Sorting device for judging flaw quality of magnetic ring

A technology for sorting devices and magnetic rings, applied in sorting, solid separation, chemical instruments and methods, etc., can solve problems such as difficult targeted statistical verification of defective products, failure to detect defective products, etc., to achieve safety protection, Avoid the effects of violent collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

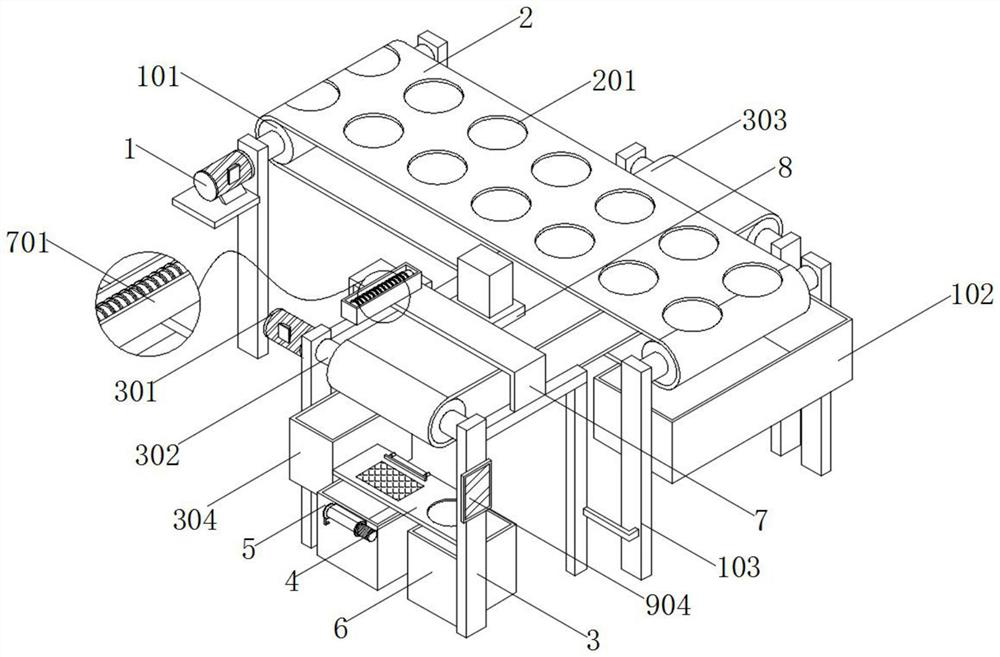

[0045] see figure 1 and Figure 4 , an embodiment provided by the present invention: a sorting device for judging the quality of magnetic ring scars, including a No. 2 support frame 3, a scar detection frame plate 7 is installed on the top of the No. No. 2 electromagnet 701 is installed on the top side of 7, a laser lamp group 703 is installed at the center of the bottom of the scar detection frame plate 7, and two groups of No. 1 photosensitive sensitive areas 702 symmetrically arranged are installed on the bottom of the scar detection frame plate 7 , and the two sets of No. 1 photosensitive areas 702 are respectively located in the middle of the laser lamp group 703, and the bottom of the flaw detection frame plate 7 is equipped with No. 2 photosensitive areas 704 arranged symmetrically, and the No. The area 702 is symmetrically arranged, and the second photosensitive area 704 is electrically connected to the second electromagnet 701;

[0046] Specifically, the laser lamp ...

Embodiment 2

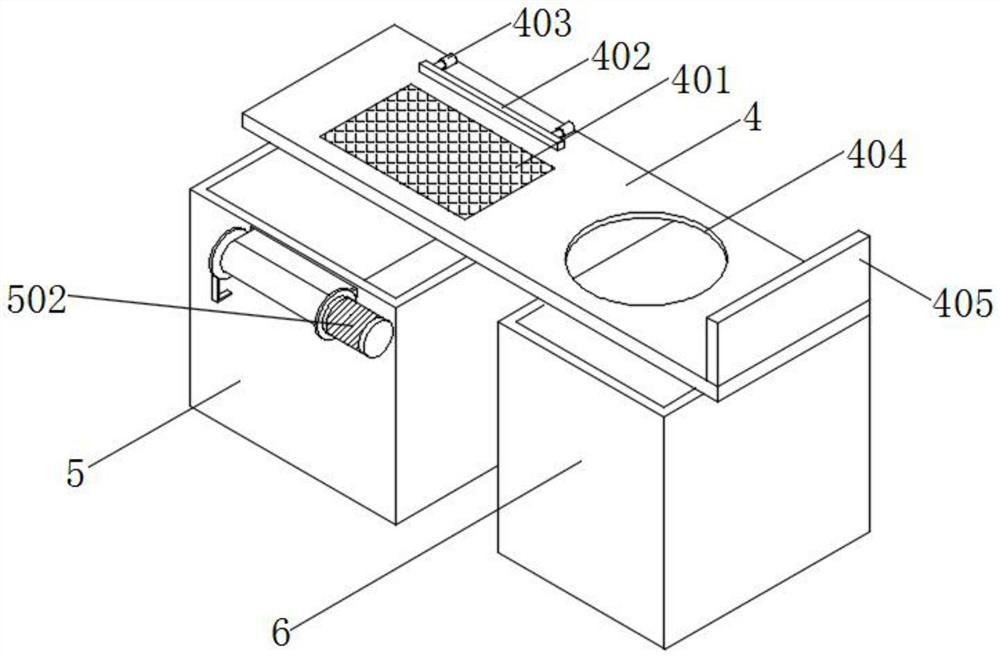

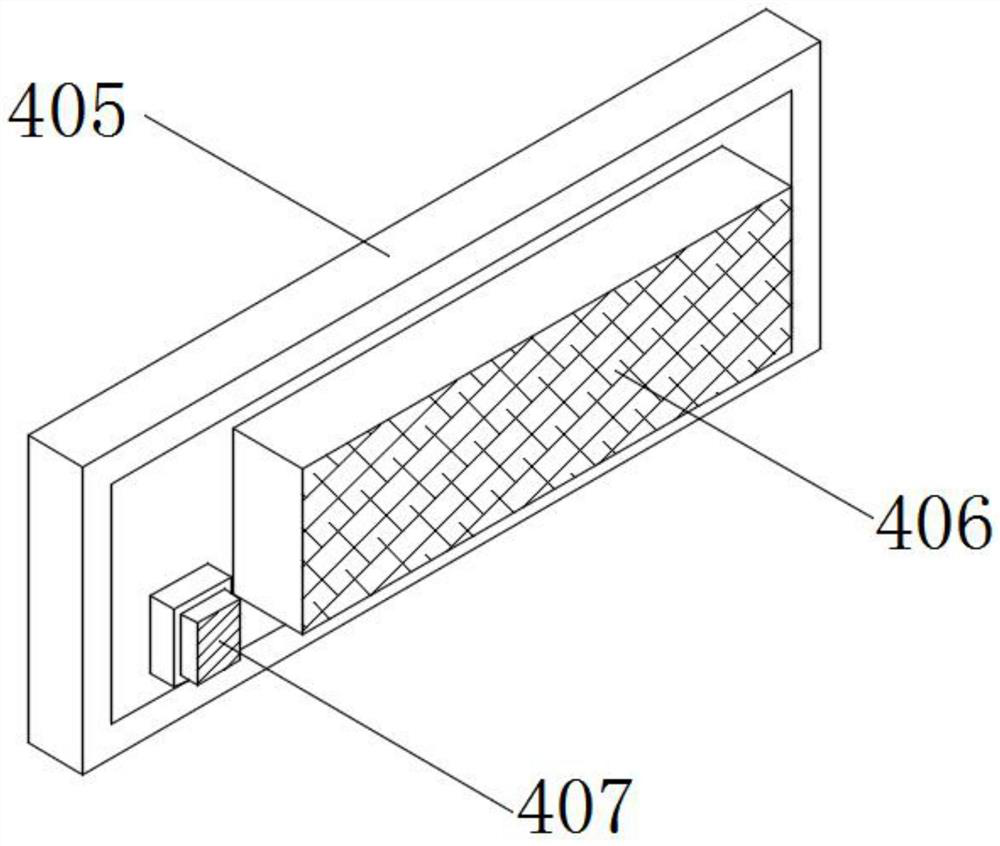

[0050] see Figure 1-Figure 3 , an embodiment provided by the present invention: a kind of sorting device for judging the quality of magnetic ring scars, including a picking plate 4, wherein one side surface of a group of No. Two sets of symmetrically arranged electric push rods 403 are installed on the top of the picker board 4. One end of the electric push rods 403 is connected to a strip-shaped push plate 402. A weighing plate 401 is installed on the top surface of the picking plate 4, and the weighing plate 401 is located In front of the plate 402, the inside of the picking plate 4 is provided with a through discharge hole 404, and the discharge hole 404 is located on one side of the weighing plate 401, and a vertical plate 405 is installed on the top of the picking plate 4, and the vertical plate 405 is located at the outlet. One side of material hole 404, one side surface of vertical plate 405 is equipped with No. 1 electromagnet 406 and infrared range finder 407, and in...

Embodiment 3

[0055] see Figure 5-Figure 7 , an embodiment provided by the present invention: a sorting device for judging the quality of magnetic ring scars, including a protective collecting frame 5, the bottom of the picking plate 4 is fitted with a protective collecting frame 5, the protective collecting frame The front of 5 is equipped with a servo motor 502 through a bracket, the output end of the servo motor 502 is connected with a film roll round rod 501, the surface of the film roll round rod 501 is connected with a foam roll 506, and the surface of the foam roll 506 is equipped with a coating film 504, The insides of the foam roll 506 and the covering film 504 are all provided with equidistantly arranged easy-tear seams 503, and the easy-tear seams 503 inside the foam roll 506 and the covering film 504 overlap up and down, and the top of the protective collecting frame 5 is equipped with a speed measuring meter 505, and the speed meter 505 is electrically connected to the servo m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com