Magnetic separation method for gathering rich nickel and cobalt from chloridized and separated low-grade laterite

A laterite ore, low-grade technology, used in chemical instruments and methods, magnetic separation, solid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

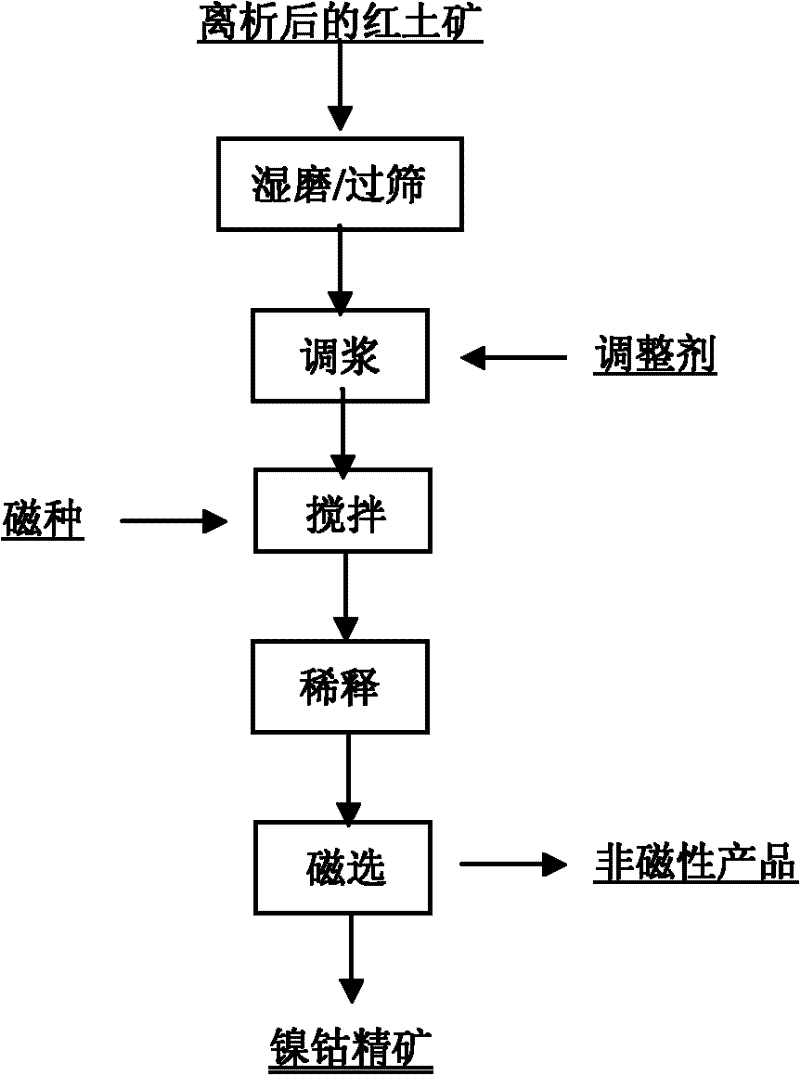

Method used

Image

Examples

Embodiment 1

[0021] A. 500kg of segregated laterite ore is wet-milled, its grade: Ni 1.45%, Co 0.05, Fe 11%, Ca 12.3%, Mg 13.2%. Then pass through a 300-mesh sieve, put it into a mixing tank after sieving, and add water to the amount that the mass percentage concentration of the slurry that needs to be reached is 50%.

[0022] B. Add sodium hydroxide solution to the prepared slurry solution to adjust the pH value of the solution to 6, and add 20 g of sodium hexametaphosphate.

[0023] C. Put 1 kg of magnetite (particle size < 1 micron) into the mixing bucket, and stir continuously for 5 minutes, and the rotating speed of the mixing bucket is 800rpm.

[0024] D. Put the stirred slurry into the magnetic separator with a mortar pump. The magnetic separator is a permanent magnetic roller strong magnetic separator with a surface magnetic field strength of 0.23T. Control the flow rate of the feed pipe and the water inlet pipe so that the slurry entering the magnetic separator is diluted to 10%....

Embodiment 2

[0027] A. 500kg of segregated laterite ore is wet-milled, its grade: Ni 1.30%, Co 0.08, Fe 20.11%, Ca 14.50%, Mg 10.2%. Then pass through a 300-mesh sieve, put it into a mixing tank after sieving, and add water in an amount of 50% of the slurry mass percentage concentration that needs to be achieved.

[0028] B. Add sodium hydroxide solution to adjust the slurry solution to adjust the pH value of the solution to 7, and add 25 g of sodium hexametaphosphate.

[0029] C. Put 1 kg of magnetite (particle size < 1 micron) into the mixing bucket, and keep stirring for 5 minutes. The rotating speed of the mixing bucket is 700rpm.

[0030] D. Pump the stirred slurry onto the magnetic separator with a mortar pump. The magnetic separator is a permanent magnetic roller strong magnetic separator with a surface magnetic field strength of 0.24T. Control the flow rate of the feed pipe and the water inlet pipe so that the slurry entering the magnetic separator is diluted to 15%.

[0031] Thr...

Embodiment 3

[0033] A. 500kg of segregated laterite ore is wet-milled, its grade: Ni 1.35%, Co 0.14, Fe 11.20%, Ca 10.50%, Mg 6.32%. Then pass through a 300-mesh sieve, put it into a mixing tank after sieving, and add water in an amount of 50% of the slurry mass percentage concentration that needs to be achieved.

[0034] B. Add sodium hydroxide solution to the prepared slurry solution to adjust the pH value of the solution to 7.5, and add 30 g of sodium hexametaphosphate.

[0035] C. Put 1 kg of magnetite (particle size < 1 micron) into the mixing bucket, stir continuously for 3 minutes, and the rotating speed of the mixing bucket is 800rpm.

[0036] D. Put the stirred slurry on the magnetic separator with a mortar pump, and the magnetic separator is a permanent magnetic roller strong magnetic separator with a surface magnetic field strength of 0.23T. Control the flow rate of the feed pipe and the water inlet pipe so that the slurry entering the magnetic separator is diluted to 10%.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com