Vulcanized rubber with self-repairing and recyclability characteristics as well as preparation method and application thereof

A vulcanized rubber and self-repairing technology, which is applied in the field of vulcanized rubber and its preparation, can solve the problems of harsh reaction conditions, waste of rubber resources, complicated process, etc., and achieve the effects of simple method, prolonging service life and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

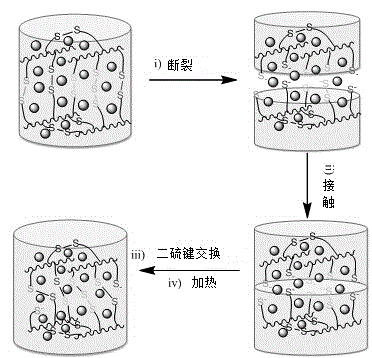

Method used

Image

Examples

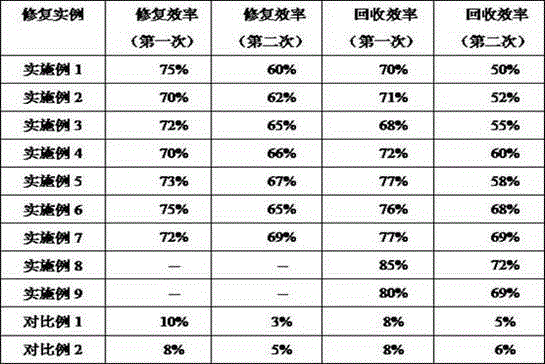

Embodiment 1

[0048] 100 parts of butadiene rubber, 20 parts of pre-grafted nano-silica (the pre-grafting process is: disperse 100 parts of Branches (bis-[γ-(triethoxysilyl)propyl]tetrasulfide, bis-3-(triethoxysilylpropyl)-disulfide, or a mixture of two), After reacting at 80~110°C for 6~12h, filter, wash, and dry to obtain grafted nano-silica), 5 parts of carbon black, bis-[γ-(triethoxysilyl)propane Base] 10 parts of tetrasulfide, 0.1 part of copper chloride, 1 part of zinc oxide, 0.5 part of stearic acid, 1 part of tris(2,4-di-tert-butyl)phenylphosphite, 1 part of 2,2,4-tri 1 part of methyl-1,2-dihydroquinoline polymer, 1 part of bis(1,5-pentylidene) thiuram tetrasulfide, and 1 part of sulfur were mixed uniformly on a double-roller mill in turn to prepare Get the rubber compound. After the rubber mixture was parked at room temperature for 8 hours, it was vulcanized at 150°C to form a 2mm sheet. After being parked at room temperature for 24 hours, the mechanical properties of the materia...

Embodiment 2

[0050] With 100 parts of butadiene rubber, 10 parts of nano-silica of pre-grafting treatment (the pre-grafting process is the same as Example 1), 15 parts of carbon black, two-3-(triethoxysilylpropyl)- 10 parts of disulfide, 0.4 parts of ferric chloride, 1 part of zinc oxide, 0.5 parts of stearic acid, 2 parts of 2,2'-methylenebis-(4-methyl-6-tert-butylphenol), N 1 part of -(1,3-dimethyl)butyl-N'-phenyl-p-phenylenediamine, 0.5 part of bis(1,5-pentylidene)thiuram tetrasulfide, 1 part of sulfur, in turn in bis Mix evenly on the roller mill to make the mixed rubber. After the rubber mixture was parked at room temperature for 8 hours, it was vulcanized at 150°C to form a 2mm sheet. After being parked at room temperature for 24 hours, the mechanical properties of the material were measured by tensile testing. After the tensile spline was broken, the two sections were fully contacted, repaired in the air at 110°C for 12 hours, and the tensile properties of the material were tested ...

Embodiment 3

[0052] With 100 parts of butadiene rubber, 15 parts of nano silica through pre-grafting treatment (the pre-grafting process is the same as in Example 1), 10 parts of carbon black, 12 parts of diallyl disulfide, cuprous chloride 1 part, 0.5 parts of zinc oxide, 0.5 parts of stearic acid, 2 parts of pentaerythritol diisodecyl diphosphite, 2 parts of 2, 6-di-tert-butyl-4-methylphenol, 2 parts of tetraethyl turmeric disulfide 1 part of sulfur and 1.5 parts of sulfur were mixed evenly on a double-roll mill in turn to obtain a rubber compound. After the rubber mixture was parked at room temperature for 8 hours, it was vulcanized at 150°C to form a 2mm sheet. After being parked at room temperature for 24 hours, the mechanical properties of the material were measured by tensile testing. After the tensile spline was broken, the two sections were fully contacted, repaired in the air at 110°C for 12 hours, and the tensile properties of the material were tested again; then the vulcanized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com