Mineral separator and use method thereof

A separator and mineral technology, which is used in the separation of high-density and low-density mixtures, mineral separators, the separation of difficult-to-separate materials with high-density mineral content and high-temperature materials, and can solve the problem of difficulty in improving production capacity and material handling. problems such as low speed and short sorting time, to achieve the effect of improving material utilization, improving accuracy and efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

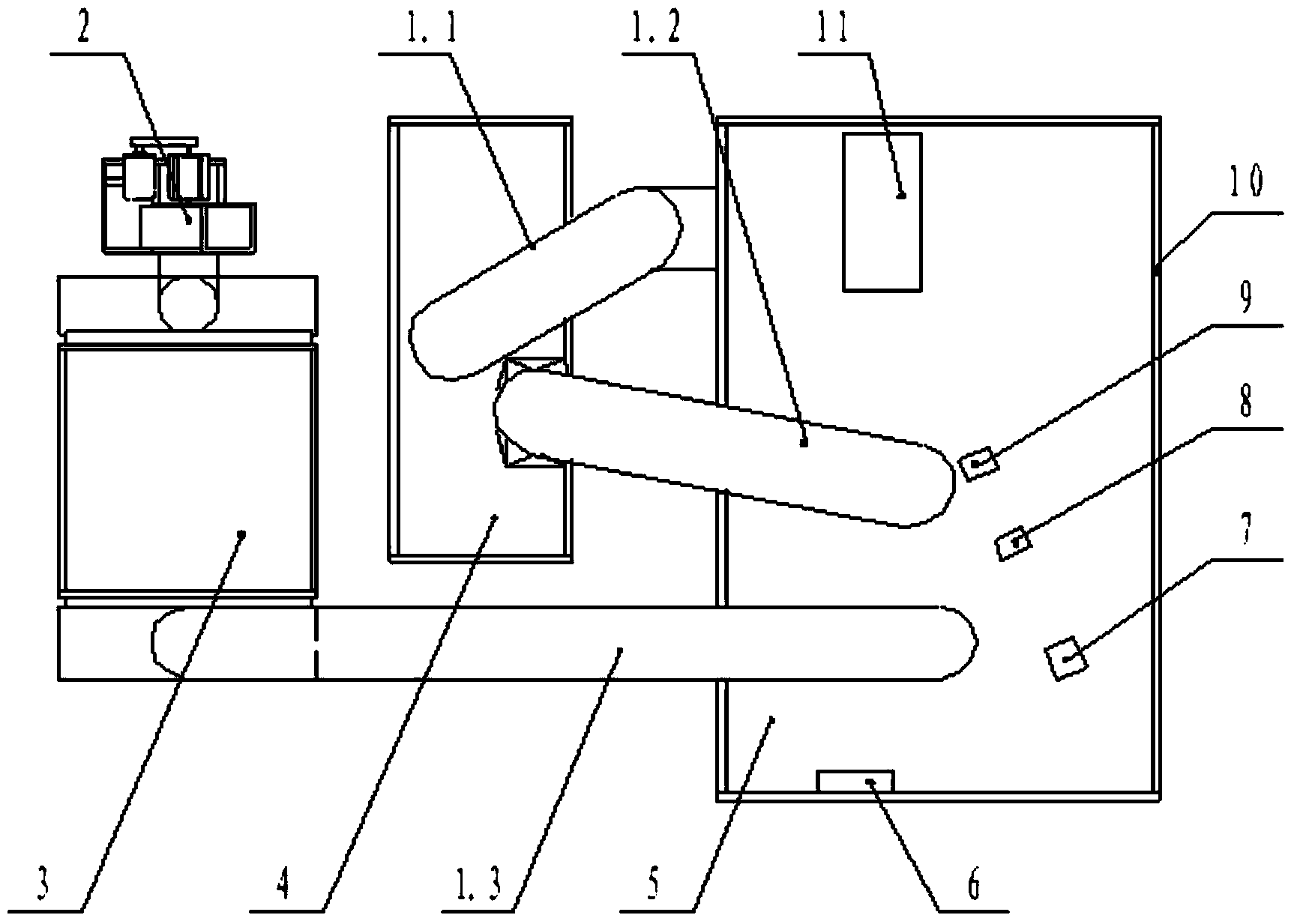

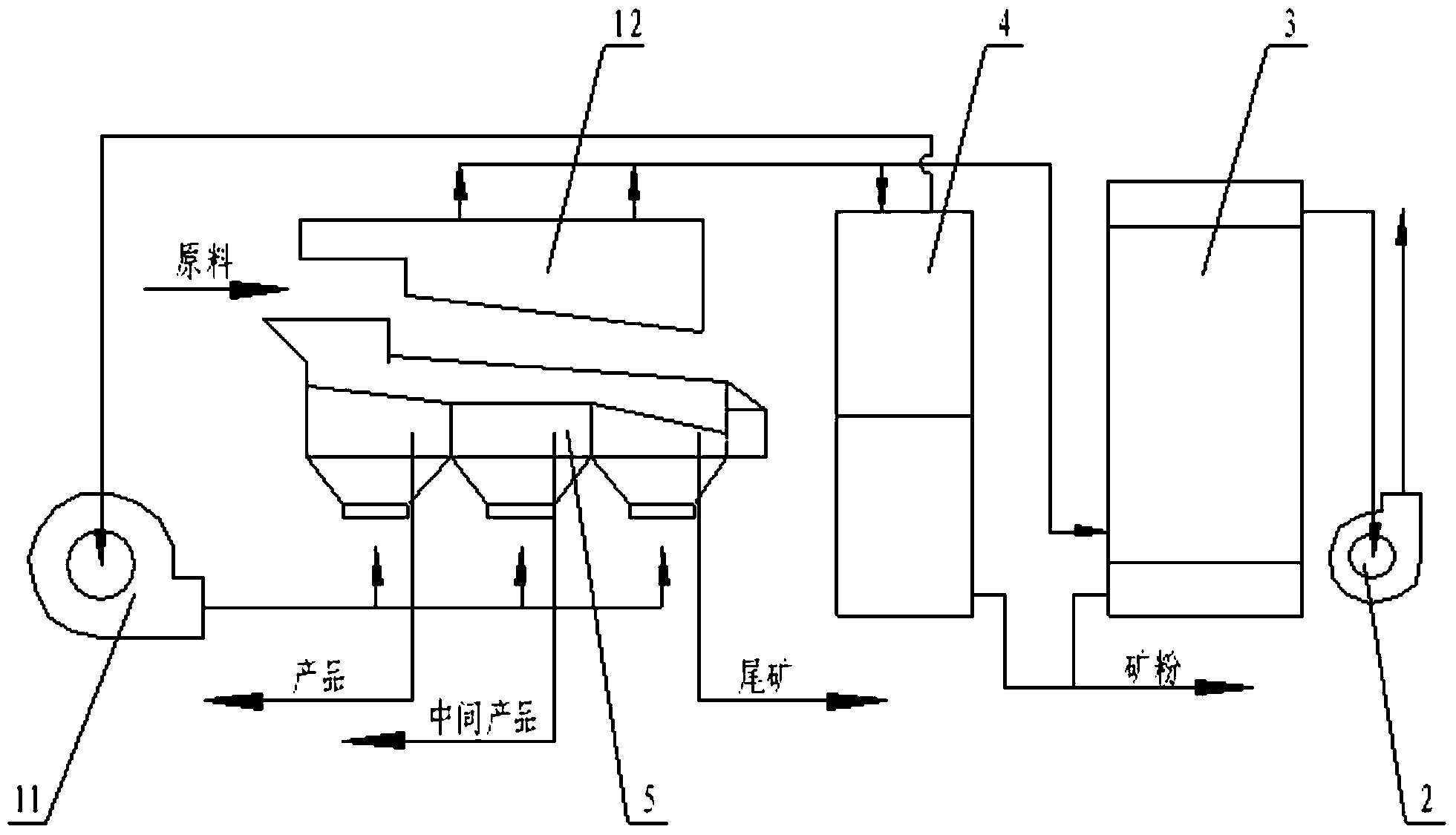

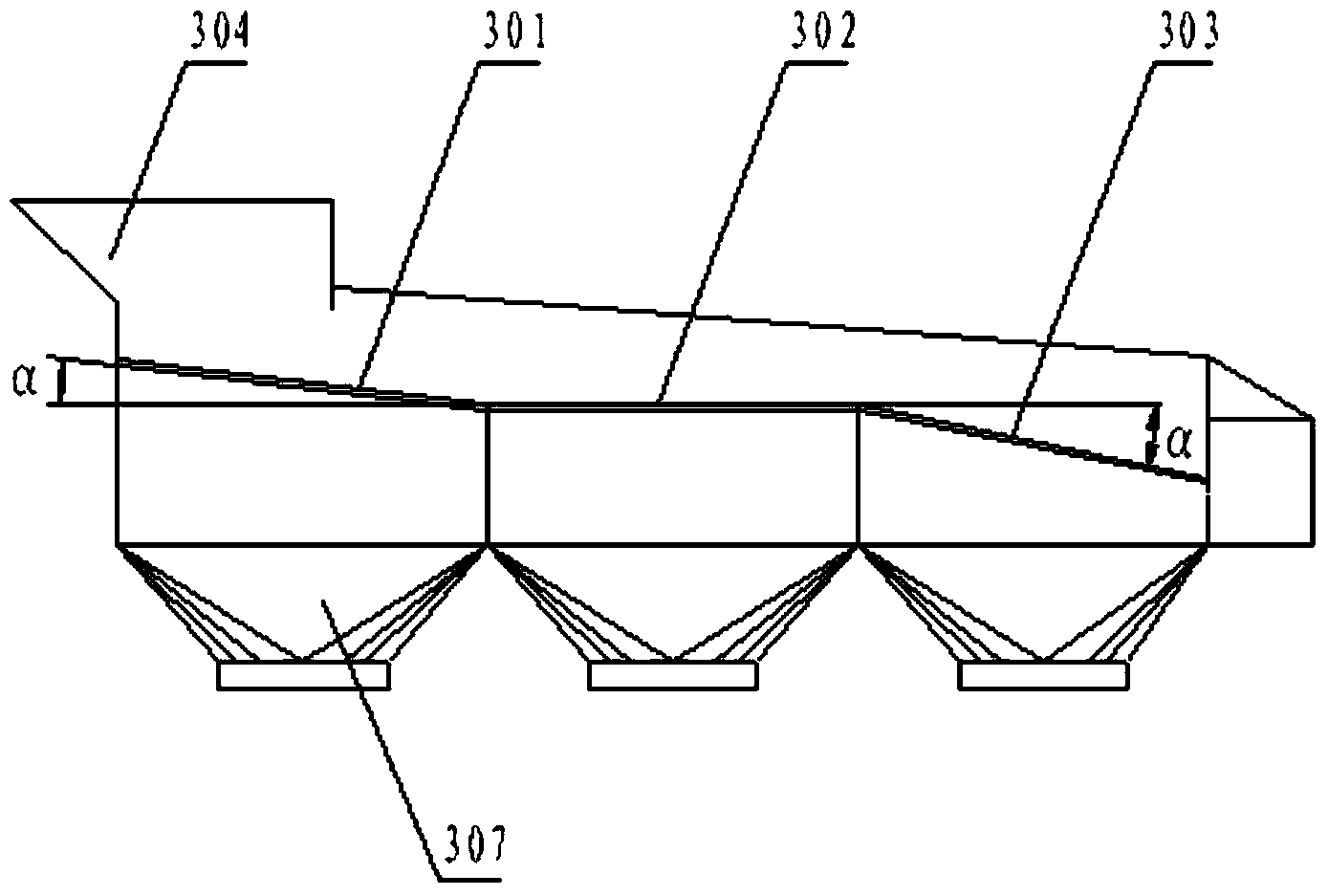

[0084] Embodiment one : see figure 1 , figure 2 , Fig. 3, which shows a separation bed 5 of a separation bed mineral separator according to the present invention. The material in the buffer bin is fed to the belt conveyor evenly by the vibrating feeder, and the belt conveyor feeds the material to the separation bed 5 of the mineral separator through the 304 feeding chute. The separation bed 5 is placed on an incline. The angle α between the longitudinal direction of the bed surface and the horizontal plane is -3°~+10°, the bed surface is divided into three sections, the angles of each section are not completely the same, and the angle β between the transverse direction of each section of the bed surface and the horizontal plane is -5°~15° ;, it is characterized in that the included angle of the feeding side of the bed surface changes with the change of mineral density, and the included angle of the 301 section is generally 3°~8°; the included angle of the 303 section bed s...

Embodiment 2

[0090] Embodiment two : When the particle size of the mineral is small, such as Figure 7 As shown in the bed surface, the bed surface is composed of a wear-resistant and temperature-resistant non-metallic rubber layer on the upper layer and a solidified metal layer on the lower layer. In the three areas of the bed surface 1a, 2b, and 3c, there are holes on the bed surface that penetrate the upper and lower layers with a certain perforation rate, which can be a uniform aperture, or the aperture can be divided into two specifications from the back plate to the discharge end. The large-diameter aperture is near the discharge end, and the small-diameter aperture is near the back plate. This makes the wind speed passing through the bed surface 7 more uniform, and the separation accuracy for small-sized materials is higher. The separator using the bed surface can overcome the defects of the prior art, has a reasonable pore size distribution, and has the ability to efficiently sep...

Embodiment 3

[0091] Embodiment Three : The main body of the separator is linked by the suspension system driven by the electric hoist. When the density of the separated minerals increases and fluctuates, it is necessary to adjust the angle β between the horizontal direction and the horizontal surface of the separation bed at any time. The combination can realize online automatic control. Improve the accuracy and efficiency of mineral separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com