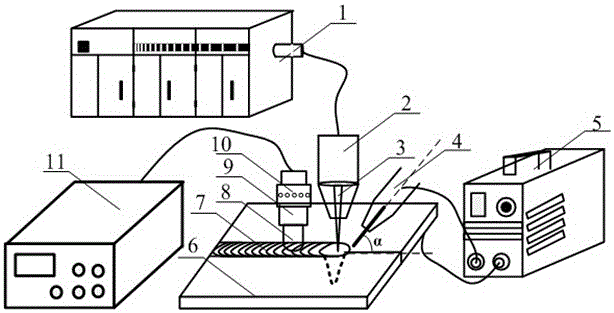

Ultrasonic assistec laser electric arc composite welding method of aluminum alloy

A laser arc and ultrasonic assisted technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large heat input of MIG arc, large number of pores in welded joints, large welding deformation, etc., to enhance joint strength and The effect of improving corrosion resistance, weld strength and corrosion resistance, and reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0024] Example 2, first, for the 5052 aluminum alloy plate with a size of 200×200×7, pretreatment is carried out according to the design method of the present invention, and then the 5052 aluminum alloy plate is placed on the auxiliary process equipment, and the 5052 aluminum alloy plate is clamped by using a tightening device. Clamping; then turn on the ultrasonic generator 11, TIG welding machine 5, and laser 1, and adjust the welding process parameters to the required parameters, wherein, the laser power P=4kW, the welding speed v=1.2m / min, the defocus amount △f =-2mm, the current is 140A, the shielding gas is argon, the shielding gas flow q=30L / min, the working frequency of the ultrasonic wave generated by the ultrasonic generator 11 is set to 50kHz, and the pressure of the vibrating head 8 against the weld 7 is maintained at 0.3MPa ; The angle between the tungsten pole and the surface of the seam to be welded is 60° in the TIG arc welding torch 4, the laser incidence direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com