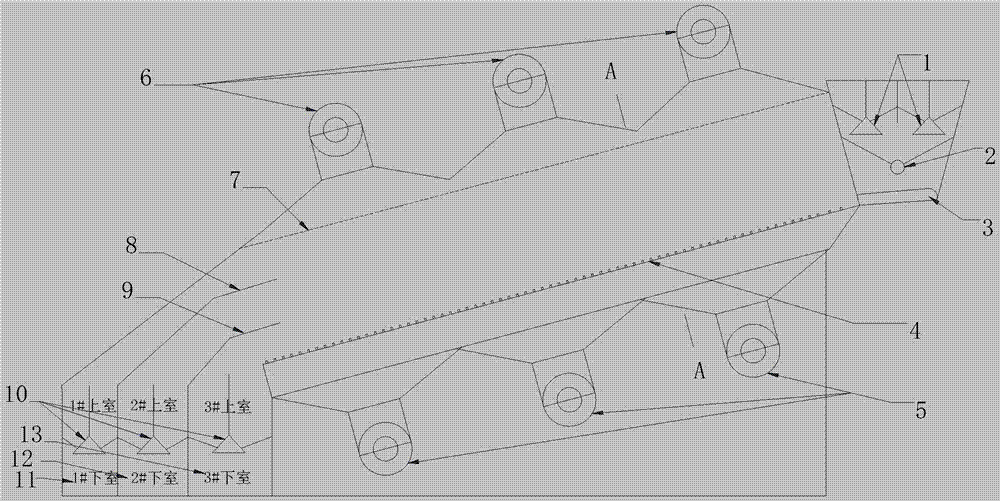

Auto-medium gas-solid two-phase fluidized bed dry coal separator based on bed layer partition plates

A technology of fluidized bed and coal preparation machine, which is applied in the direction of chemical instruments and methods, solid separation, wind shaker, etc. It can solve the problems of unstable separation accuracy of dry coal preparation and difficulty in realizing industrial application, and achieve low cost The effect of low cost, novel equipment and long service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

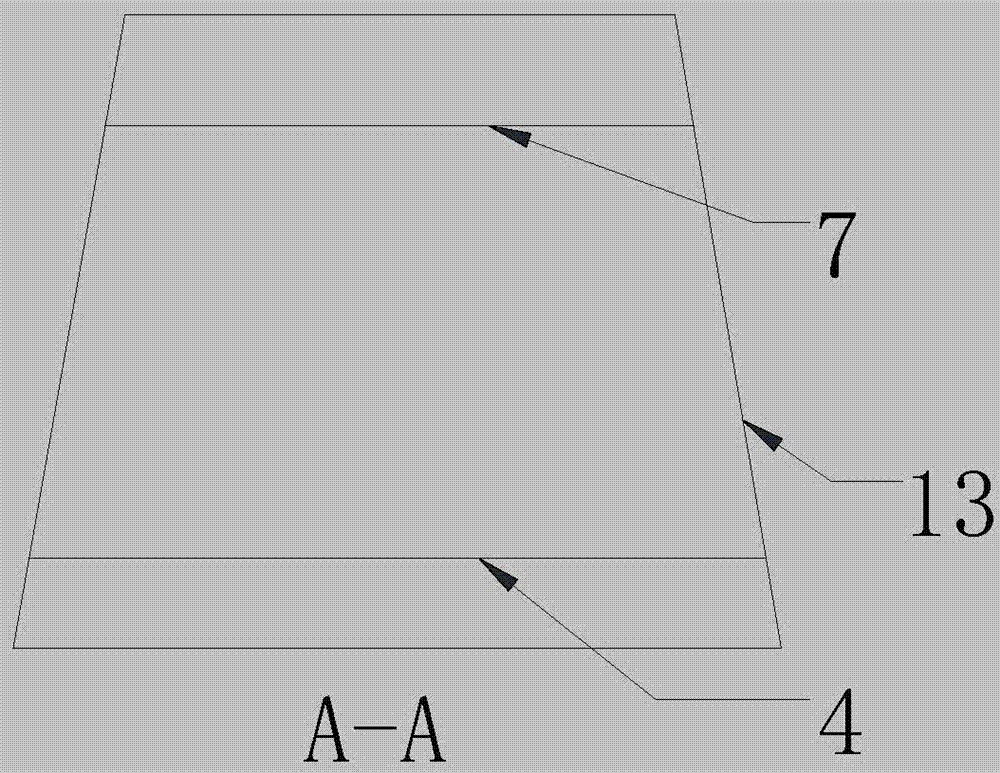

[0044] In this example, the length of the self-medium gas-solid fluidized bed is 9000mm, the diameter is 2500mm, the air blower is 2.2KW, and the wind pressure is 1.8MPa. There are 3 sets, the induced draft fan is 1.5KW, and the wind pressure is 1.5MPa. The angle is 65°. Send the raw coal crushed to less than 50mm into the feeding hopper by the belt conveyor, and then turn on the blower and the induced draft fan respectively to make the air flow field in the fluidized bed uniform and stable. Then turn on the operation switches of the feeder, cloth roller, vibrating feeder and feeder in turn. As shown in the schematic diagram, the two feeders work alternately to continuously feed the raw coal from the upper hopper to the middle hopper. Driven by the rotation of the distributing roller, the raw coal in the middle hopper is evenly spread to the vibrating feeder of the lower hopper. Driven by the vibrating feeder, the raw coal enters the fluidized bed at a certain flow rate.

[...

Embodiment 2

[0049] In this example, the self-medium gas-solid fluidized bed has a length of 12000mm, a diameter of 2500mm, four blowers of 2.2KW and a wind pressure of 1.8MPa, four induced draft fans of 1.5KW and a wind pressure of 1.5MPa, and the horizontal angle of the fluidized bed is 70°. Send the raw coal crushed to less than 50mm into the feeding hopper by the belt conveyor, and then turn on the blower and the induced draft fan respectively to make the air flow field in the fluidized bed uniform and stable. Then turn on the operation switches of the feeder, cloth roller, vibrating feeder and feeder in turn. As shown in the schematic diagram, the two feeders work alternately to continuously feed the raw coal from the upper hopper to the middle hopper. Driven by the rotation of the distributing roller, the raw coal in the middle hopper is evenly spread to the vibrating feeder of the lower hopper. Driven by the vibrating feeder, the raw coal enters the fluidized bed at a certain flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com