A rotary lever type fruit unloading mechanism, fruit sorting device and control method

A technology of unloading mechanism and rotating lever, applied in the direction of program control, electrical program control, general control system, etc., can solve the problems of inaccurate grading movement direction, complex manufacturing process and high manufacturing cost, and achieve simple structure and space utilization. High efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

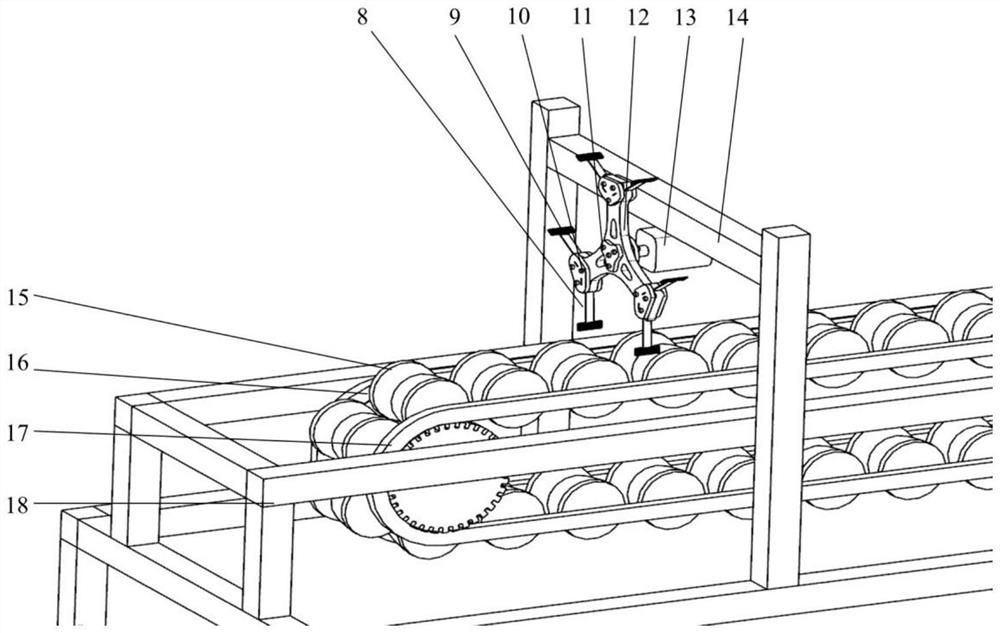

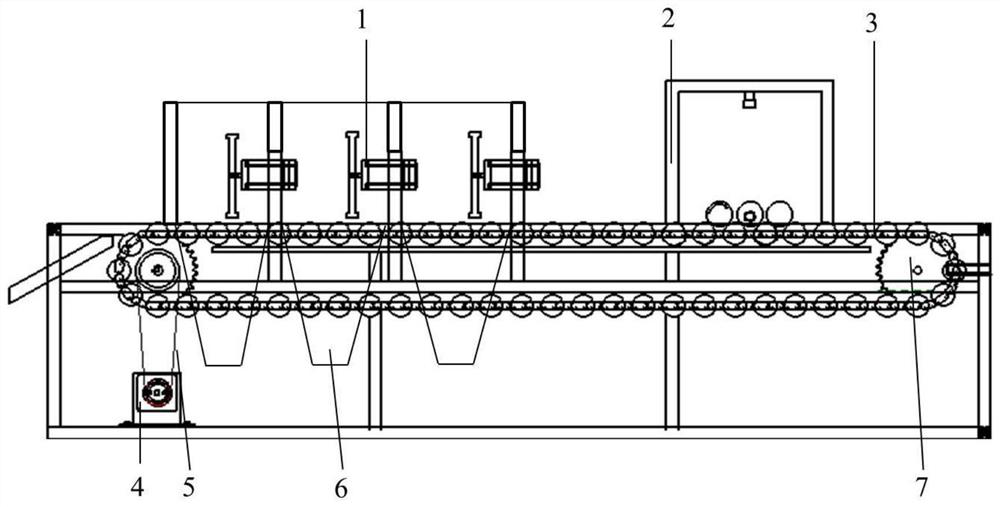

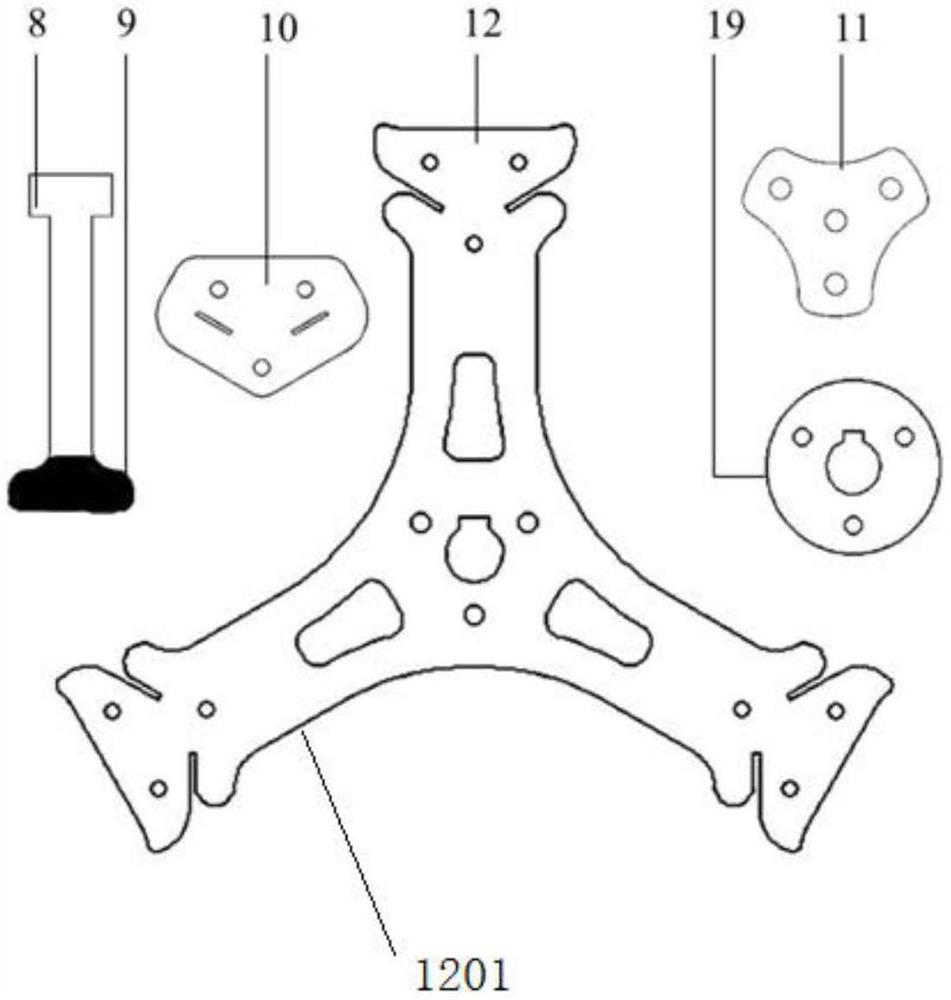

[0032] Such as figure 1 and image 3 As shown, the rotary lever type fruit unloading mechanism of the present invention comprises a stepper motor 13, a lever 12, a leaf spring 8, a fixed plate 10, a front auxiliary plate 11, and a rear auxiliary plate 12, and the lever 12 includes three The poles 1201, the tops of the three poles 1201 are connected to each other and distributed on the same horizontal plane, the angle between every two poles 1201 is 120°, and the connecting surface of two adjacent poles 1201 is an arc surface, Capable of holding a single fruit.

[0033] The centers of the driving rod 12 and the rear auxiliary board 19 are all provided with through holes, and the motor shaft of the motor 13 passes through the through holes in the center of the rear auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com