Preparation technology of super pure coal

A preparation process, anthracite technology, applied in solid separation, grain processing, etc., can solve the problems of high energy consumption for finely crushed materials, reduce product ash content, unfavorable ultra-pure coal, etc., achieve no need for power, reduce operating costs, and prevent pollution of clean coal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

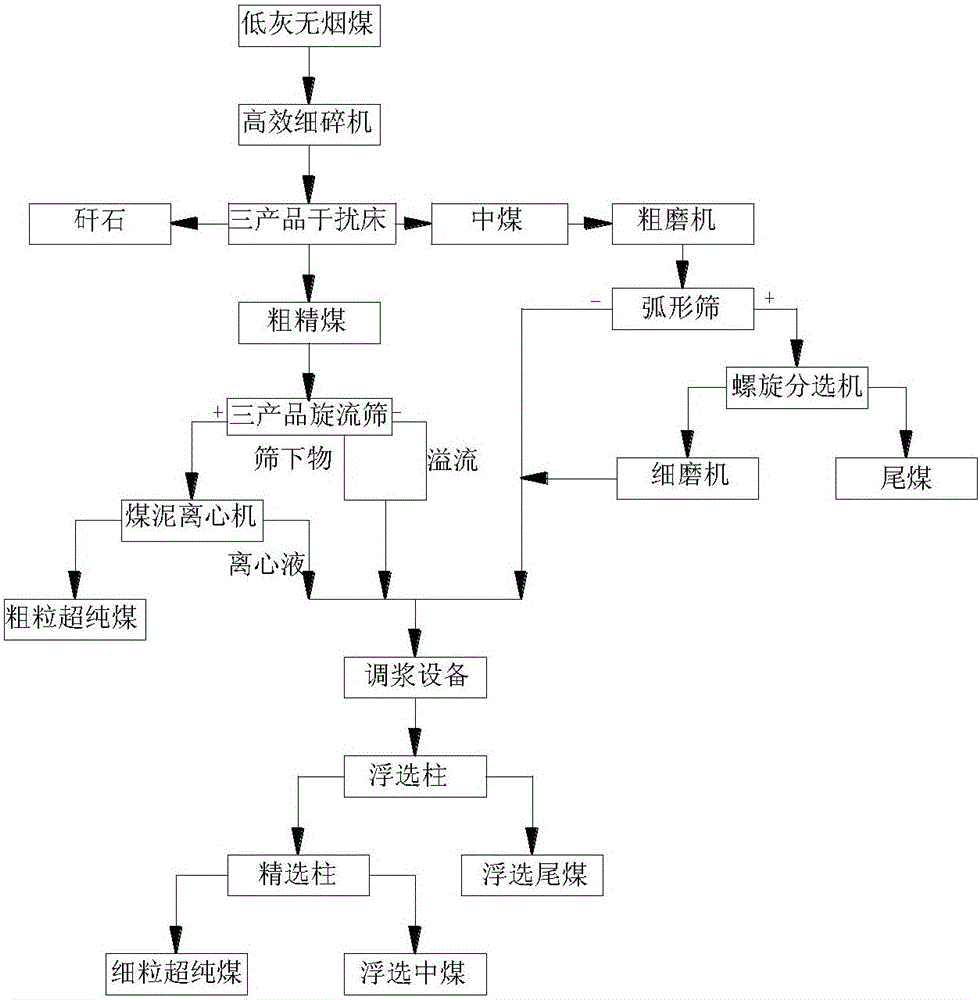

[0018] Such as figure 1 Shown: a. Crushing -50mm massive low-ash anthracite until the particle size is less than 3mm, the crushed material enters the three-product interference bed for sorting, and sorts to obtain coarse clean coal and medium coal, and rejects gangue products;

[0019] b. The coarse and clean coal obtained by sorting is fed into the three-product cyclone screen for classification respectively, and the medium coal product is fed into the coarse grinder for grinding;

[0020] c. After the coarse clean coal is classified by the three-product cyclone screen, the coarse clean coal retained on the screen is fed into the coal slime centrifuge for dehydration to become a coarse ultra-pure coal product, and the three-product cyclone screen undersieve and The overflow and the centrifugal liquid of the coal slime centrifuge are fed into the flotation slurry mixing equipment;

[0021] d. Feed the medium coal ground by the coarse grinder into a 0.15mm curved sieve for cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com