Multistage combined type dry method coal dressing system and method

A combined dry method and coal preparation technology, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of incapable of large-scale production of product rate, low efficiency of dry separation technology, high moisture content, etc. Achieve the effects of sorting accuracy, improving sorting efficiency and output, and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

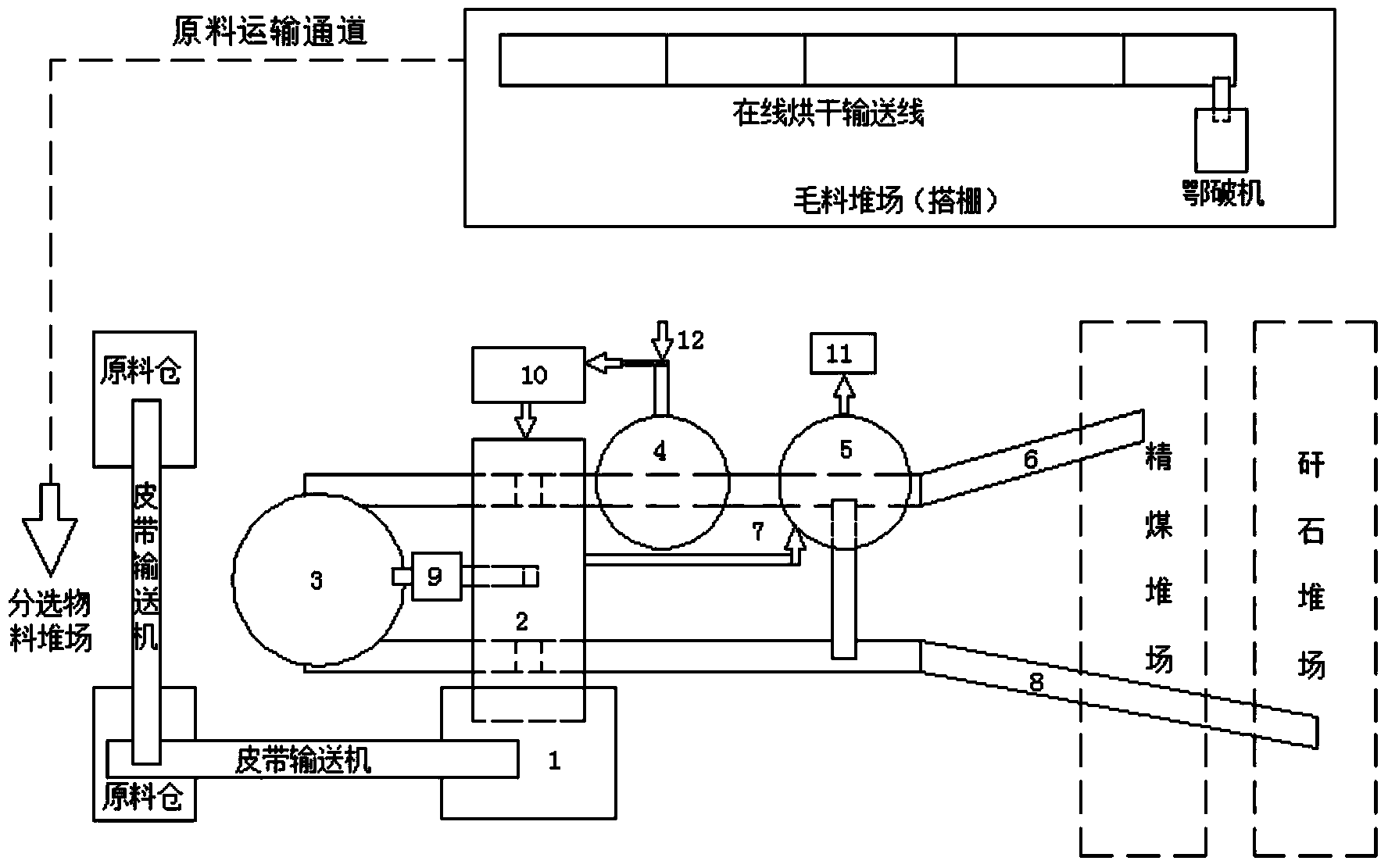

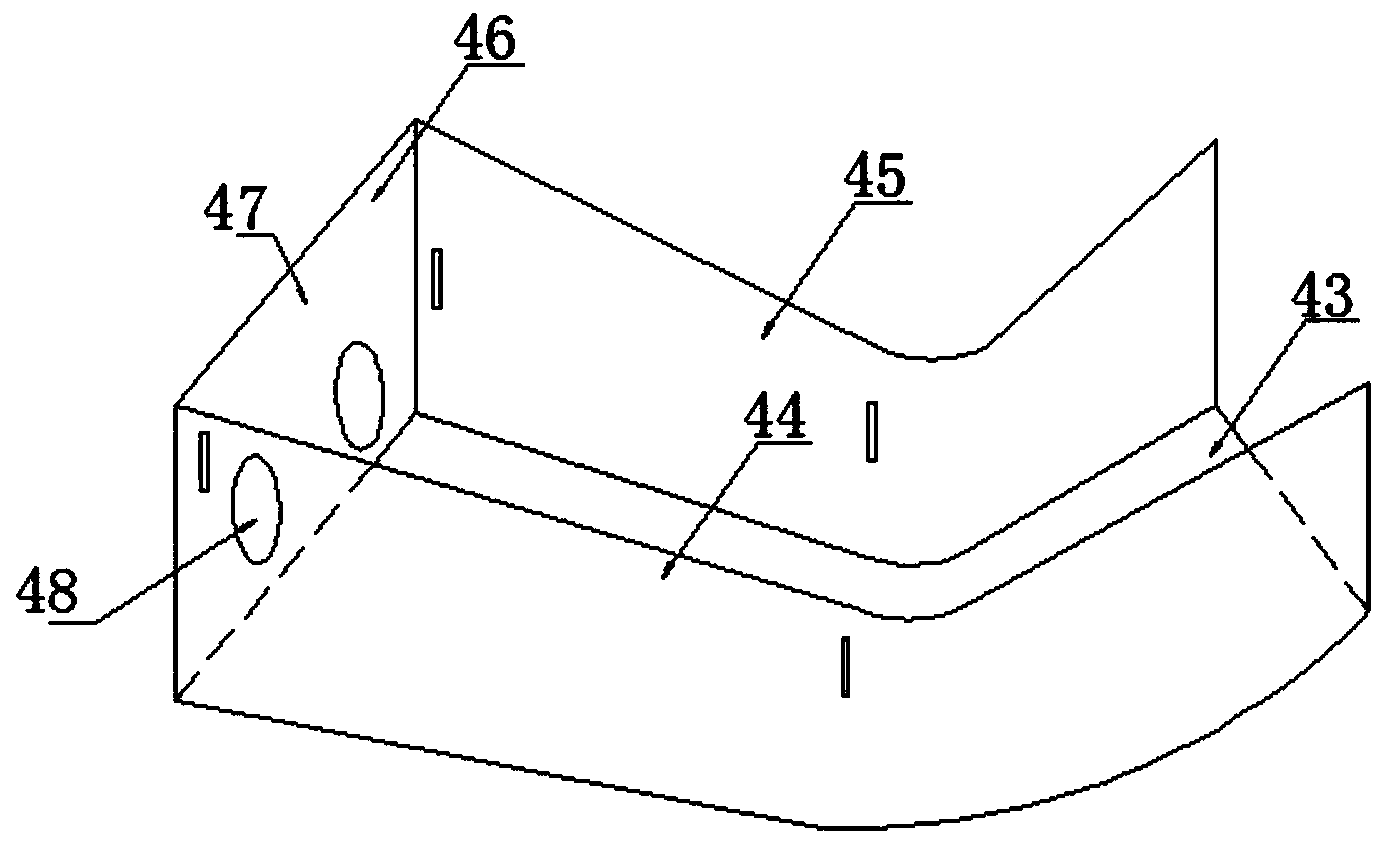

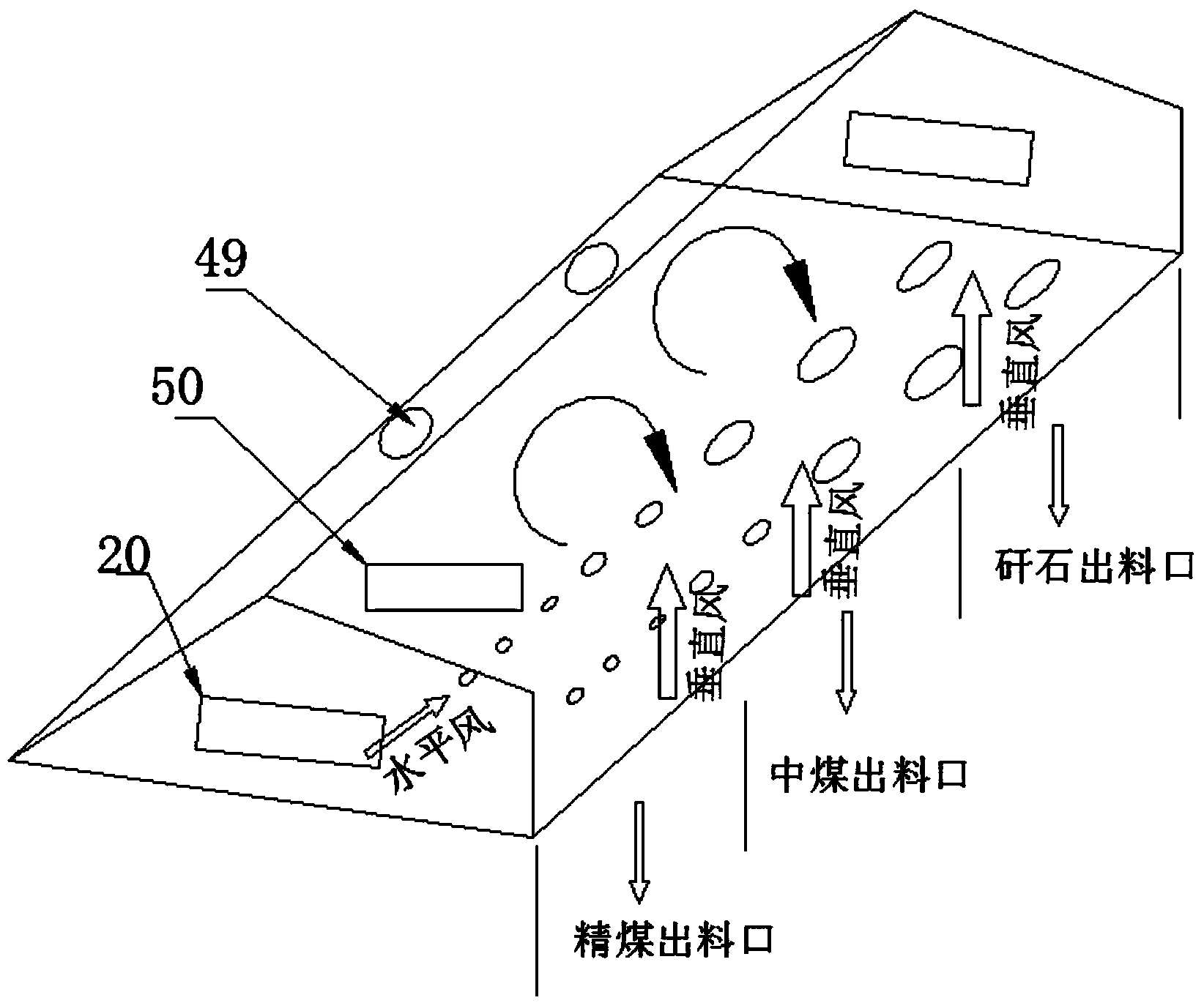

[0054] In order to overcome the disadvantages of low separation accuracy, low output (not large-scale production) and low product rate in the existing dry coal preparation technology, this embodiment provides a figure 1 The shown multi-stage composite dry coal separation system includes a frame, a composite dry horizontal sorter suspended on the frame 2, and a feed for the composite dry horizontal sorter 2 Coal scuttle 1, cyclone dust removal blast circulator 4, bag dust removal residual air drain 5, clean coal conveyor 6, fine ash waste transfer screw 7, gangue conveyor 8, separation main fan 10, dust collection system induced draft fan 11; through the vertical sorting bed feed hoist 9 is connected to the composite dry vertical sorter 3 under the medium coal discharge port of the composite dry horizontal sorter 2, wool stockyard (scaffolding), raw coal Crushing drying conveyor line, material storage yard to be selected, etc.

[0055] It is not difficult to see from the figure th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com