Coal-based gasoline auxiliary agent

A technology of gasoline and additives, applied in the field of new energy, to achieve the effect of low cost, flexible mixing ratio and saving gasoline consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

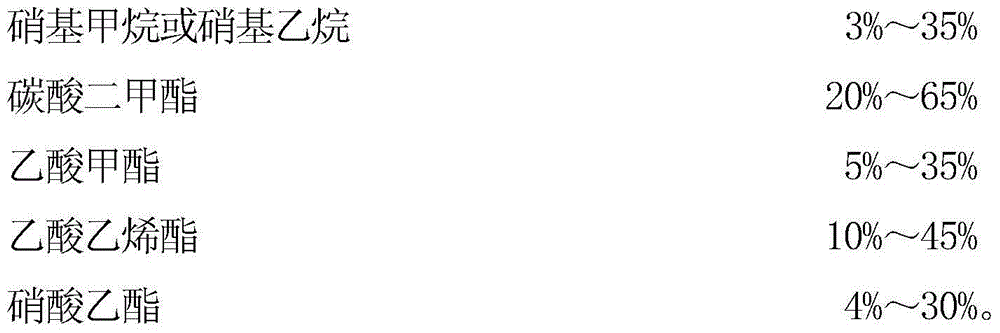

[0022] Taking the preparation of 100kg of coal-based gasoline additive as an example, the composition of the raw materials used is as follows:

[0023]

[0024] The preparation method is as follows: uniformly mixing nitroethane, dimethyl carbonate, methyl acetate, vinyl acetate and ethyl nitrate according to the mass ratio of the above raw materials to prepare a coal-based gasoline additive.

Embodiment 2

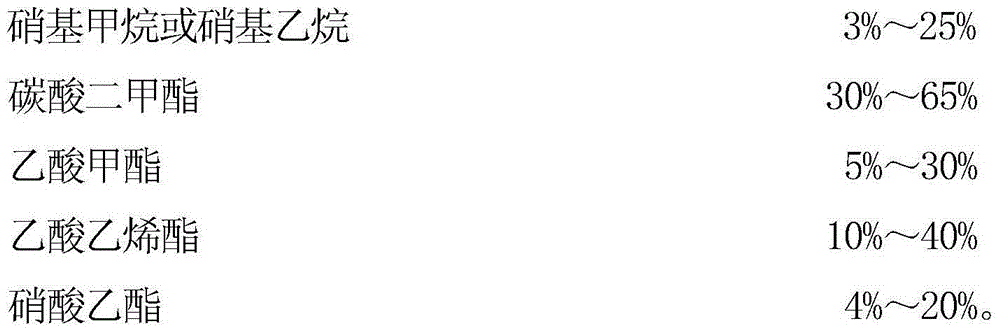

[0026] Taking the preparation of 100kg of coal-based gasoline additive as an example, the composition of the raw materials used is as follows:

[0027]

[0028] Its preparation method is identical with embodiment 1.

Embodiment 3

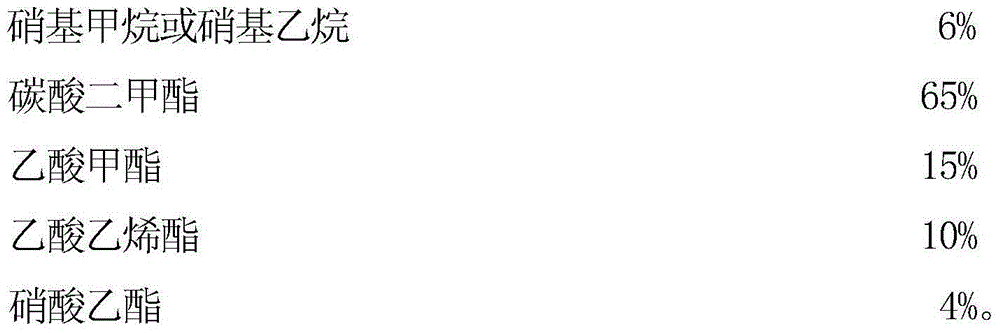

[0030] Taking the preparation of 100kg of coal-based gasoline additive as an example, the composition of the raw materials used is as follows:

[0031]

[0032]

[0033] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com