Small-sized conditioner for testing

A small-scale test and conditioner technology, applied in application, feed, food science, etc., can solve the problems of clogging the feed inlet, easy to be corroded and invalid, reducing the service life of the conditioner spindle, etc., to achieve miniaturization, reduce Loss, improve the effect of conditioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

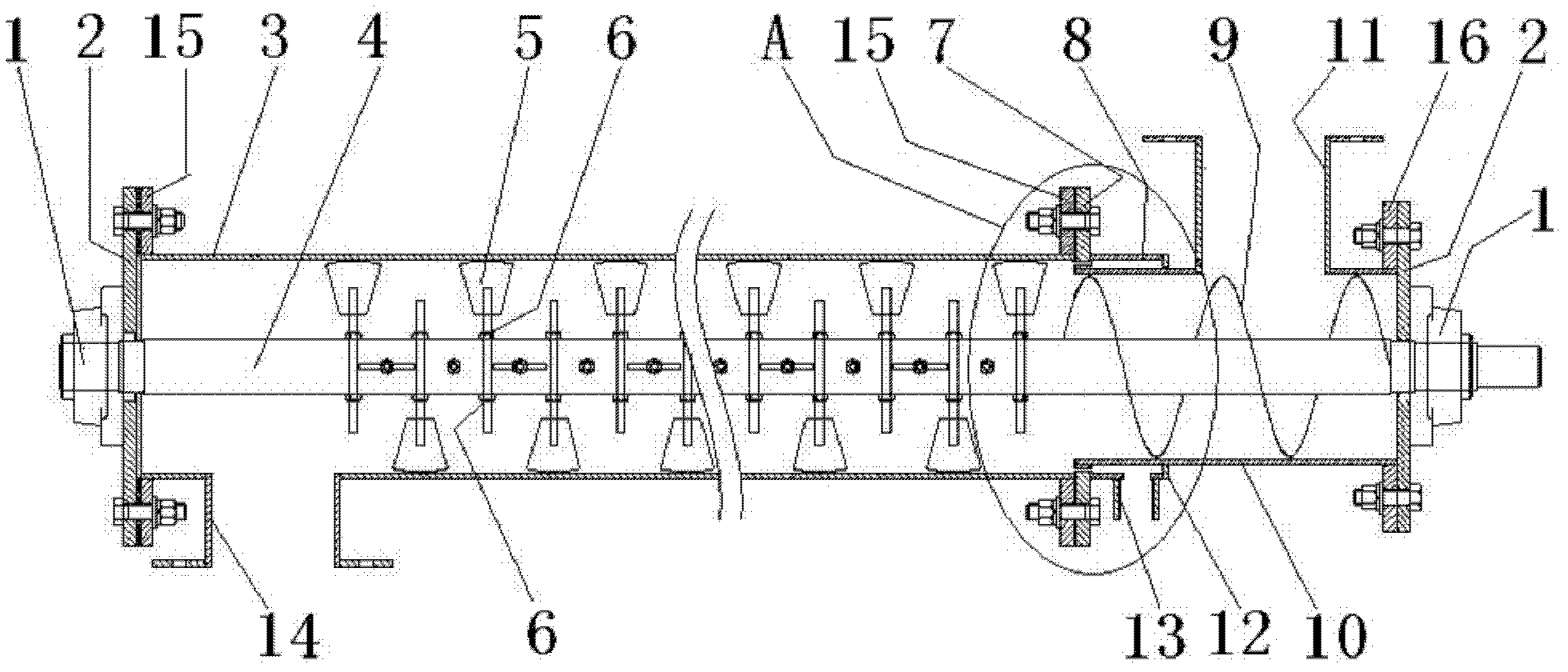

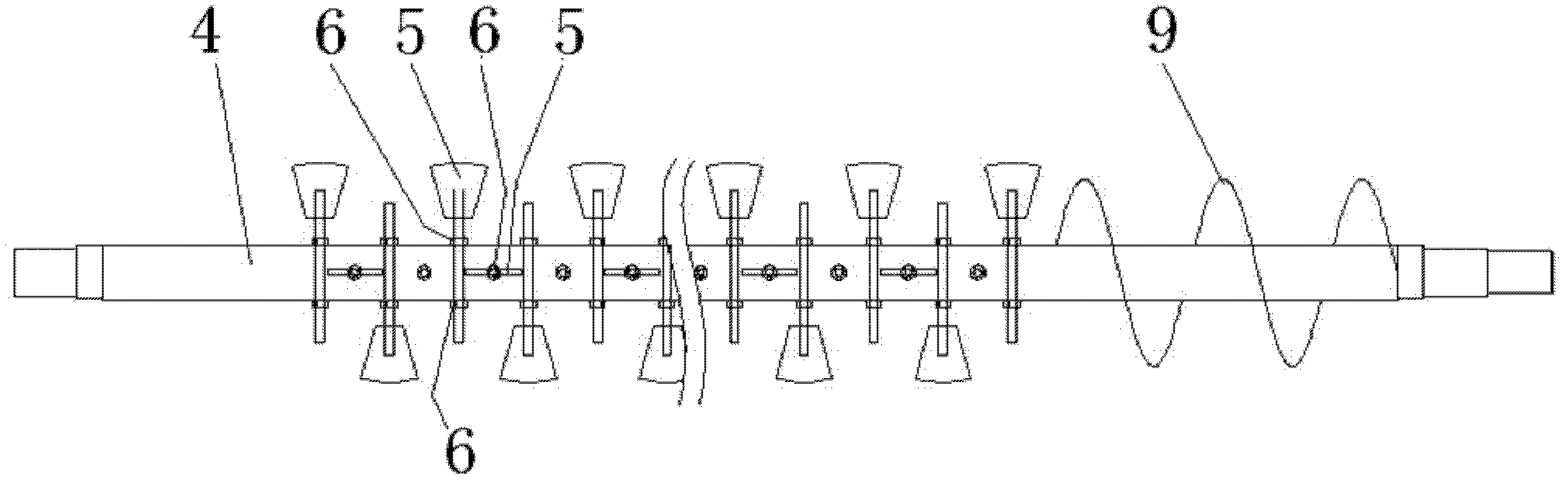

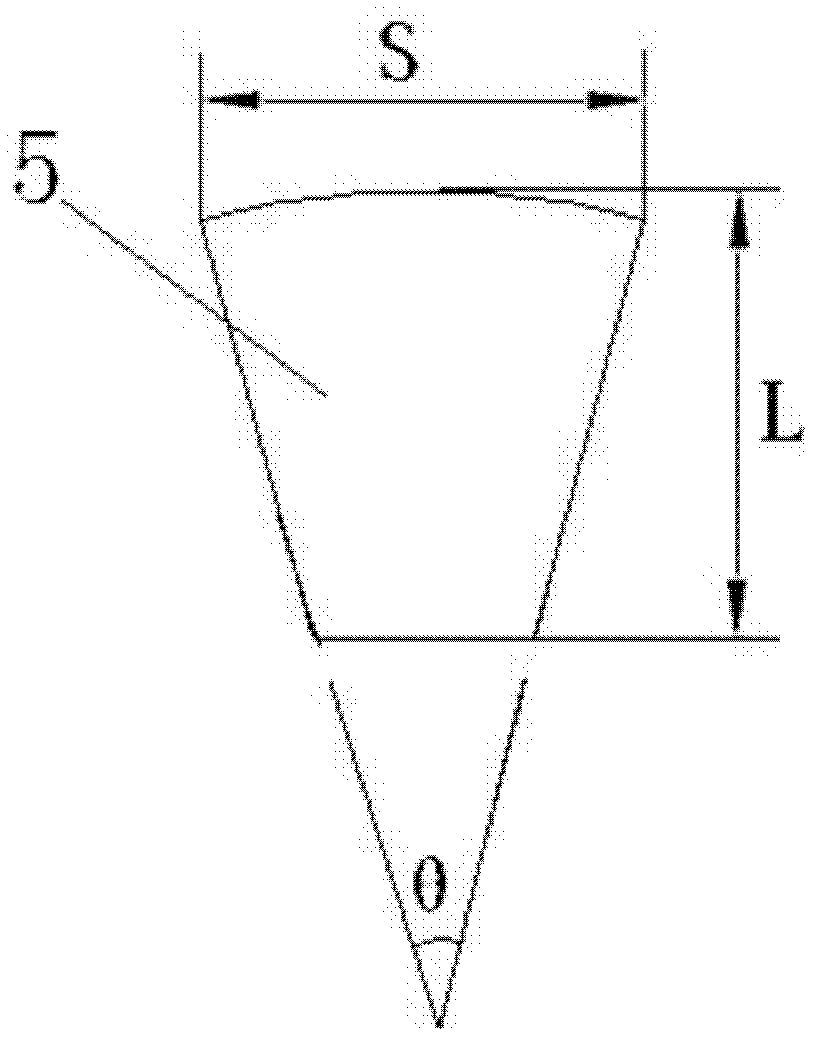

[0035] The schematic diagram of the general assembly of the embodiment of the conditioner for the small-scale test is as follows figure 1 As shown, the small test conditioner is composed of a conditioner shell and a conditioner rotor. The conditioner shell is divided into two parts: conditioning unit and feeding unit. In the tempering unit, the left and right ends of the cylindrical tempering chamber 3 are fixedly connected with a tempering chamber flange 15 respectively, and the discharge port 14 with the flange communicates with the tempering chamber 3 downward at the left end of the tempering chamber 3 And fixed connection, there is a central round hole on the blocking plate 2, a flange pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com