Coke and oxygen carrier particle separation device and method

A technology for particle separation and oxygen carrier, which is used in solid separation, cyclone devices, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

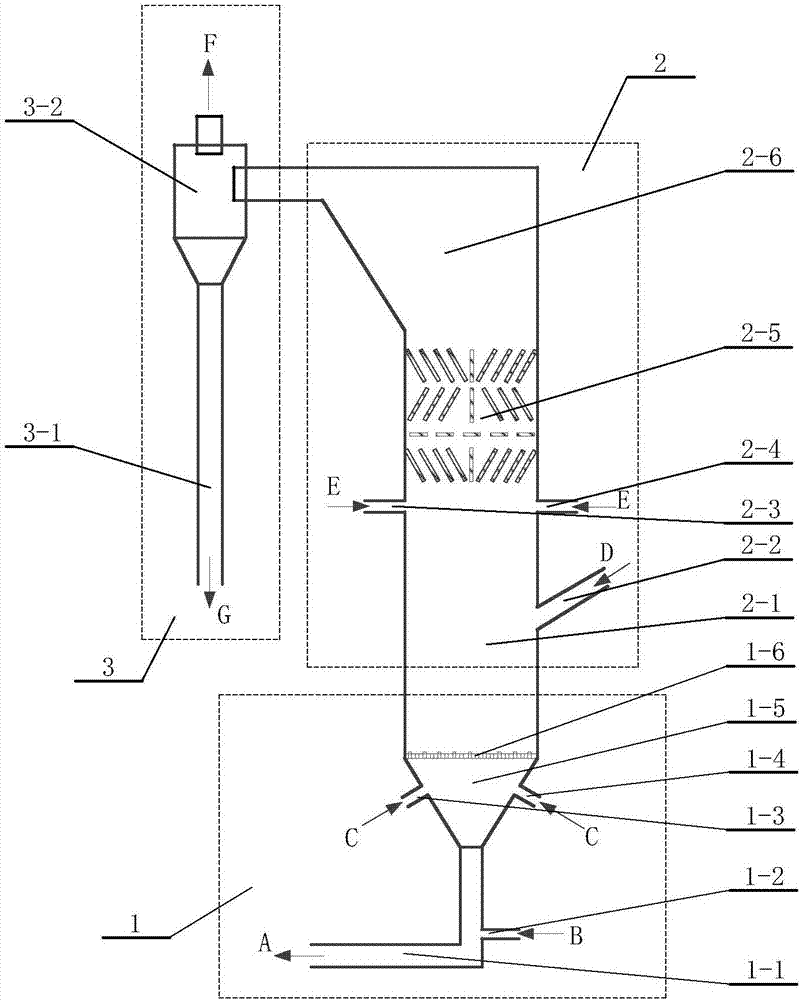

[0021] The coal char-oxygen carrier particle separation device of the present invention is composed of an oxygen carrier recovery area 1 , a disturbance separation area 2 and a coal char recovery area 3 . Oxygen carrier recovery area 1 includes oxygen carrier recovery pipe 1-1, loose air guide groove 1-2, first fluidization wind guide groove 1-3, fluidization wind second air guide groove 1-4, flow Bed transition section 1-5 and air distribution plate 1-6. The oxygen carrier recovery pipe 1-1 is connected to the fluidized bed free space 2-1 through the fluidized bed transition section 1-5, the air distribution plate 1-6 is arranged at the upper end of the fluidized bed transition section 1-5, and the fluidized air The first air guiding groove 1-3 and the second fluidizing air guiding groove 1-4 are respectively arranged on the left and right sides of the fluidized bed transition section 1-5, and the loose air guiding groove 1-2 is arranged in the oxygen carrier recovery pipe O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com