A visual sorting system applied to pineapple collection

A sorting system and sorting technology, applied in the field of visual sorting system for pineapple collection, can solve the problems of reduced pineapple collection efficiency, increased transportation cost, pineapple sorting, etc., and achieve the goal of reducing transportation cost, improving efficiency, and improving precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

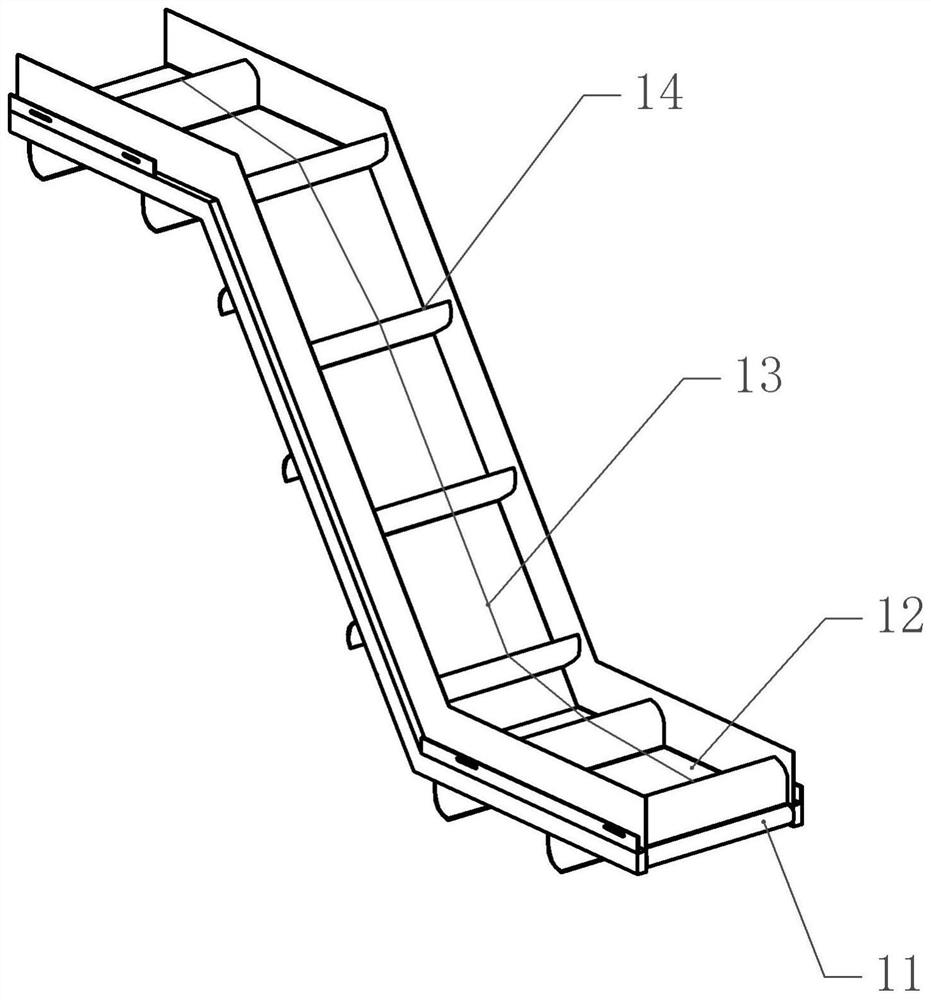

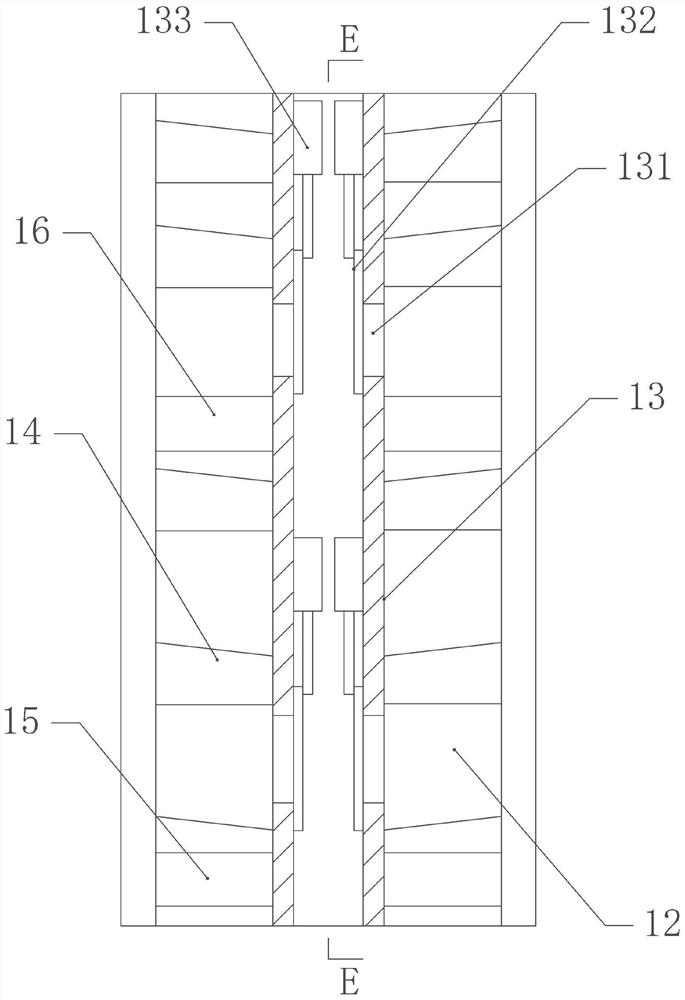

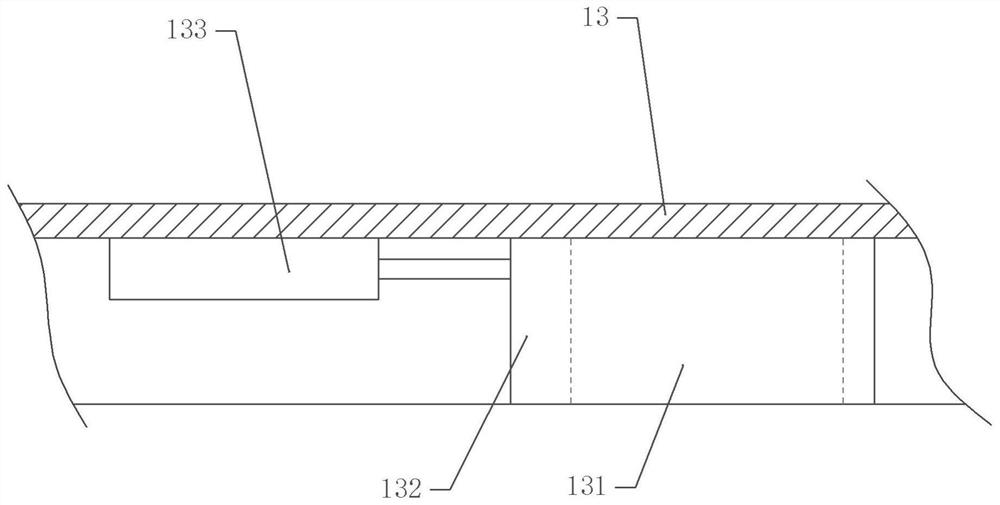

[0029] basically as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 and attached Figure 5 As shown, a visual sorting system applied to pineapple collection includes a Z-shaped right-angled lifting bracket 11, the lifting bracket 11 is bolted and connected with a sorting empty pipe 13, and both ends of the sorting empty pipe 13 are open to lift Existing conveyor belts 12 are installed on both sides of the bracket 11, and several inclined lifting baffles 14 are fixed with bolts on the belt of the conveyor belt 12. The conveyor belt 12 is driven by a hydraulic motor, and the hydraulic motor is equipped with a solenoid valve. One side of the pipe 13 is bolted and connected with a side baffle, and the end of the lifting baffle 14 close to the side baffle is higher than the end away from the side baffle. In this embodiment, the solenoid valve is used to adjust the rotational speed of the hydraulic motor, and then the transmission speed of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com