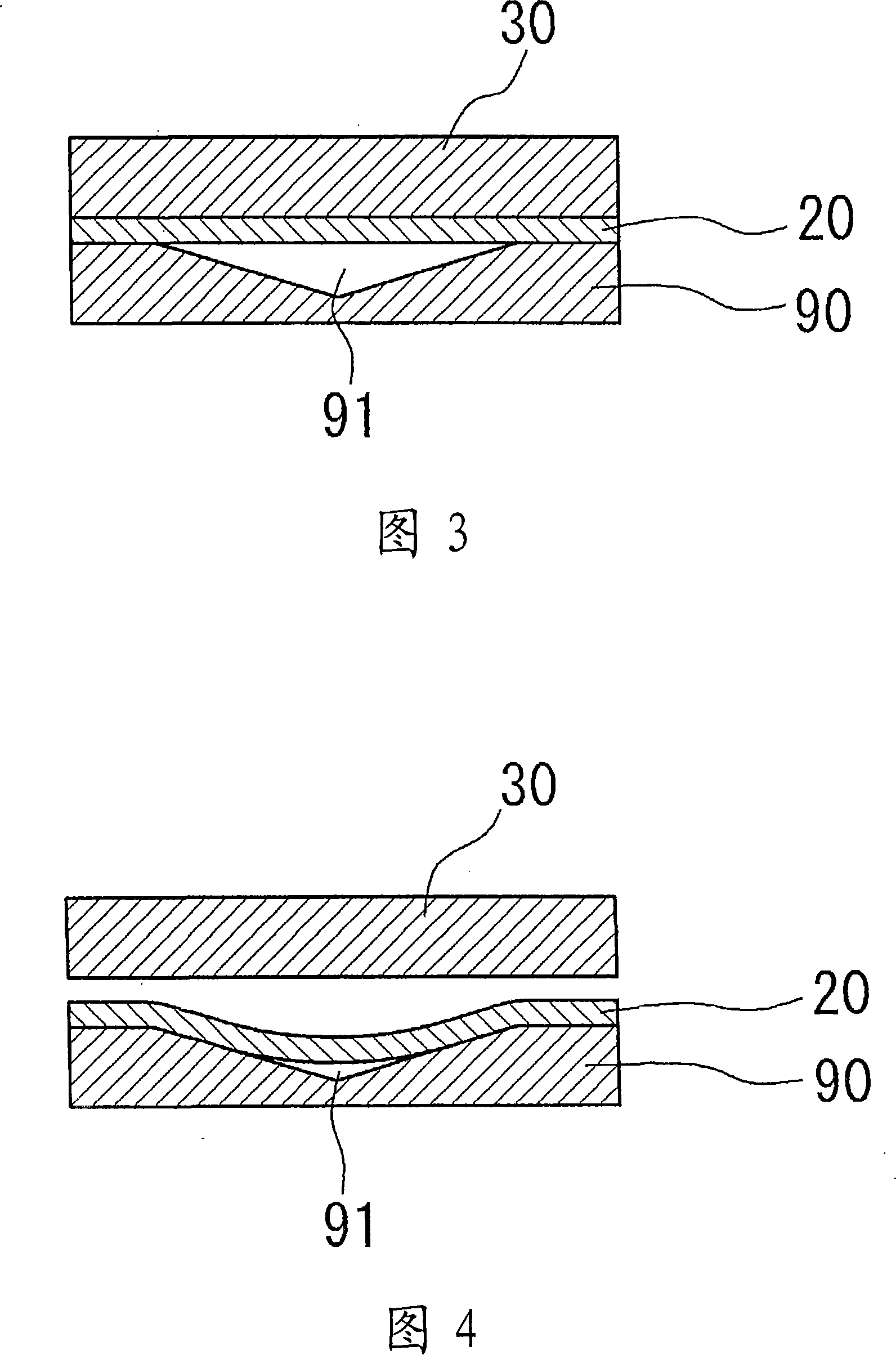

[0027] The film mask 2 on which the circuit pattern is drawn is placed facing the substrate 90 , and the film mask 2 is brought into close contact with the substrate 90 , and the circuit pattern is burned on the substrate 90 by exposure from the light source 9 .

[0028] In addition, although the exposure table 1 and the substrate 90 are arranged in the vertical direction in FIG. 1 , it is not limited to this, and may be arranged in reverse, or may be arranged vertically with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com