Separation and purification method for garnets of iron ore tailings and product of method

A sand garnet and purification method technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problem of low purity of garnet, achieve the effect of improving purity, improving recovery rate, and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

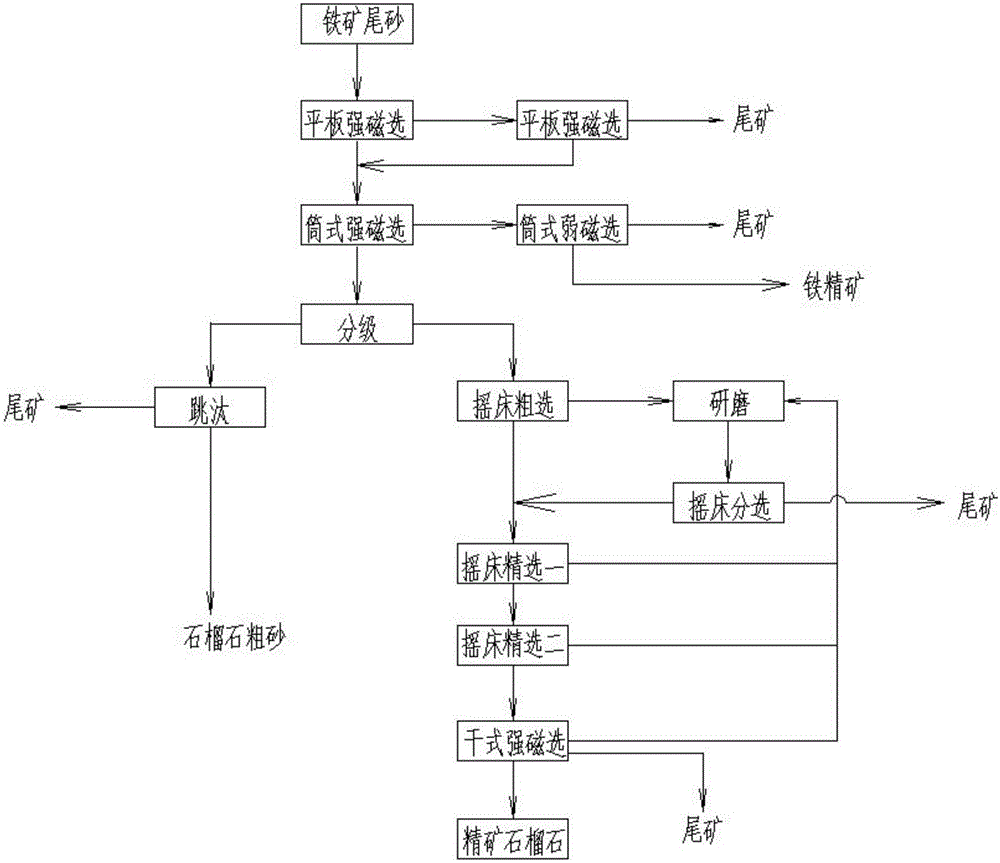

[0033] see figure 1 , the present embodiment provides a method for separating and purifying iron ore tailings garnet, comprising the following steps:

[0034] (1) Feed the iron ore tailings into a flat plate strong magnetic separator, and carry out tailing separation under a magnetic field strength of 1300mt to obtain magnetic minerals and non-magnetic minerals respectively;

[0035] (2) The magnetic minerals are passed into the drum type strong magnetic separator, and the strong magnetic minerals and the weak magnetic minerals are separated under the magnetic field strength of 350mt;

[0036] (3) Screening and classifying the weak magnetic minerals, sorting the classified weak magnetic minerals according to the size of the particles with a jig and a shaking table, and separating the garnet particles and silicate minerals with large density differences ;

[0037] (4) The garnet particles are subjected to dry-type strong magnetic separation to separate the concentrate garnet ...

Embodiment 2

[0044] The main difference between this embodiment and Embodiment 1 is that this embodiment provides a method for separating and purifying iron ore tailings garnet, comprising the following steps:

[0045] (1) Feed the iron ore tailings into a flat plate strong magnetic separator, and carry out tailing separation under a magnetic field strength of 1500mt to obtain magnetic minerals and non-magnetic minerals respectively;

[0046] (2) The magnetic minerals are passed into the drum type strong magnetic separator, and the strong magnetic minerals and the weak magnetic minerals are separated under the magnetic field strength of 400mt;

[0047] (3) Screening and classifying the weak magnetic minerals, sorting the classified weak magnetic minerals according to the size of the particles with a jig and a shaking table, and separating the garnet particles and silicate minerals with large density differences ;

[0048](4) The garnet particles are subjected to dry-type strong magnetic s...

Embodiment 3

[0055] The main difference between this embodiment and Embodiment 1 is that this embodiment provides a method for separating and purifying iron ore tailings garnet, comprising the following steps:

[0056] (1) Feed the iron ore tailings into a flat plate strong magnetic separator, and carry out tailing separation under a magnetic field strength of 1400mt to obtain magnetic minerals and non-magnetic minerals respectively;

[0057] (2) The magnetic minerals are passed into the drum type strong magnetic separator, and the strong magnetic minerals and the weak magnetic minerals are separated under the magnetic field strength of 380mt;

[0058] (3) Screening and classifying the weak magnetic minerals, sorting the classified weak magnetic minerals according to the size of the particles with a jig and a shaking table, and separating the garnet particles and silicate minerals with large density differences ;

[0059] (4) The garnet particles are subjected to dry-type strong magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com