Process for processing complex gold ore containing copper and arsenic

A complex and gold mine technology, applied in the improvement of process efficiency, wind shaker, flotation and other directions, can solve the problems of easy consumption of sodium cyanide, low leaching rate, etc., and achieve good economic benefits, high technical indicators, process equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A complex gold ore containing copper and arsenic is mainly composed of useful minerals such as chalcopyrite, gold and arsenopyrite. Gangue minerals are mainly quartz, feldspar and clay minerals, etc., some of which are oxidized on the surface of arsenopyrite. Gold exists in arsenopyrite, chalcopyrite and gangue.

[0030] The copper content in the ore is 1.2%, the arsenic content is 2.87%, and the gold content is 10g / t (both are percentages by weight).

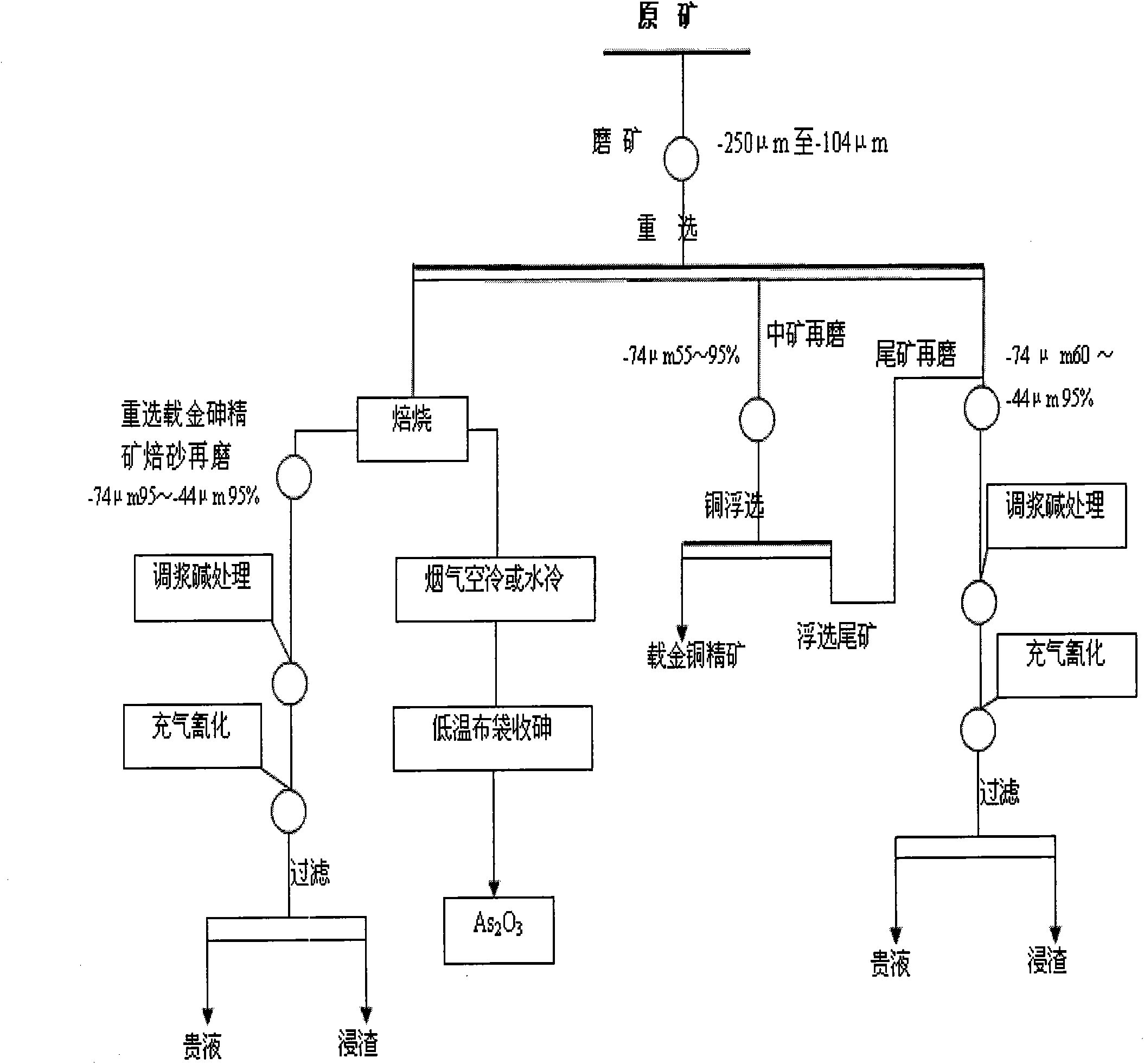

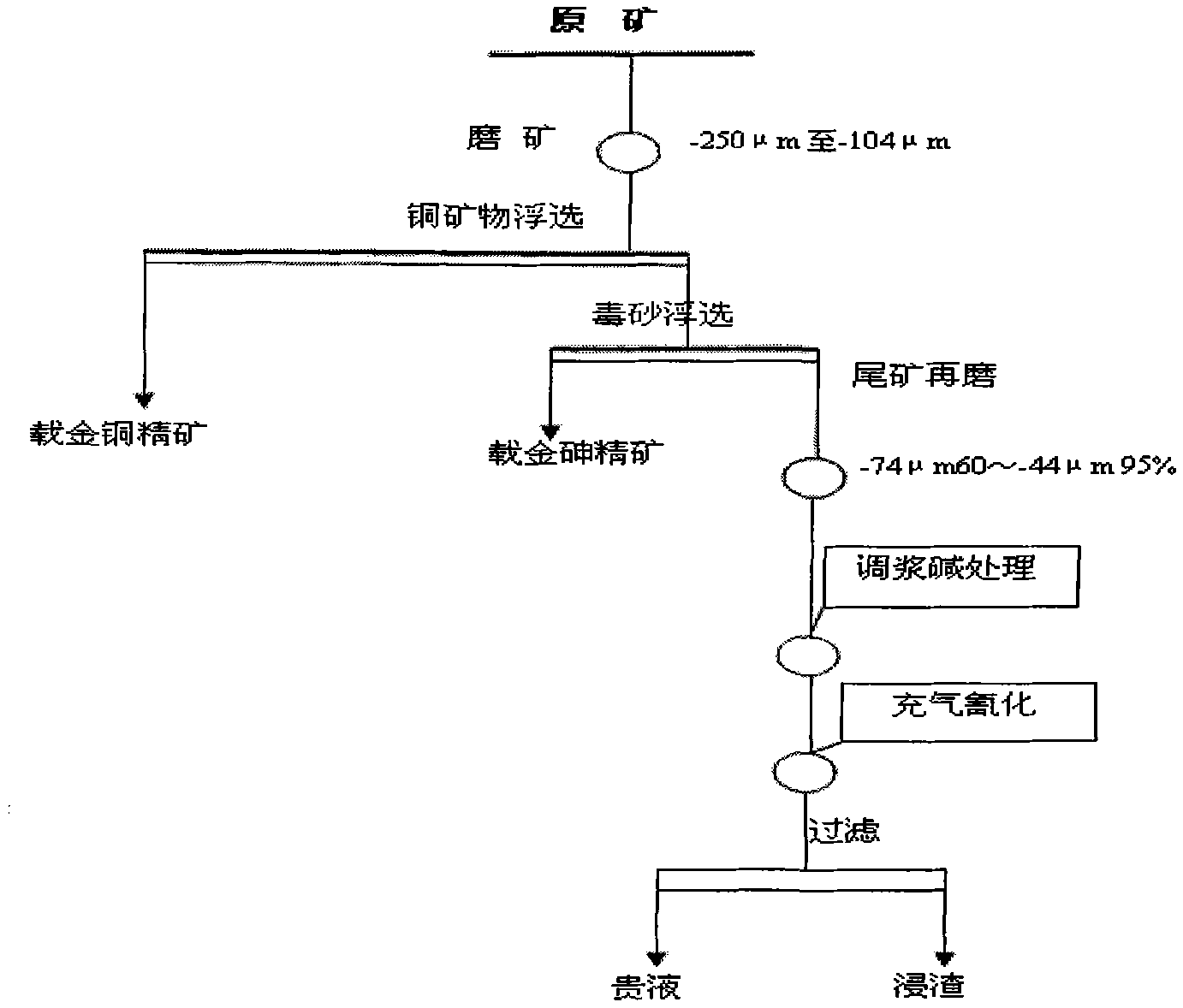

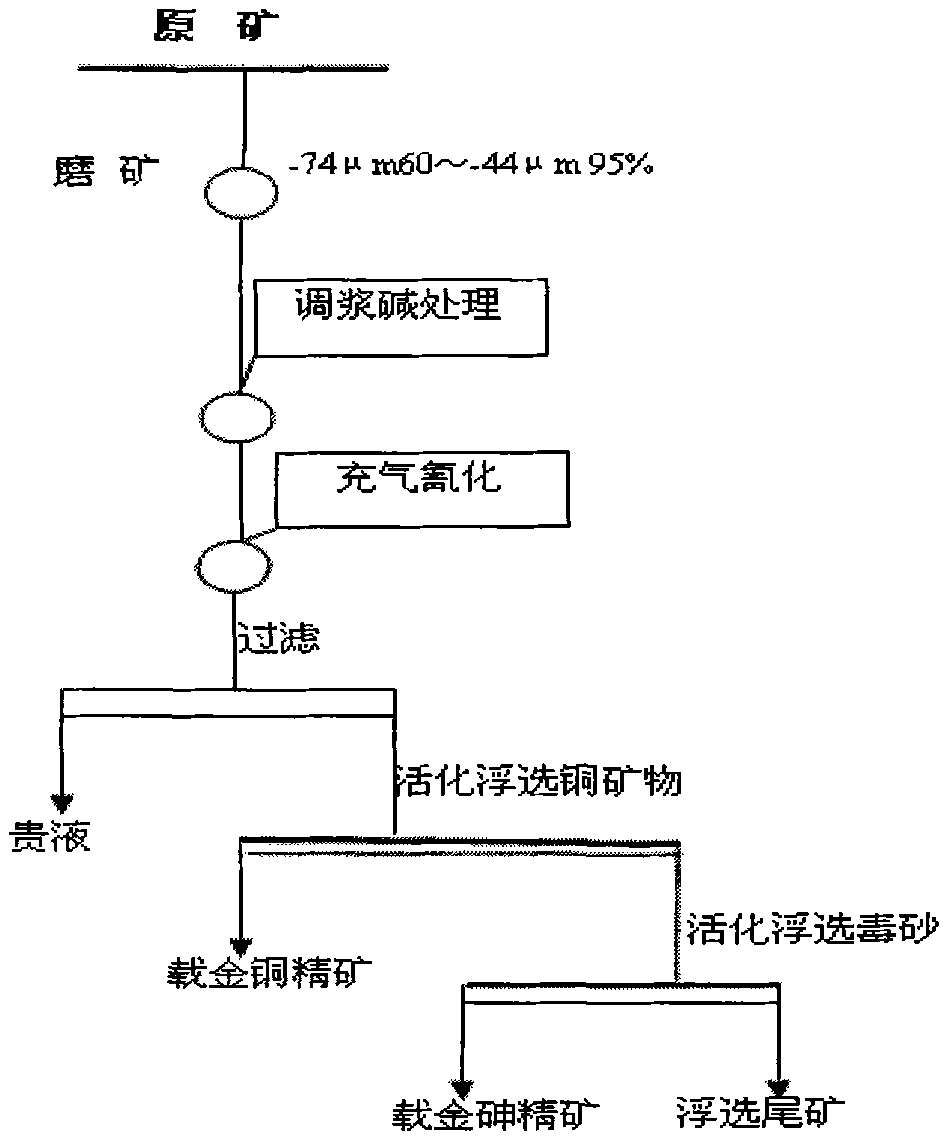

[0031] Using the method of the present invention, the raw ore is ground to -150 μm, and the shaker gravity separation enriches the arsenopyrite. The roasting temperature of the gravity separation concentrate is 750° C., the temperature for collecting arsenic in a low-temperature cloth bag is 120° C., and the leaching particle size of the calcined sand is -44 μm60 %, the liquid-solid ratio is 1.5:1, add protected soda lime 4kg / t, after the pH is stabilized above 11.5, add sodium cyanide 5kg / t, leaching for 72h; Flotatio...

Embodiment 2

[0035] Ore source is with embodiment 1.

[0036] Using the method of the present invention, the raw ore is ground to -120 μm for shaking table gravity separation to enrich the arsenopyrite-loaded arsenic. The roasting temperature of the gravity separation concentrate is 700° C., the temperature for collecting arsenic in a low-temperature cloth bag is 100° C., and the calcine leaching particle size is - 74μm90%, the liquid-solid ratio is 2:1, add protected soda lime 4kg / t, after the pH is stabilized above 11.5, add sodium cyanide 4kg / t, and leaching for 72h; - Isopropyl-N-ethylthiocarbamate and sodium diethylaminodithiocarbamate 1:1 flotation of chalcopyrite, flotation pulp concentration is 30%, the total dosage of chemicals is 70g / t, flotation The time is 16 minutes; Gravity separation tailings (-44μm 60%) are adjusted to a liquid-solid ratio of 2:1, 4kg / t of protected soda lime is added, and after the pH is stabilized to above 11.5, 1.5kg / t of sodium cyanide is added. Leach ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com