Patents

Literature

31results about How to "Improve conditioning efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

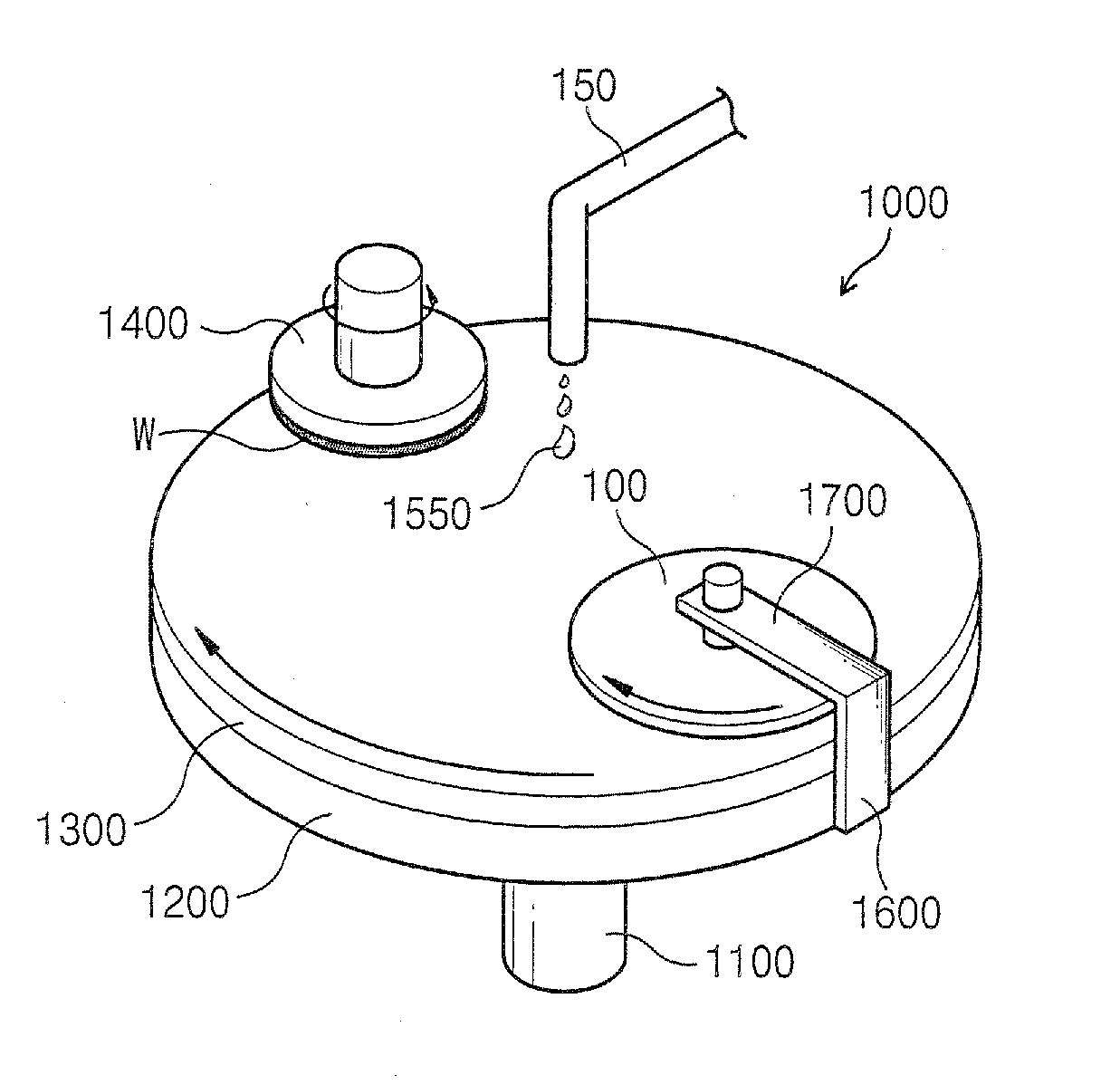

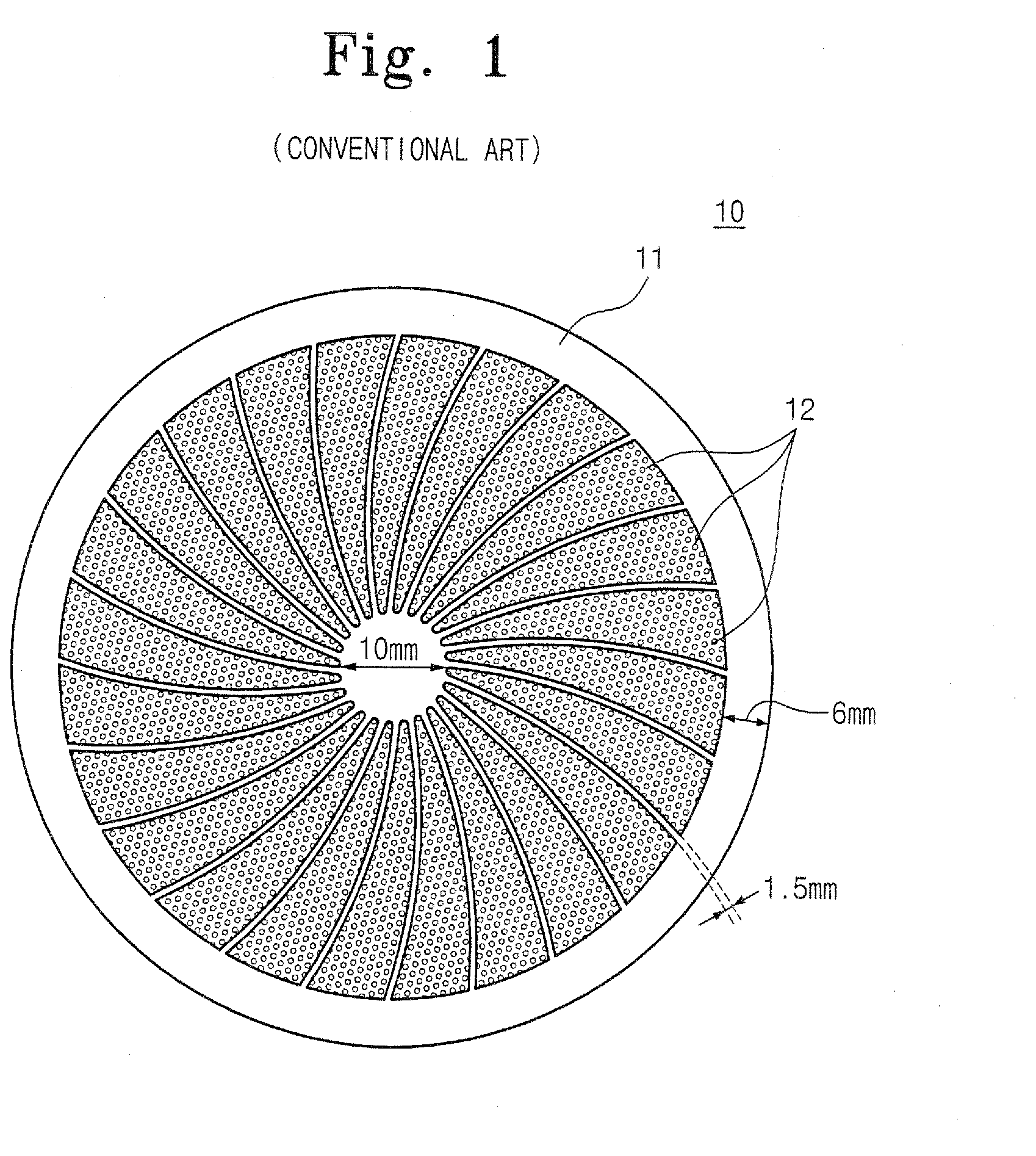

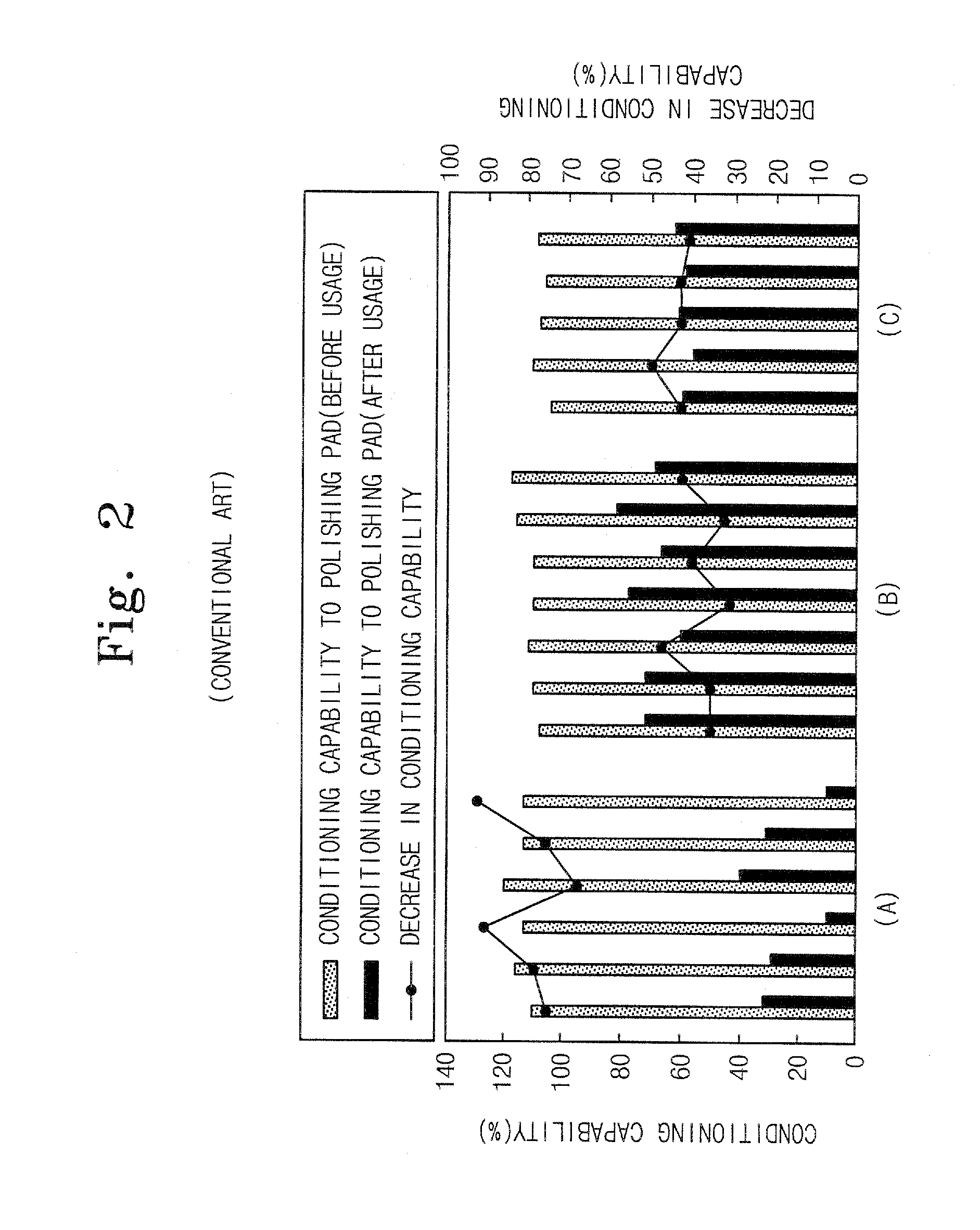

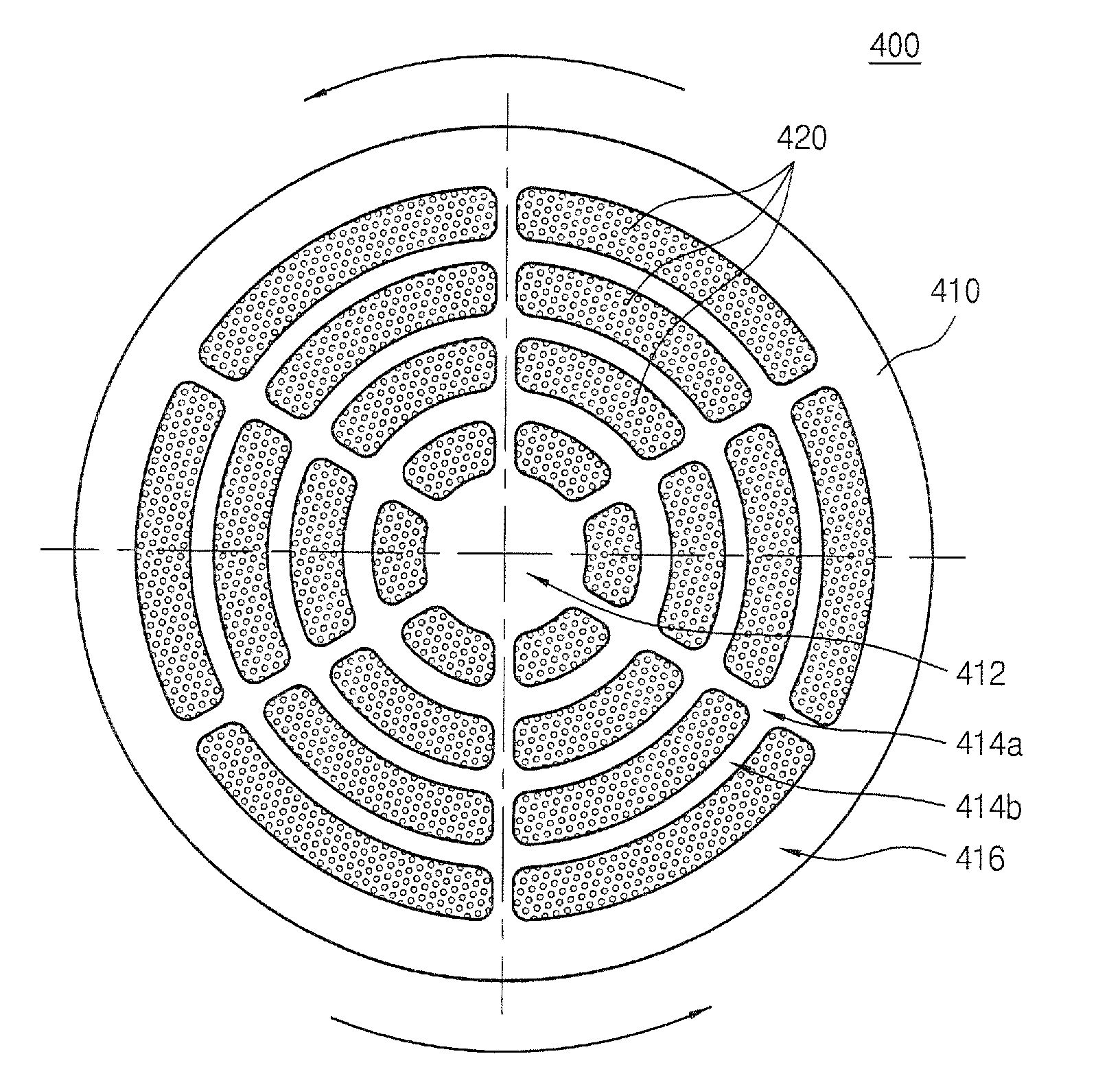

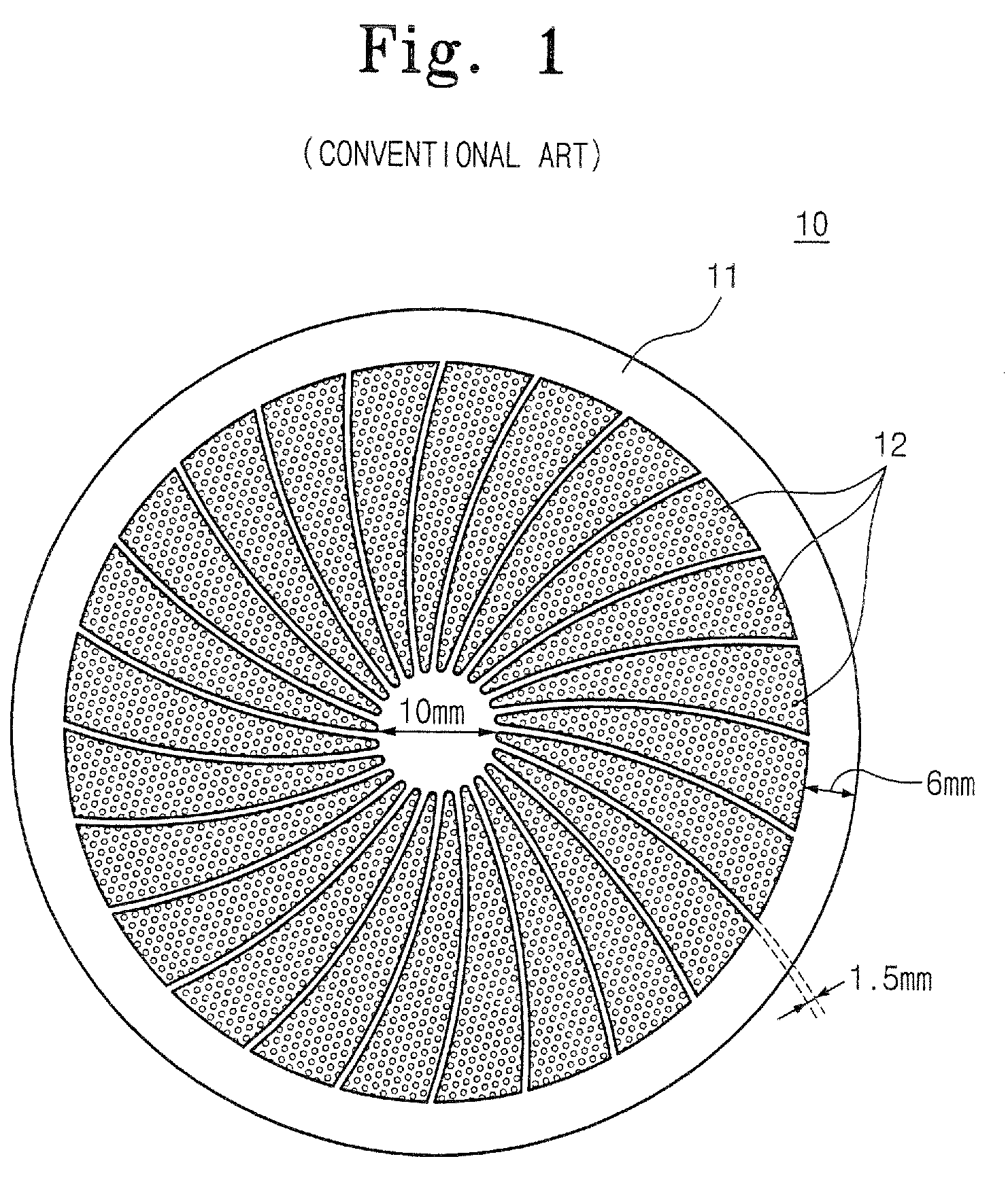

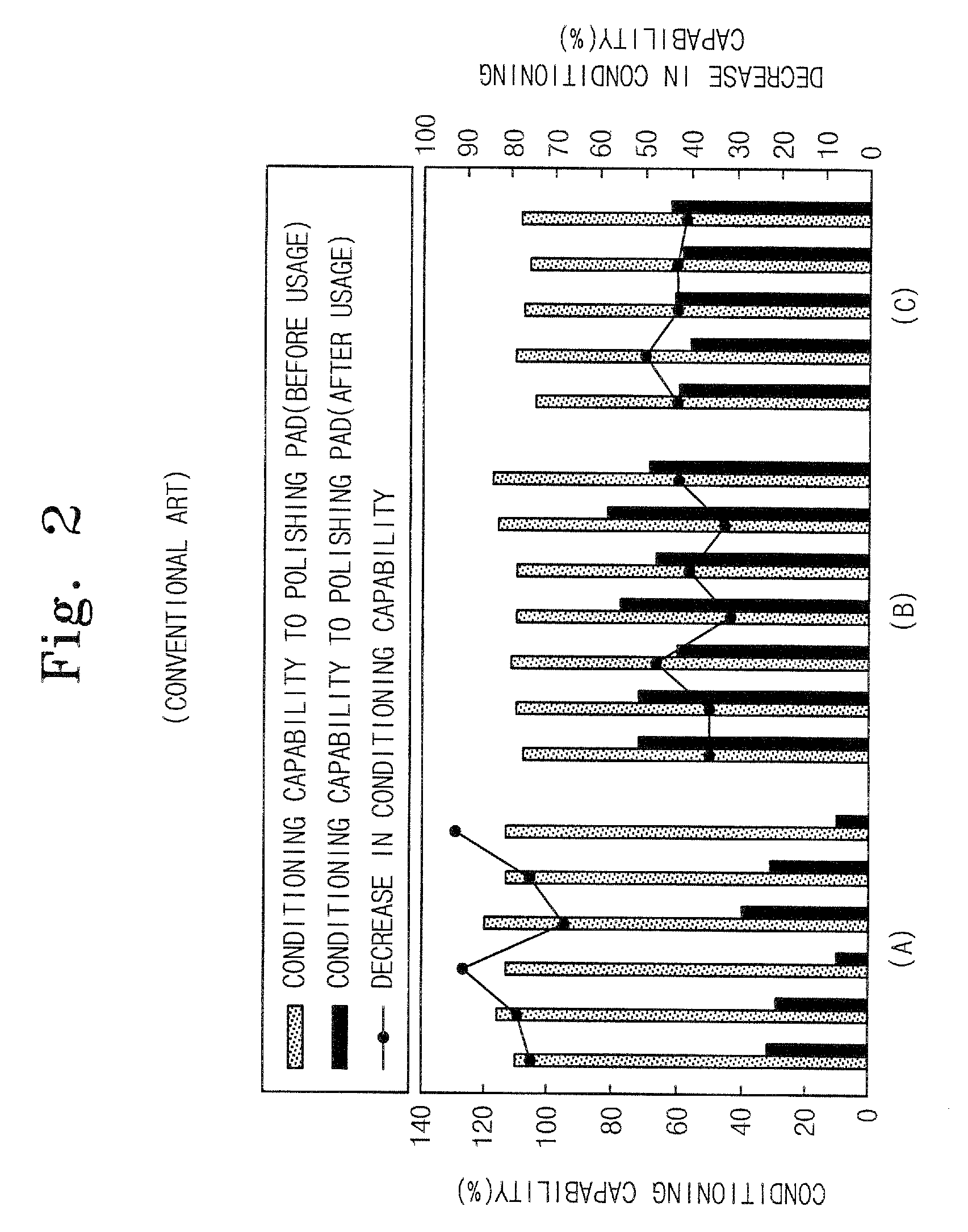

Conditioner device for conditioning polishing pad and chemical mechanical polishing apparatus including the same

InactiveUS20070167117A1Improve mobilityReduce wearEdge grinding machinesPolishing machinesRotational axisSlurry

The present invention relates to a conditioner device for polishing pad and a chemical mechanical polishing (CMP) apparatus having the same. The conditioner device of the present invention comprises a rotable support plate including a support plate surface comprising a center area located about the rotational axis of the support plate, a mid area surrounding the center area, and a peripheral area surrounding the mid area, a plurality of conditioning zones located within a portion of the mid area of the support plate surface. A plurality of hard particles which are densely arranged within the conditioning zones and are attached to the support plate surface. A plurality of passages defined by the conditioning zones within which a slurry flows, the passages occupying a portion of the mid area which is not occupied by the conditioning zones, the center area and the peripheral area.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for conditioning urban sludge by agent compounding

InactiveCN108083609AImprove dehydration effectCalorific valueSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentDewatered sludgeMoisture

The invention discloses a method for conditioning urban sludge by agent compounding. The method comprises (1) adjusting pH through an acid solution, then adding iron powder and activated carbon powderinto sludge, carrying out full stirring mixing, starting an aeration device to condition and transferring a part of substances in the sludge into the liquid phase, (2) adding a persulfate into the sludge conditioned in the previous step, activating the persulfate through ferrous ions, oxidizing to break the sludge so that combined water, adsorbed water, interstitial water and free water in the sludge are partially separated, the dewaterability is improved and SCOD, proteins and polysaccharide in the sludge are increased, and (3) after sludge conditioning, carrying out mechanical dewatering toobtain dewatered sludge. The method can reduce the moisture content of the urban sludge from 97 to 99% to 55 to 60%, greatly reduce the specific resistance and volume of the sludge, greatly improve the combustion calorific value, realize harmlessness, stabilization, reduction and recycling of sludge and has a wide application prospect.

Owner:NANCHANG HANGKONG UNIVERSITY

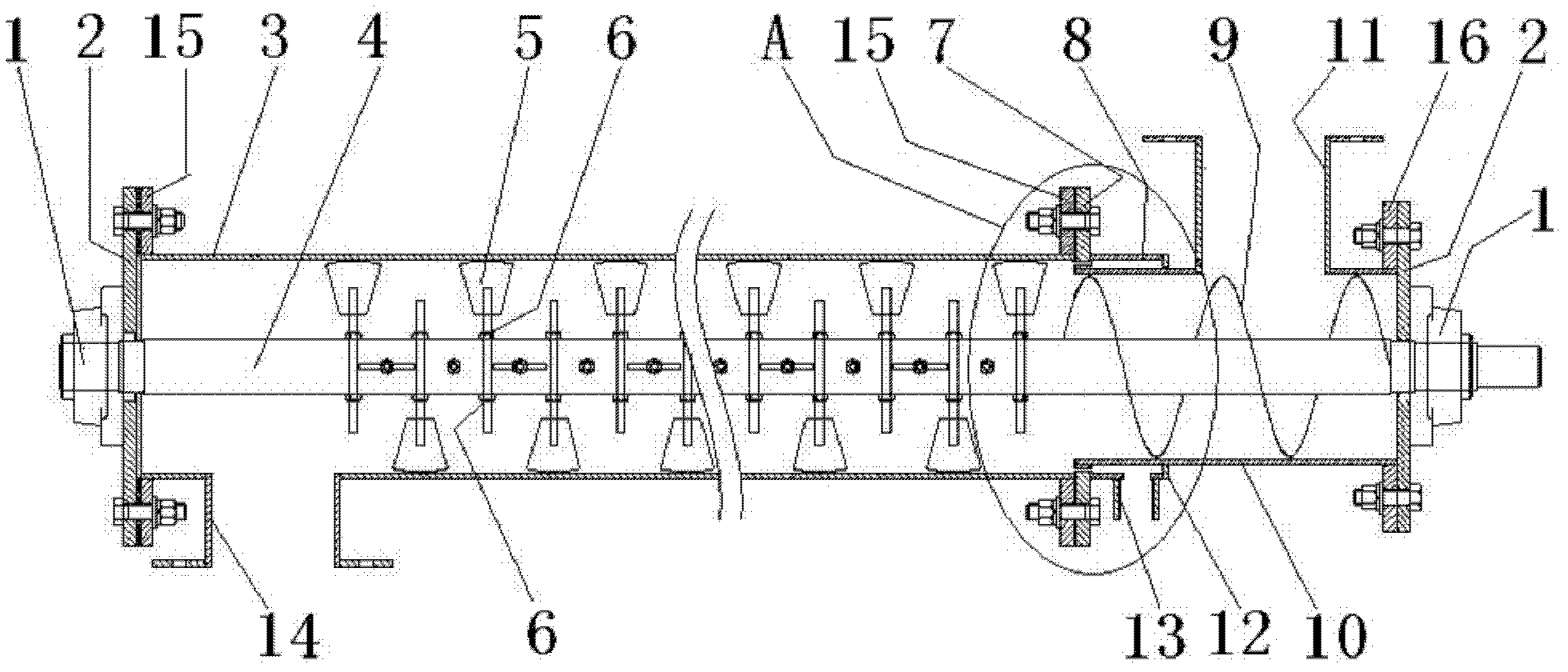

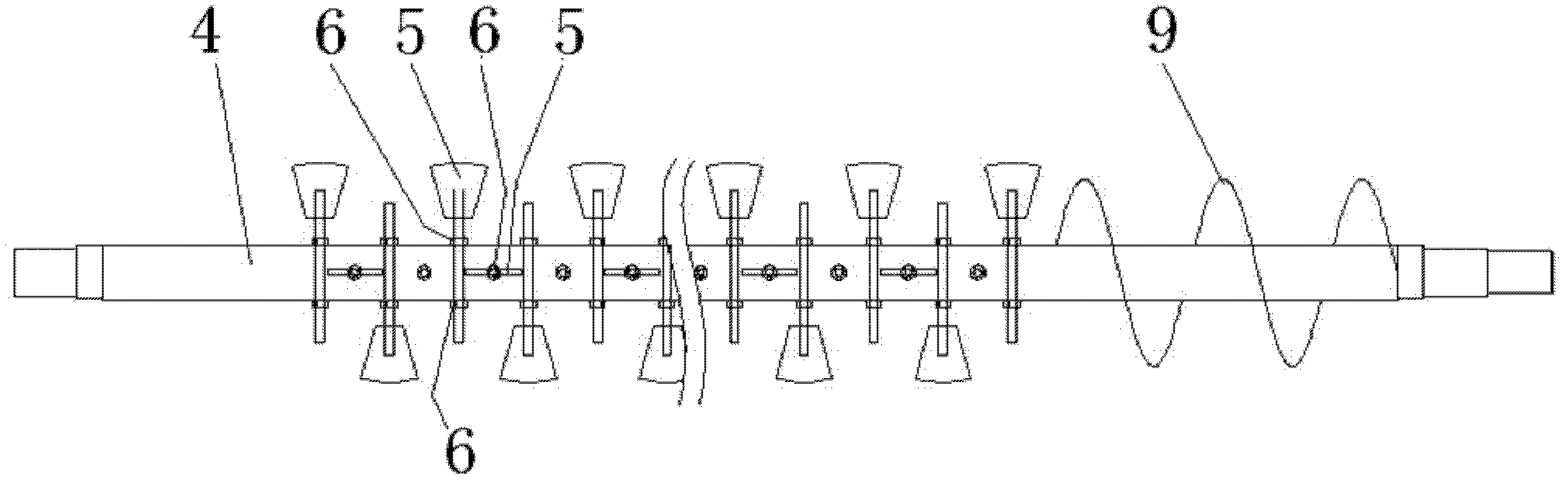

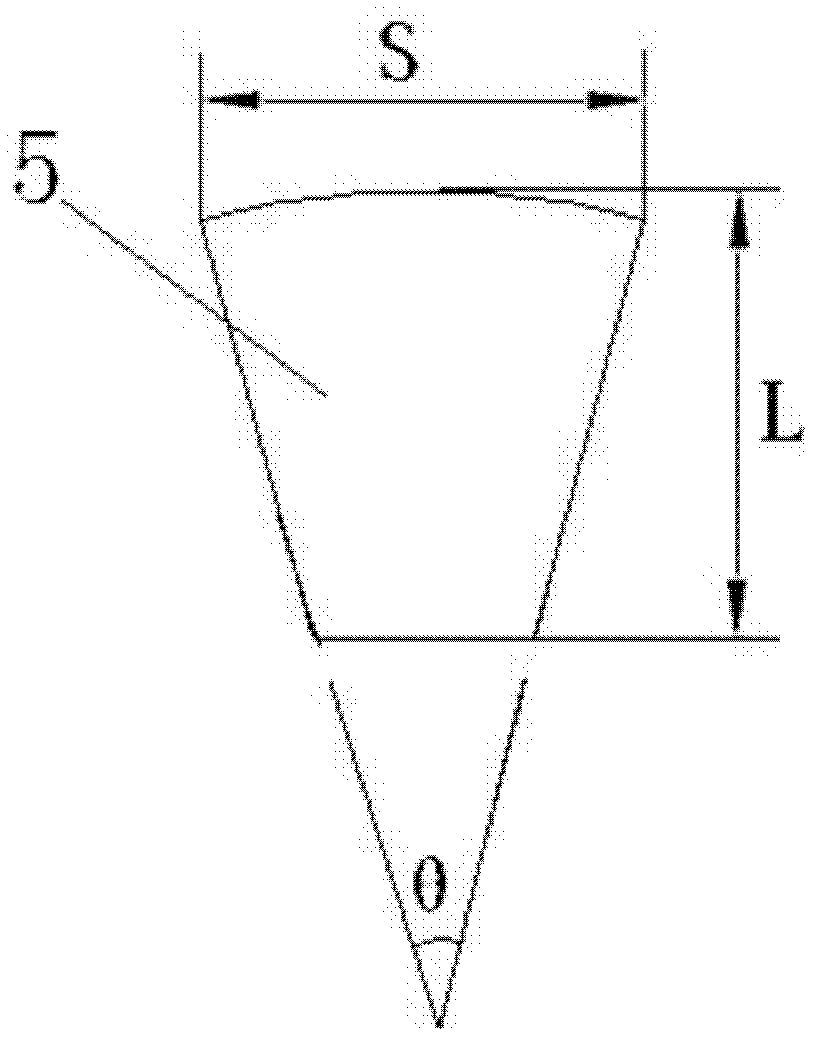

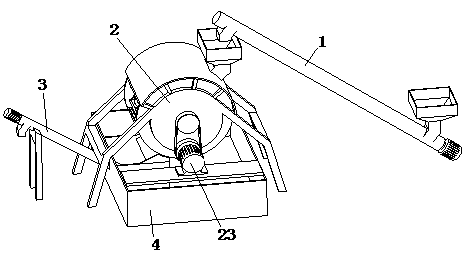

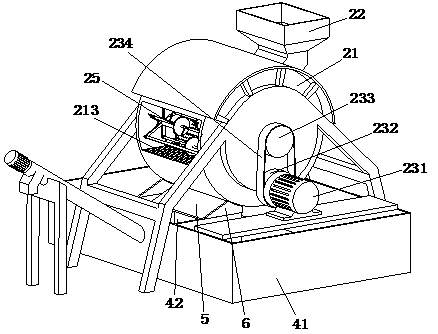

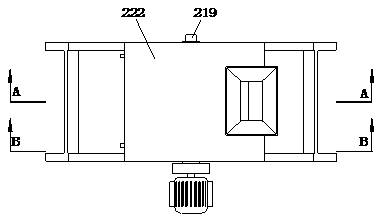

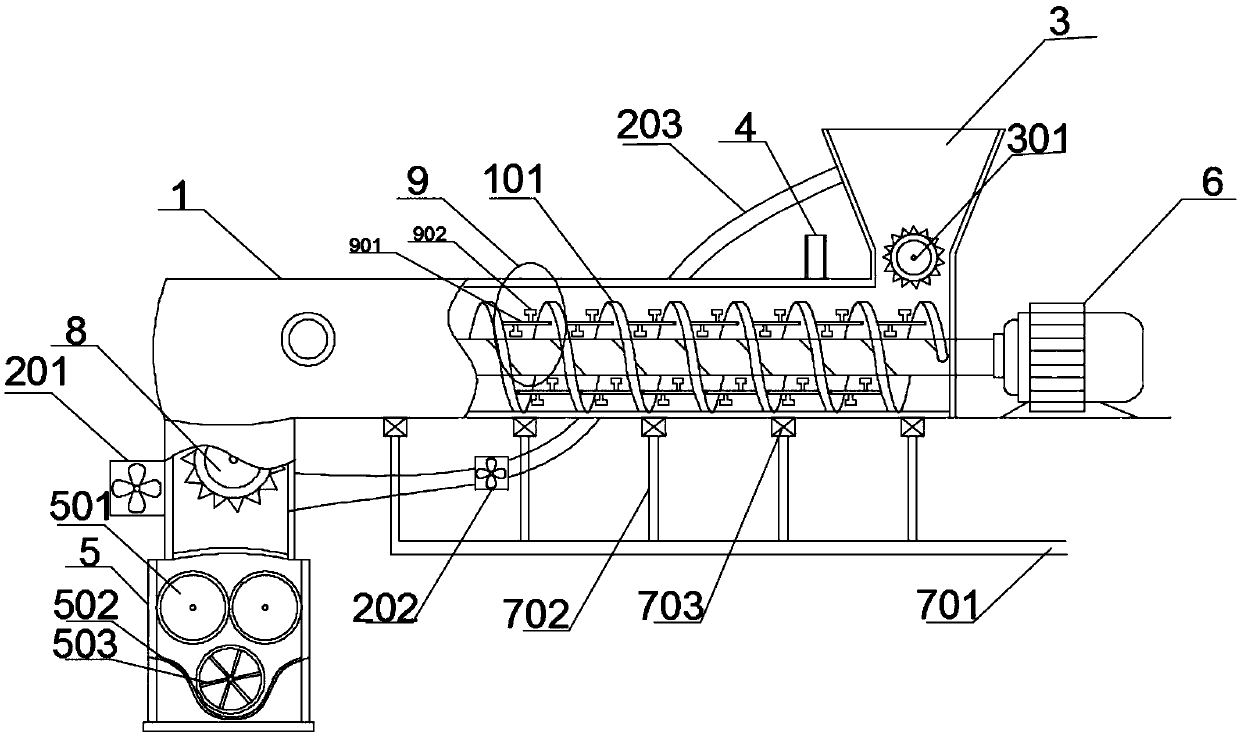

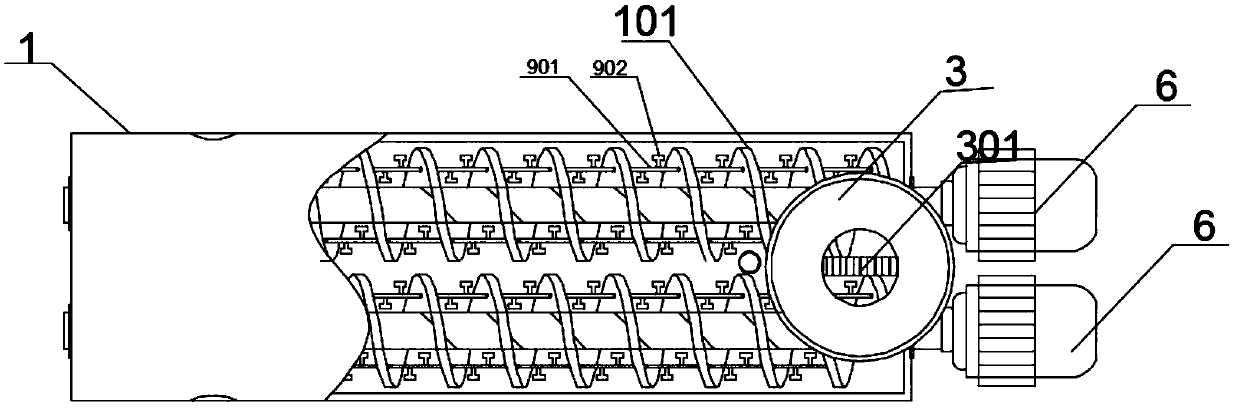

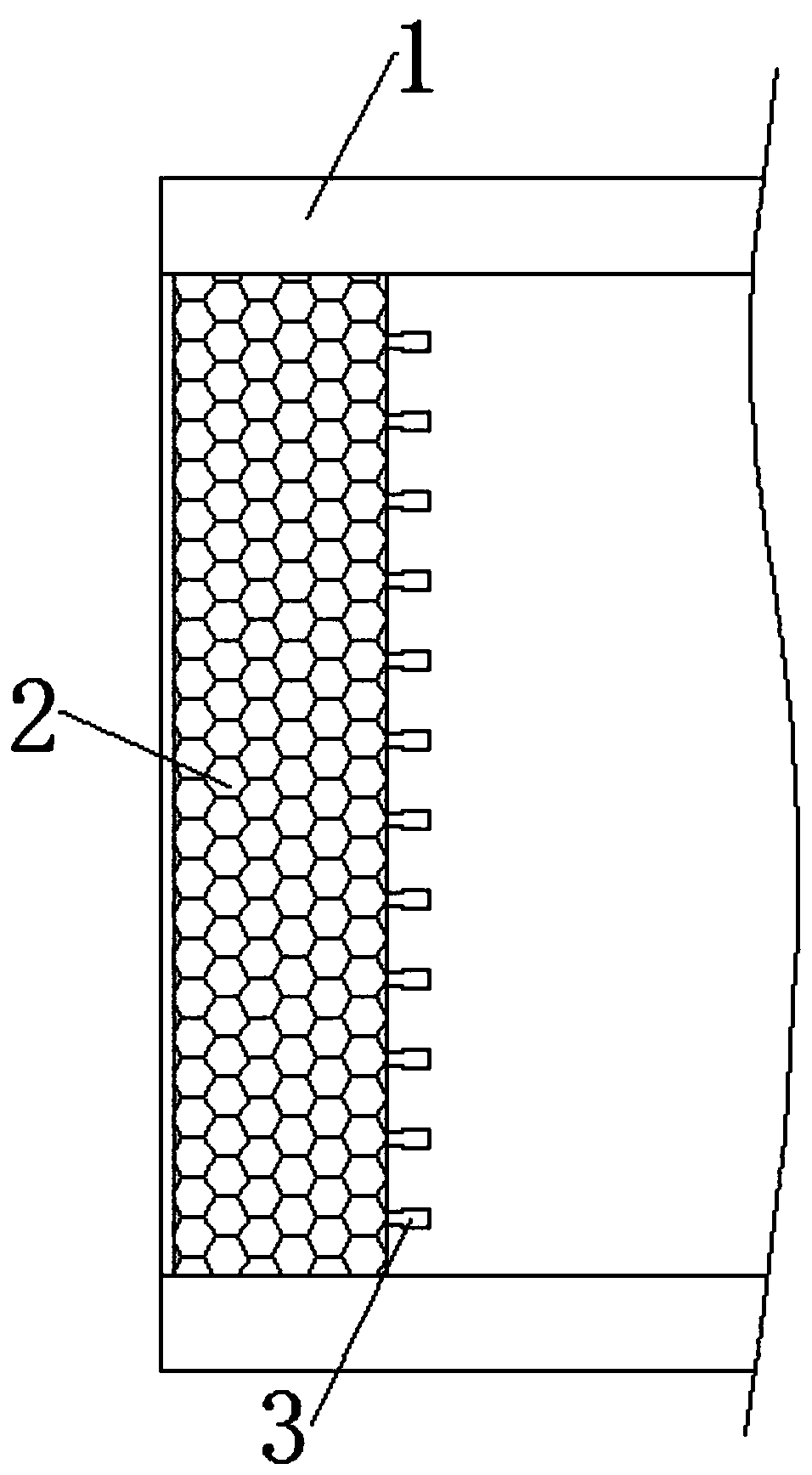

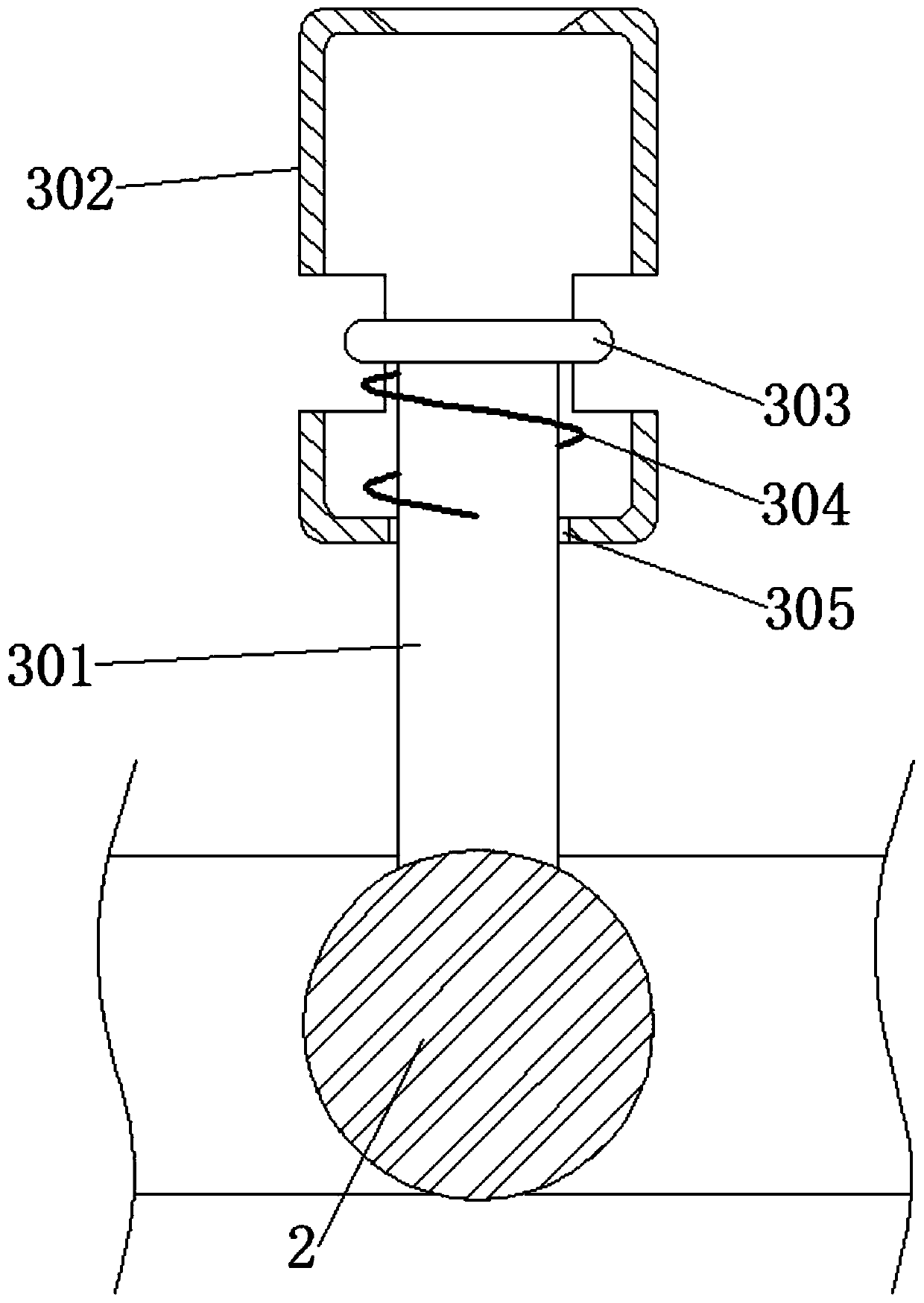

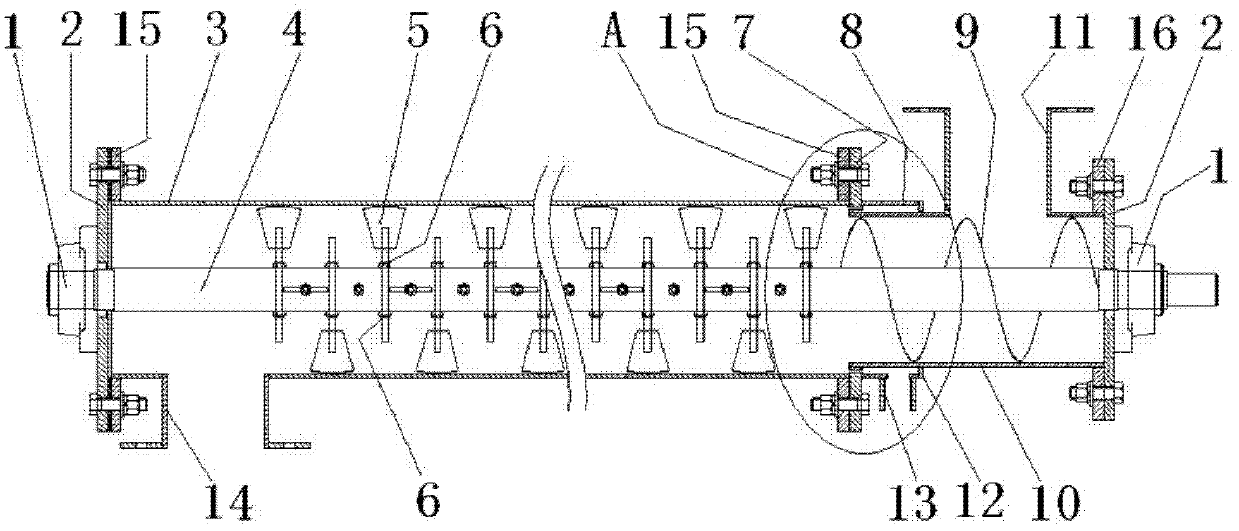

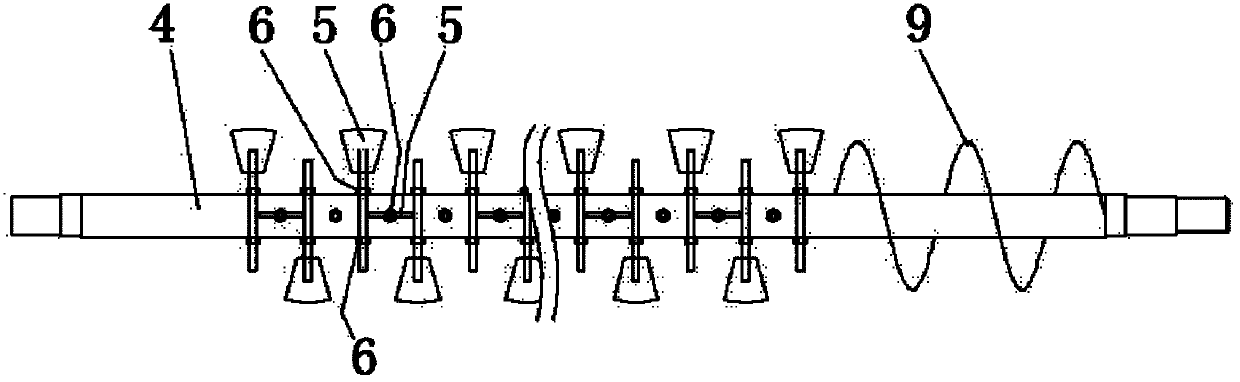

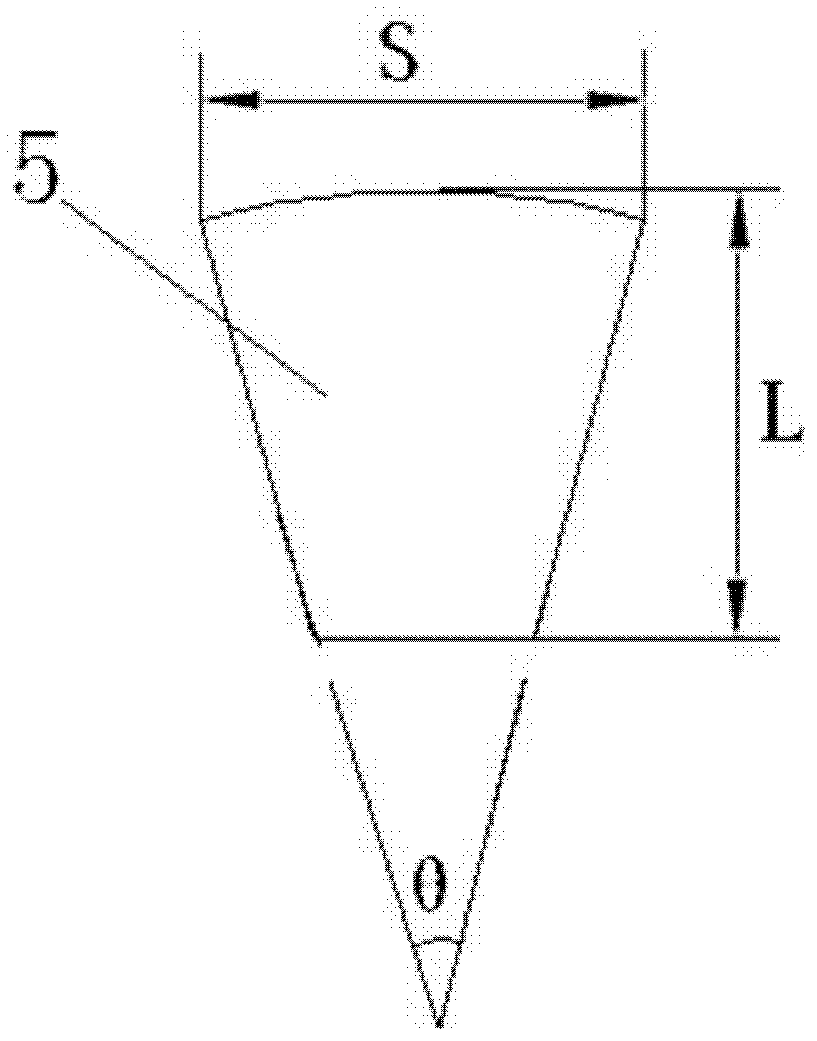

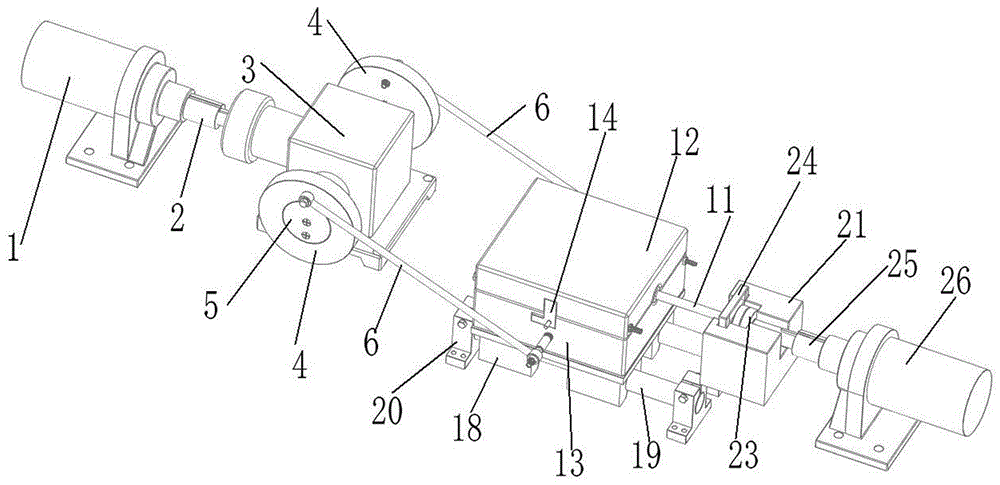

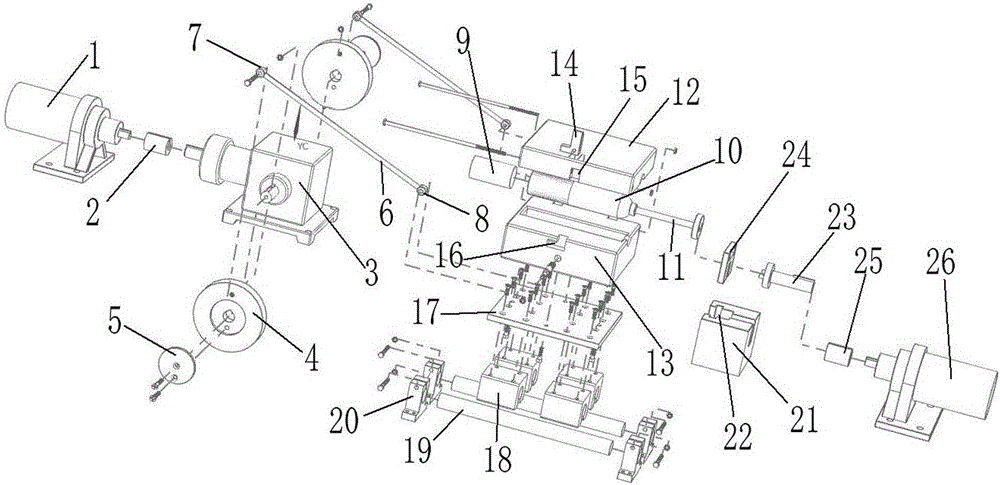

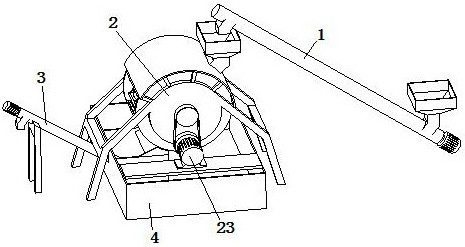

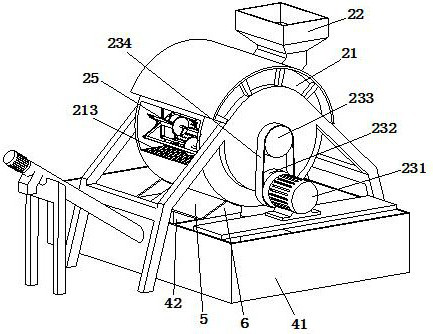

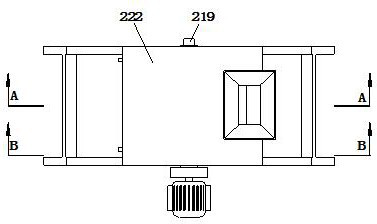

Small-sized conditioner for testing

InactiveCN102511906AInhibit refluxReduce wear and tearFeeding-stuffHelical bladePulp and paper industry

The invention belongs to the technical field of food feed machinery, and relates to a small-sized conditioner for testing. The small-sized conditioner is formed by a conditioner shell and a conditioner rotor, wherein the conditioner rotor is arranged in the conditioner shell. In the invention, the diameter of a feed cavity is smaller than the diameter of a conditioning cavity, a feed section adopts a helical blade propelling mode, the adding for steam is carried out by adopting an axial multipoint adding mode, the steam can be added into materials in the conditioning cavity from steam adding holes which are annularly distributed on a steam adding flange after the steam enters into a steam cavity, the adding direction of the steam and the advancing direction of the materials are consistent, material seal is formed at the position of the steam adding holes, the backflow of the steam is prevented, and the materials can be preheated by the steam in the steam cavity. Compared with the conditioner in the prior art, more steam can be used for carrying out the transmission of heat and water with the materials, the consumption of the steam can be reduced, and the conditioning efficiency and the conditioning quality are increased; and the angle of a helical blade is adjustable, and thus parameter related to a conditioning technology of feed or food can be optimized. The small-sized conditioner disclosed by the invention is suitable to be used for a scientific test and research in feed or food industry.

Owner:CHINA AGRI UNIV

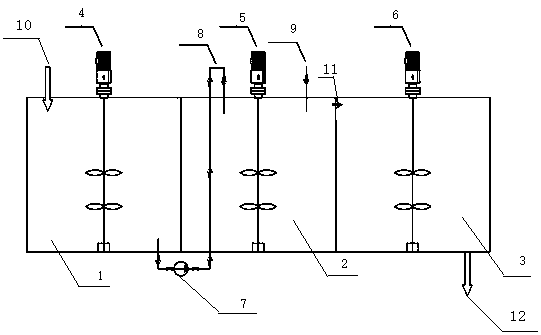

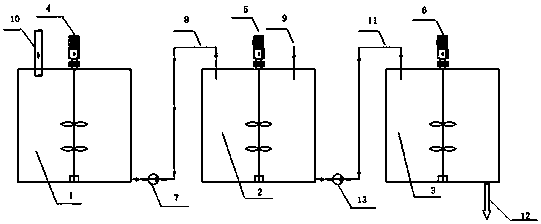

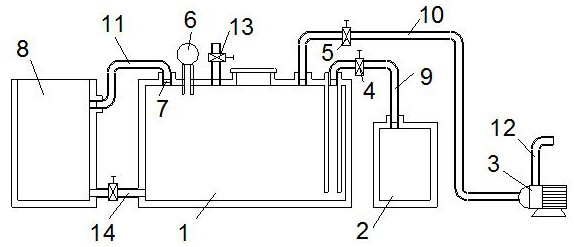

Combined sludge conditioning tank and continuous sludge conditioning process

PendingCN111039543AResolution timeSolve efficiency problemsSludge treatment by de-watering/drying/thickeningTransportation and packagingSludgeBuffer tank

The invention relates to a combined sludge conditioning tank and a continuous sludge conditioning process. The combined sludge conditioning tank comprises a buffer tank, a sludge and agent mixing tankand a homogenizing tank, wherein the upper portion of the buffer tank is provided with a sludge inlet, the lower portion of the buffer tank is provided with a sludge conveying pipeline communicated with the upper portion of the sludge and agent mixing tank, the sludge conveying pipeline is provided with a sludge conveying pump, an agent feeding port is formed in the top of the sludge and agent mixing tank, a channel for communicating the sludge and agent mixing tank and the homogenizing tank is arranged between the sludge and agent mixing tank and the homogenizing tank, a sludge outlet is formed in the lower portion of the homogenizing tank, and the buffer tank, the sludge and agent mixing tank and the homogenizing tank are respectively provided with an independent mixing stirrer. The invention further discloses a continuous sludge conditioning process using the combined sludge conditioning tank. With the application of the combined sludge conditioning tank to condition sludge, the agent and sludge mixing conditioning effect can be guaranteed to the maximum extent, the conditioning time is shortened, the sludge conditioning efficiency is improved, the number, the volume and the occupied area of the conditioning tank are reduced, and the investment cost is reduced.

Owner:湖南隆泰资源再生利用技术有限公司

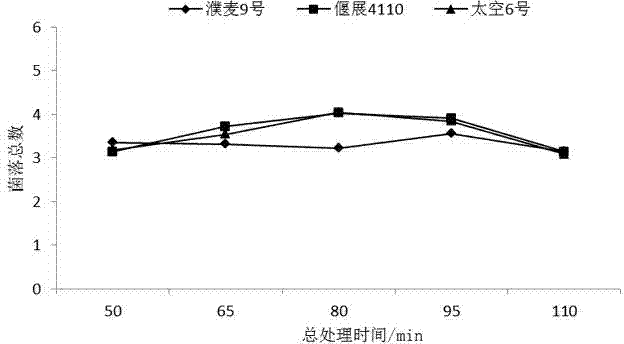

Conditioning method capable of reducing microorganism content in wheat

InactiveCN104226402AReduce conditioning timeImprove conditioning efficiencyGrain millingAgricultural scienceEngineering

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

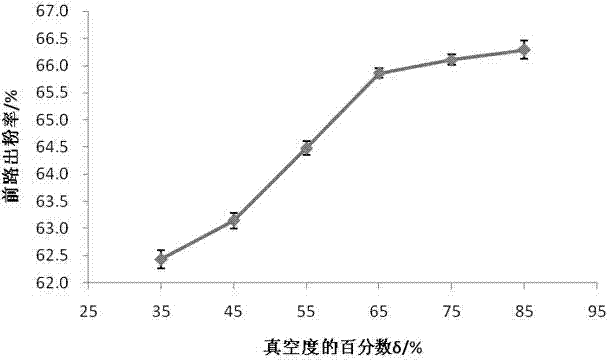

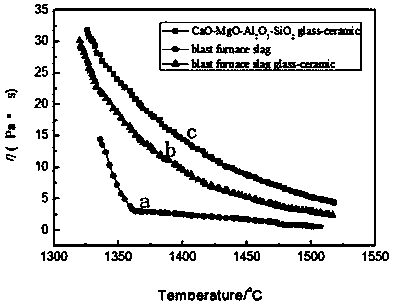

Component tempering material suitable for tempering blast furnace molten slag to prepare microcrystal glass and tempering method

The invention discloses a component tempering material suitable for tempering blast furnace molten slag to prepare microcrystal glass. The component tempering material comprises the raw materials in parts by mass: 6-22 parts of quartz sand, 3-5 parts of calcium sulfate, 2-8 parts of talcum powder, 0.5-2 parts of barium carbonate, 3.5-6 parts of soda feldspar powder, 2-4 parts of sodium fluosilicate, 1-4 parts of phosphorus pentoxide and 1-4 parts of float glass powder. The component tempering material disclosed by the invention is used for tempering the blast furnace molten slag to prepare themicrocrystal glass, and the method comprises the steps: firstly, uniformly mixing the component tempering material, and melting the mixture to obtain a component tempering material melt; and then, carrying out blending-melting on the component tempering material melt and the blast furnace molten slag to obtain a glass melt directly used for preparing the microcrystal glass. The component tempering material disclosed by the invention is used for tempering the blast furnace molten slag in a melt way, the implementation process is simple and easily controlled, and the tempering efficiency is high; and the tempered blast furnace molten slag can be directly used for producing microcrystal glass building decorative products by controlling the viscosity of the tempered blast furnace molten slag,so that the efficiency of preparing the microcrystal glass by using the blast furnace molten slag is increased, and the process step is simple and easily implemented.

Owner:WUHAN UNIV OF TECH

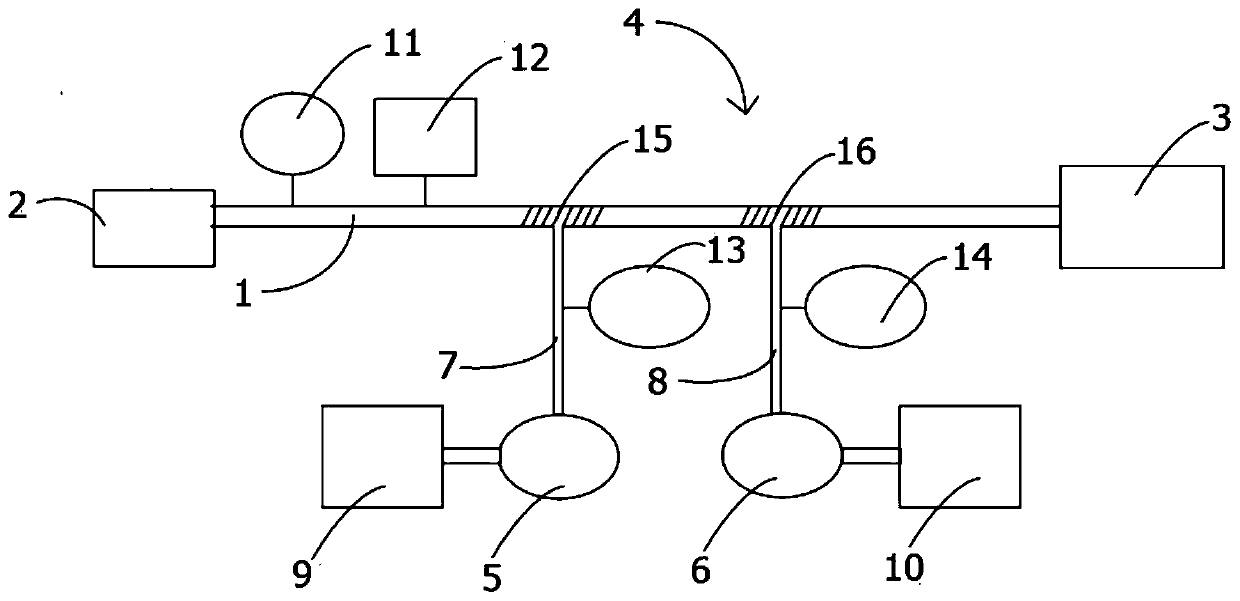

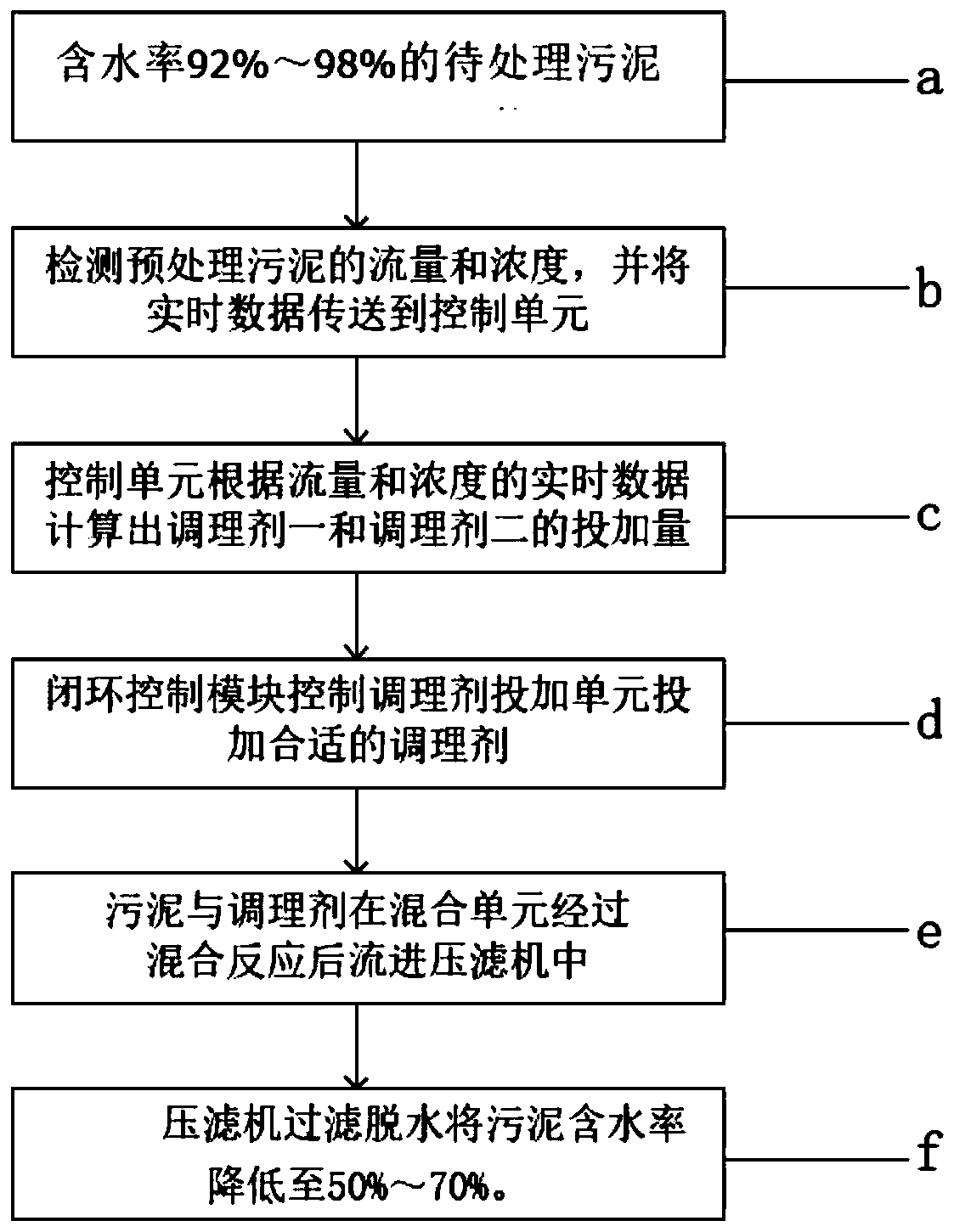

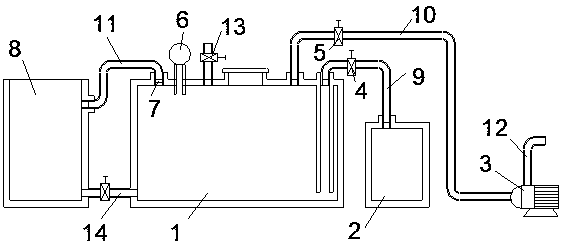

Sludge conditioning system and sludge conditioning method

InactiveCN110498590ASmall footprintLarge footprint, long conditioning cycle, low conditioning efficiencySludge treatment by de-watering/drying/thickeningSludgeControl cell

The invention provides a sludge conditioning system and a sludge conditioning method. The system comprises a sludge inlet pump and a filter press which are connected through a sludge inlet pipeline, and a conditioning mechanism, the conditioning mechanism comprises a conditioner adding unit, a detection unit, a mixing unit and a control unit, the conditioner adding unit is connected with the sludge inlet pipeline through a pipeline, the detection unit can detect the flow rate and concentration of sludge and the flow rate of a conditioner in real time, the mixing unit makes the conditioner andthe sludge mixed and reacted, and the control unit can adjust the adding amount of the conditioner according to the sludge with different flow rates and concentrations. The reasonable adding amount ofthe conditioner is adjusted by detecting the flow rate and concentration of the sludge in real time, so the efficiency and effect of sludge conditioning are improved, and the occupied area of a conditioning tank is saved.

Owner:安徽省通源环境节能股份有限公司

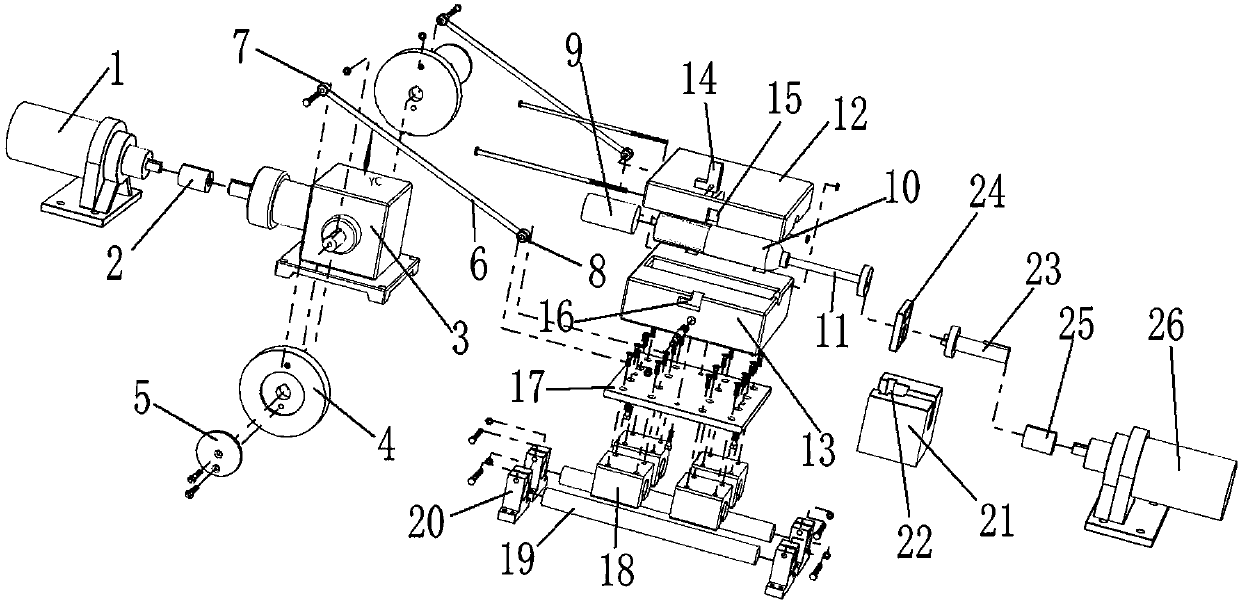

Sludge conditioner

ActiveCN110183093AReduce the stress of deep dehydrationIncrease the speed of temperingRotating receptacle mixersSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention relates to the field of sludge treatment equipment and particularly relates to a sludge conditioner. The sludge conditioner includes a feeding spiral conveyor, a conveying mechanism anda discharging spiral conveyor. The conveying mechanism includes a driving component, a feeding component, a conveying component, a transmitting component and a plurality of stirring components. The driving component is arranged on one side of the conveying component and the two are in transmission connection. The feeding component is arranged on an upper end of the conveying component. The transmitting component is arranged on the other end of the conveying component. The plurality of stirring components are circumferentially distributed in the conveying component. Each stirring component is in transmission connection with the conveying component through the transmitting component. A holding component is arranged right below the conveying component. When in use, the sludge conditioner disclosed by the invention can work continuously, thus improving conditioning efficiency of sludge. And during a conditioning process, separated sludge can be filtered out, reducing work amount during subsequent dewatering work. The sludge conditioner of the invention can also reduce labor intensity of equipment, prolonging the service life thereof.

Owner:深圳市鸿卓环保科技有限公司

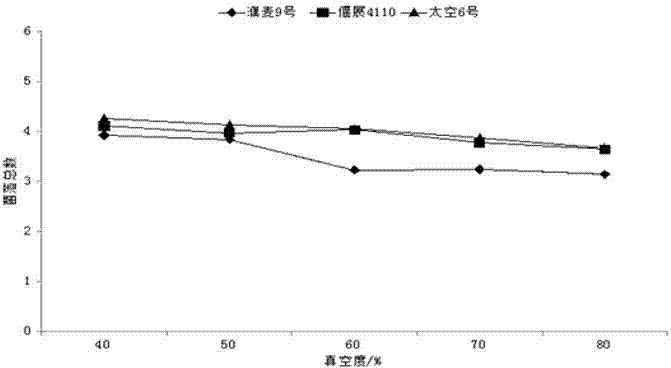

Modulation softening treatment method of wheat skin

The invention discloses a modulation softening treatment method of wheat skin. According to the modulation softening treatment method of wheat skin, water vapor of edible alcohol is adopted for carrying out vapor softening treatment on wheat, the penetration speed of water to wheat is increased by utilizing a thermal and chemical method for treatment, wheat wetting treatment is achieved in a shorttime, scraping of wheat flour is facilitated, the efficiency of flour making is improved, and meanwhile because the edible alcohol is used, not only the disinfection effect is achieved, and certain winey smell can be given to the wheat; and furthermore, because of the micro puffing effect brought by microwave heating treatment, physicochemical separation between wheat cortexes and endosperm is promoted, the disinfection effect on the wheat can be further improved, and then the wheat is subjected to vacuum modulation treatment so that modulation softening treatment on the wheat can be completed. Cortex toughness of the wheat is improved, the wheat is enabled to be in the suitable flour making state, the flour yield is effectively improved, the ash content in the flour is decreased, breeding and propagation of microorganisms in the modulation process are reduced, and therefore, the process performance and eating quality of the flour are improved.

Owner:涡阳县丰华面业有限公司

Conditioner device for conditioning polishing pad and chemical mechanical polishing apparatus including the same

InactiveUS7578727B2Improve mobilityMaintain surface roughnessEdge grinding machinesPolishing machinesRotational axisSlurry

The present invention relates to a conditioner device for polishing pad and a chemical mechanical polishing (CMP) apparatus having the same. The conditioner device of the present invention comprises a rotable support plate including a support plate surface comprising a center area located about the rotational axis of the support plate, a mid area surrounding the center area, and a peripheral area surrounding the mid area, a plurality of conditioning zones located within a portion of the mid area of the support plate surface. A plurality of hard particles which are densely arranged within the conditioning zones and are attached to the support plate surface. A plurality of passages defined by the conditioning zones within which a slurry flows, the passages occupying a portion of the mid area which is not occupied by the conditioning zones, the center area and the peripheral area.

Owner:SAMSUNG ELECTRONICS CO LTD

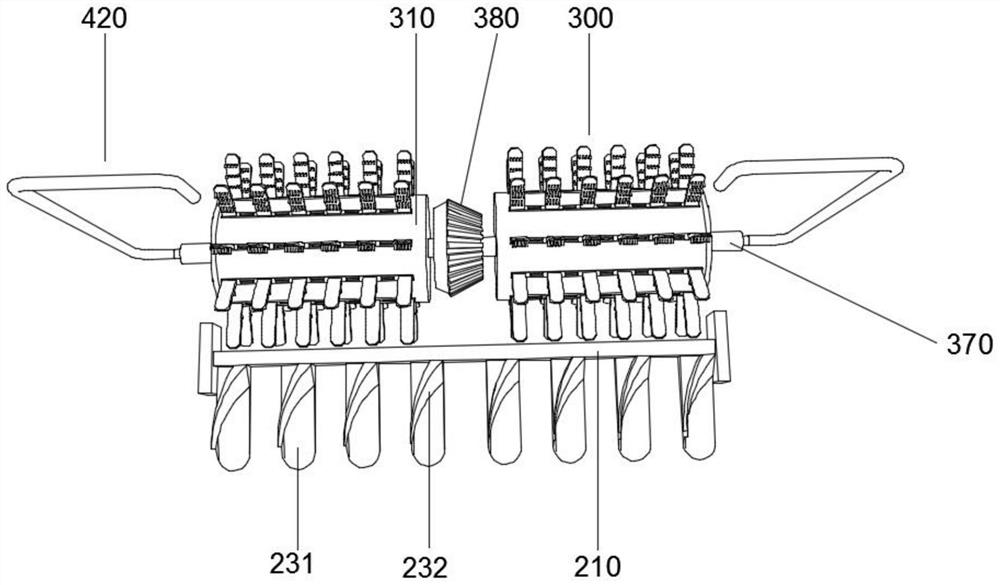

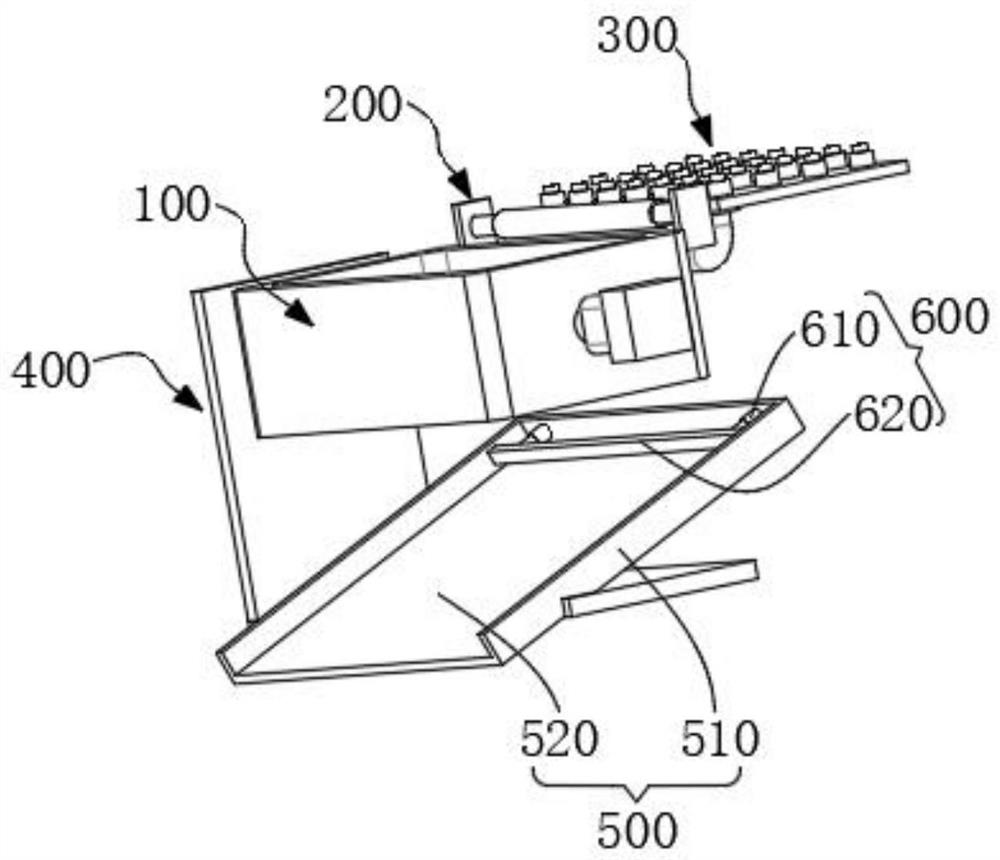

Conditioning and granulating integrated apparatus

The invention discloses a conditioning and granulating integrated apparatus, relates to the technical field of feed processing mechanical equipment and is intended to solve the problem that existing equipment has difficulty in providing quick granulating after conditioning and has low working efficiency. The conditioning and granulating integrated apparatus comprises a conditioning portion and a granulating device; the conditioning portion includes a conditioning barrel, a screw device and a steam device; a feed bucket is arranged above one end of the conditioning barrel; a discharge port is arranged below the other end of the conditioning barrel; the granulating device is fixedly connected with the discharge port; the steam device is arranged below the conditioning barrel. The conditioning and granulating integrated apparatus also comprises a preheating device and a reinforced stirring device; the preheating device includes a blower, a suction fan and an air exchange pipe; the reinforced stirring device includes a fixing connection rod horizontally fixed on the screw device and a T-shaped stirring plate arranged on the fixing connection rod; the screw device also has a guide strip. The conditioning and granulating integrated apparatus can provide quick granulating after conditioning and has the advantages that feed materials are preheated, steam is utilized efficiently, and energy is saved.

Owner:华蓥市明月镇小学

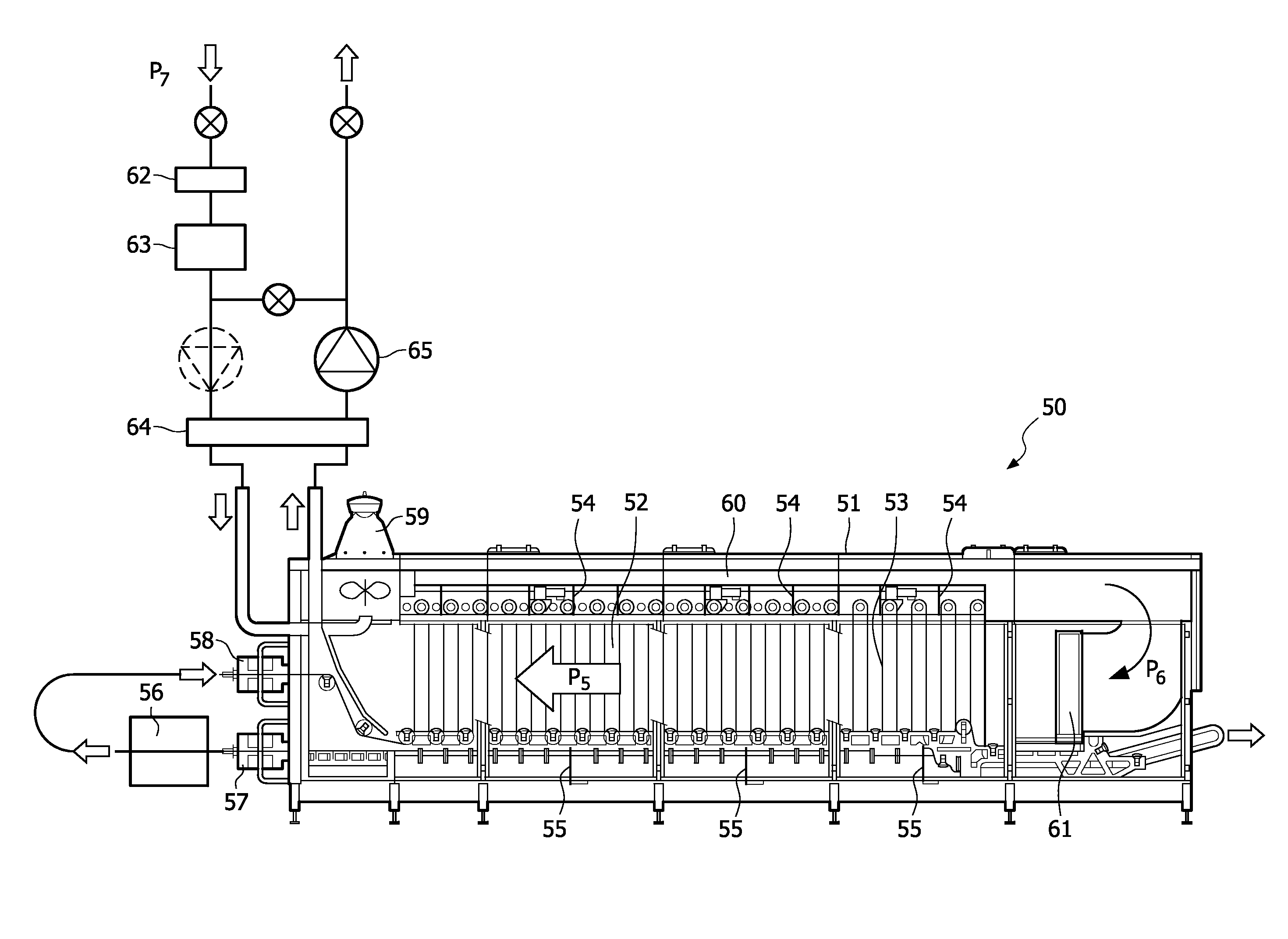

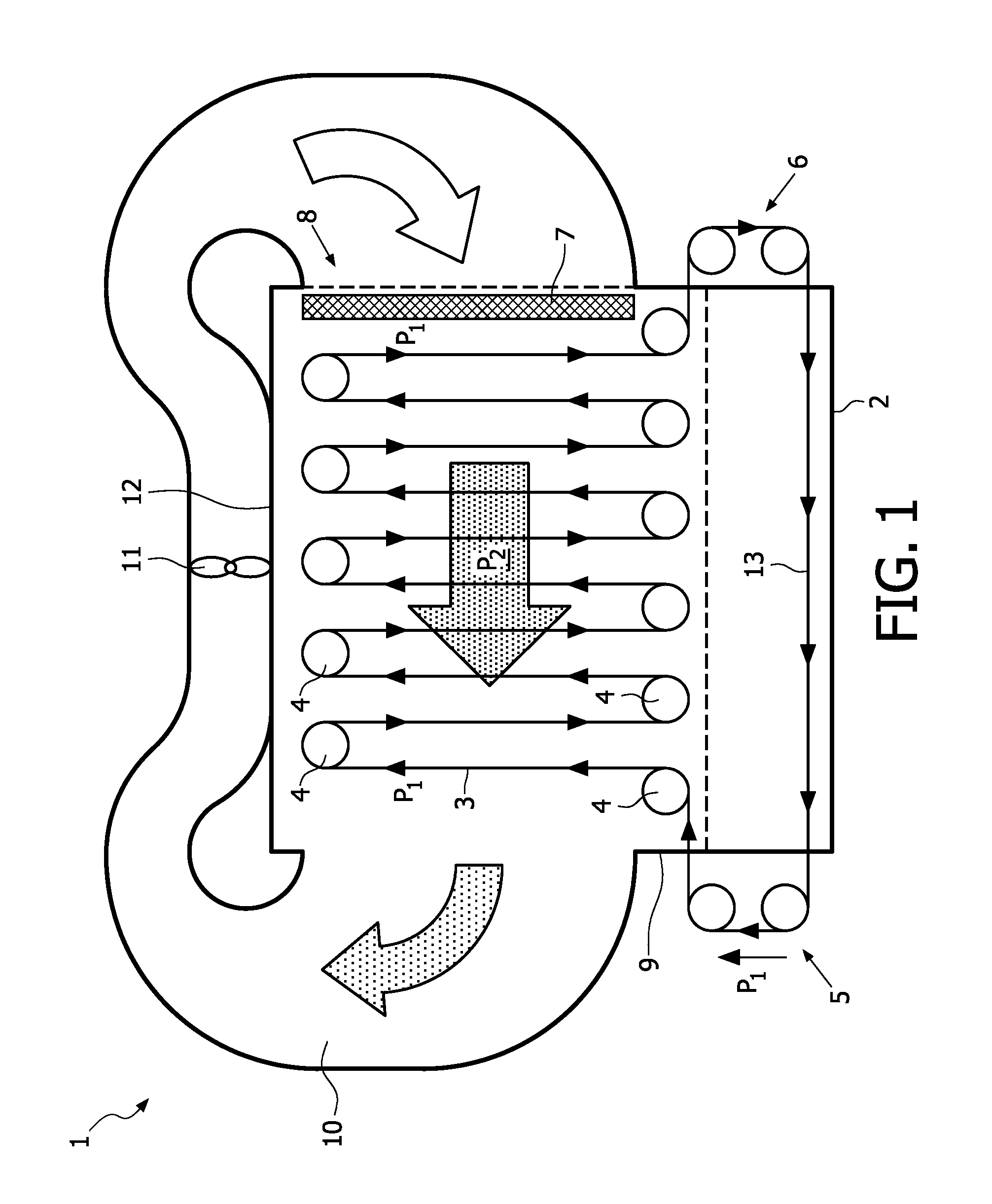

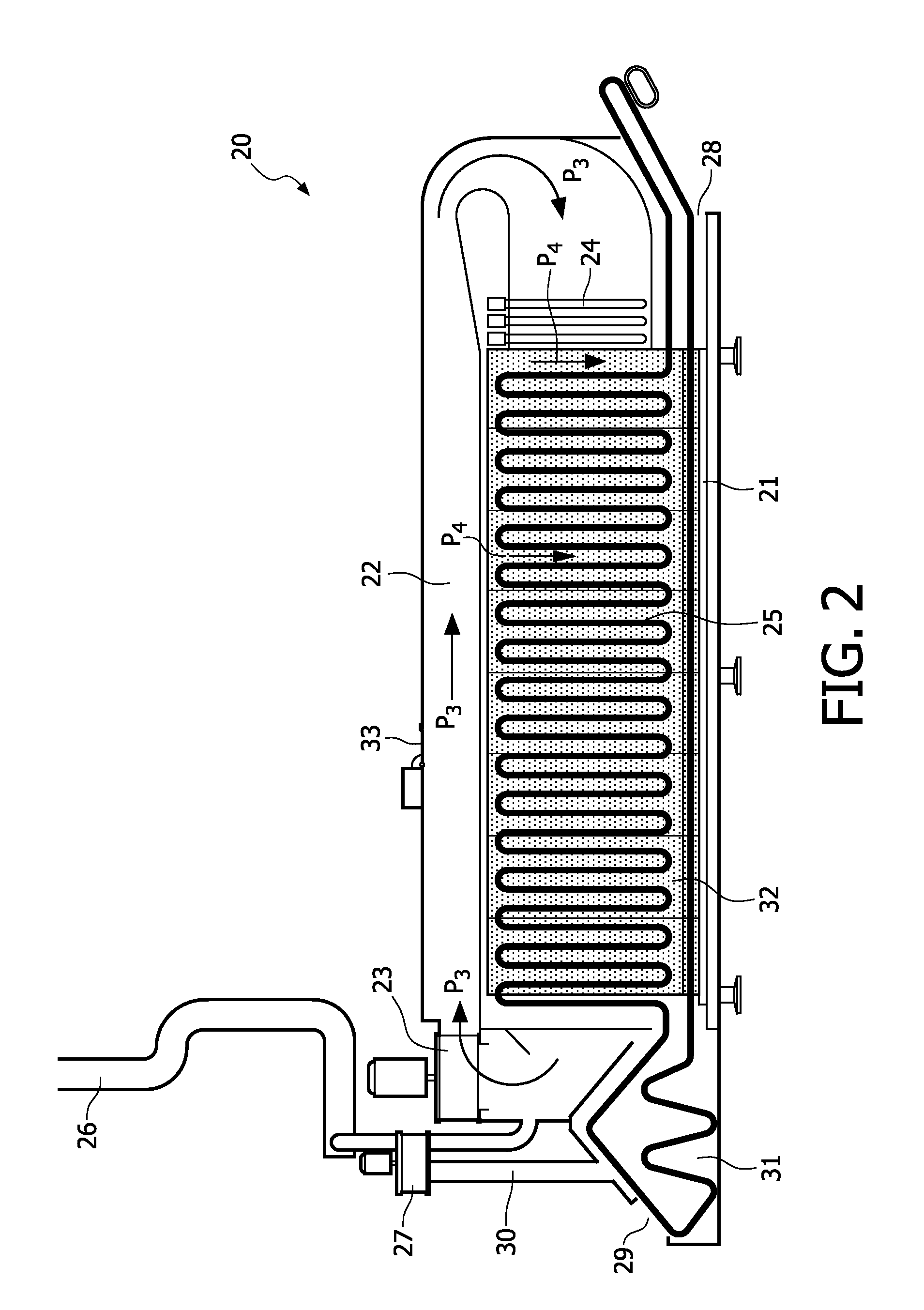

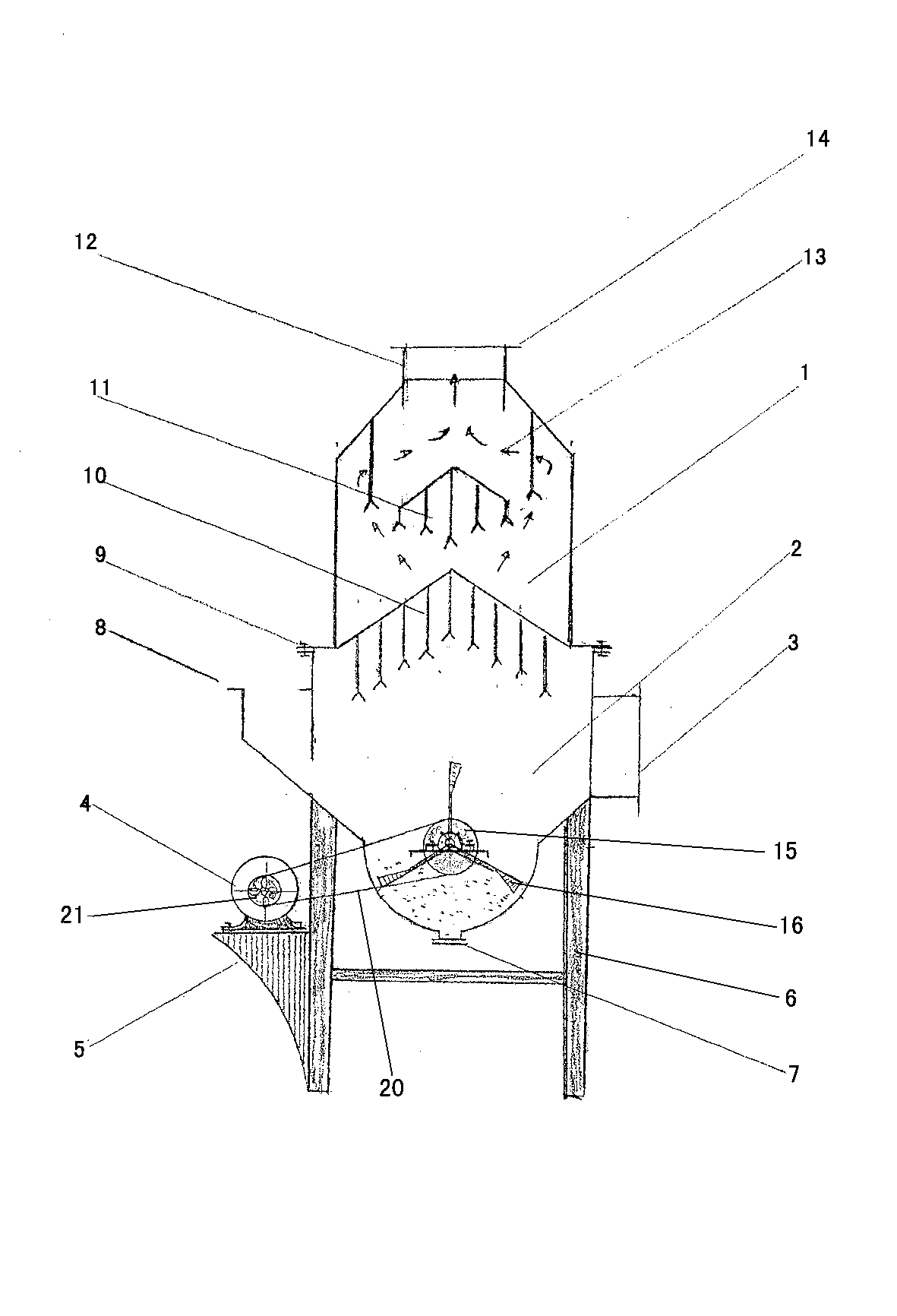

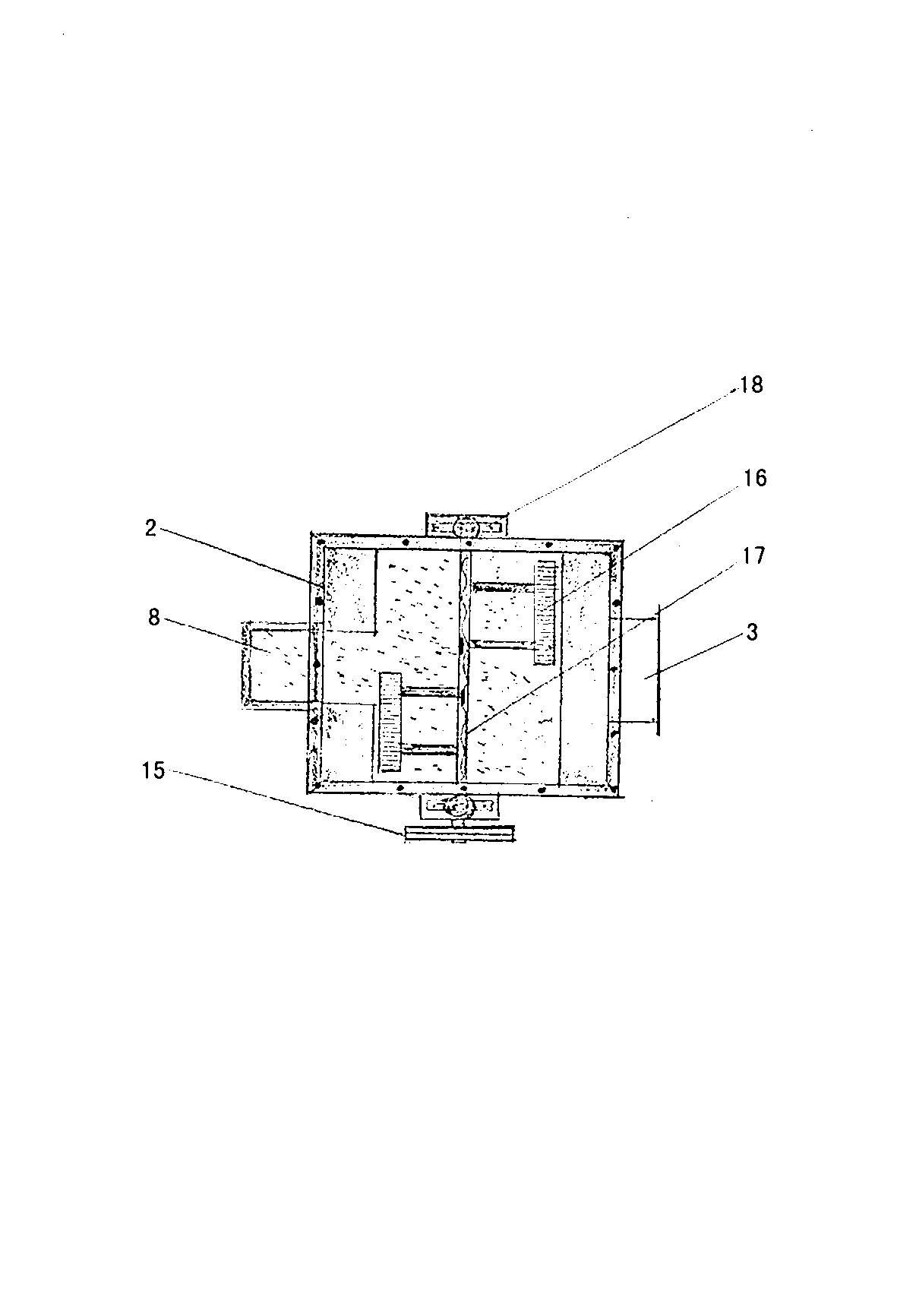

Device for treating elongate food products with a conditioned airflow

ActiveUS8474373B2Improve conditioning efficiencyOptimal control methodDomestic stoves or rangesElectrical heating fuelEngineeringProcess engineering

The present invention relates to a device for treating elongate food products in a process space using a conditioned airflow, comprising: a housing bounding the process space, with a feed opening arranged in the housing and a discharge opening arranged in the housing for respectively carrying elongate food products into the process space and discharging thereof from the process space, transport means for displacing the elongate food products through the process space, blowing means for generating an airflow in the process space, and conditioning means for conditioning the airflow.

Owner:STORK TOWNSEND BV

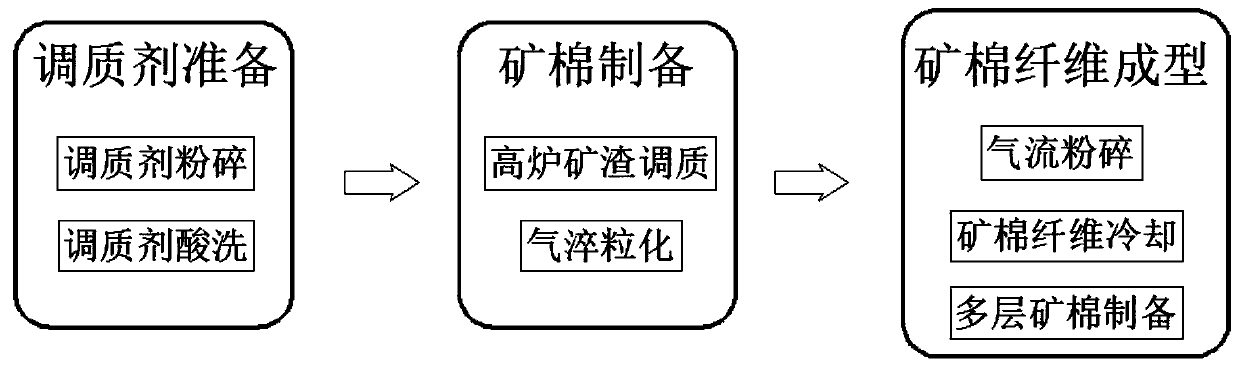

Novel multilayer mineral wool processing and preparing method

The invention discloses a novel multilayer mineral wool processing and preparing method, and belongs to the field of multilayer mineral wool preparation. According to the method, a conditioner is subjected to acid washing with diluted hydrochloric acid at a material preparation stage, such that the acid-insoluble substances in the conditioner are washed out, and the diluted hydrochloric acid can increase the acidity of the conditioner so as to improve subsequent conditioning efficiency; during the conditioning, the conditioner acid washing solution is subjected to dry distillation and acid washing through liquid-state blast furnace slag so as to save the energy for heating the conditioner acid washing solution and reduce the energy consumption in a mineral wool position limiting productionprocess; and in a subsequent airflow crushing link, the liquid-state blast furnace slag is subjected to fiber blowing by using disordered high-pressure airflow to prepare uniform mineral wool fibers,such that the blowing off of the mineral wool fibers by the high-pressure airflow during the fiber blowing can be avoided, the long mineral wool fibers are easy to prepare, the position limiting quality of the mineral wool is greatly improved, the processing performance of the mineral wool is improved, and the subsequent processing is convenient to perform.

Owner:惠州市嘉良保温材料有限公司

Flue gas conditioning and atomization acid/alkali comprehensive reaction tower

InactiveCN103120895AImprove conditioning efficiencySimple structureDispersed particle separationThermodynamicsFlue gas

The invention relates to a flue gas conditioning device, and particularly relates to a flue gas conditioning and atomization acid / alkali comprehensive reaction tower. In the prior art, a high-pressure spray mode including a spray gun, a spray nozzle, a pressure pump, a matching regulation system and an electric control system is usually used to perform mixing treatment on a reaction material and a medium. The price is low, and the deacidification effect is favorable, but crystalline powder must be subjected to fine screening before passing through the high-pressure spray nozzle, otherwise expected effect can not be achieved; and such treatment equipment is high in manufacturing cost. The flue gas conditioning device comprises an upper component, a middle component and a lower component, wherein the upper component and the middle component are connected through a square flange; and the lower component is a support leg fixed on the middle component. The flue gas conditioning device provided by the invention is high in conditioning efficiency, simple in structure and operating procedures, low in operation cost and convenient to maintain, can be matched with other waste incineration equipment, ensures that the reaction material (quicklime) does not need to be subjected to special screening, and realizes continuous stirring operation, sufficient medium mixing and low material energy consumption.

Owner:和田县绿海环保设备有限公司

Small-sized conditioner for testing

Owner:CHINA AGRI UNIV

Component tempering material suitable for blast furnace slag glass-ceramic and its tempering method

The invention discloses a component tempering material suitable for tempering blast furnace molten slag to prepare microcrystal glass. The component tempering material comprises the raw materials in parts by mass: 6-22 parts of quartz sand, 3-5 parts of calcium sulfate, 2-8 parts of talcum powder, 0.5-2 parts of barium carbonate, 3.5-6 parts of soda feldspar powder, 2-4 parts of sodium fluosilicate, 1-4 parts of phosphorus pentoxide and 1-4 parts of float glass powder. The component tempering material disclosed by the invention is used for tempering the blast furnace molten slag to prepare themicrocrystal glass, and the method comprises the steps: firstly, uniformly mixing the component tempering material, and melting the mixture to obtain a component tempering material melt; and then, carrying out blending-melting on the component tempering material melt and the blast furnace molten slag to obtain a glass melt directly used for preparing the microcrystal glass. The component tempering material disclosed by the invention is used for tempering the blast furnace molten slag in a melt way, the implementation process is simple and easily controlled, and the tempering efficiency is high; and the tempered blast furnace molten slag can be directly used for producing microcrystal glass building decorative products by controlling the viscosity of the tempered blast furnace molten slag,so that the efficiency of preparing the microcrystal glass by using the blast furnace molten slag is increased, and the process step is simple and easily implemented.

Owner:WUHAN UNIV OF TECH

A kind of biochemical sludge conditioning equipment

ActiveCN108545901BImprove conditioning efficiencyEasy to collectSludge treatment by de-watering/drying/thickeningGymnastic exercisingInjection portHigh pressure gas

The invention discloses a biochemical sludge conditioning equipment, which is characterized in that it comprises a pressure sludge storage tank, the pressure sludge storage tank has a sludge discharge port with a sealed switch cover, and the pressure sludge storage tank is also provided with The high-pressure gas inlet, the high-pressure gas inlet is connected with a high-pressure gas pipe, and the high-pressure gas pipe is provided with a gas pipe switch valve, and the end of the high-pressure gas pipe far away from the pressure sludge storage tank is also provided with a high-pressure gas adding device; the pressure sludge storage tank is also provided with There is a discharge port, and a safety discharge device is provided at the discharge port. The safety discharge device includes a metal connector, which is fixedly connected to the discharge port, and a discharge channel connected to the discharge port is provided in the connector , a burst disc is set in the discharge channel. The invention can better improve the subsequent sludge dehydration effect; and has the advantages of simple structure, convenient operation, high treatment efficiency and no side effects.

Owner:重庆交大国科航科技有限公司

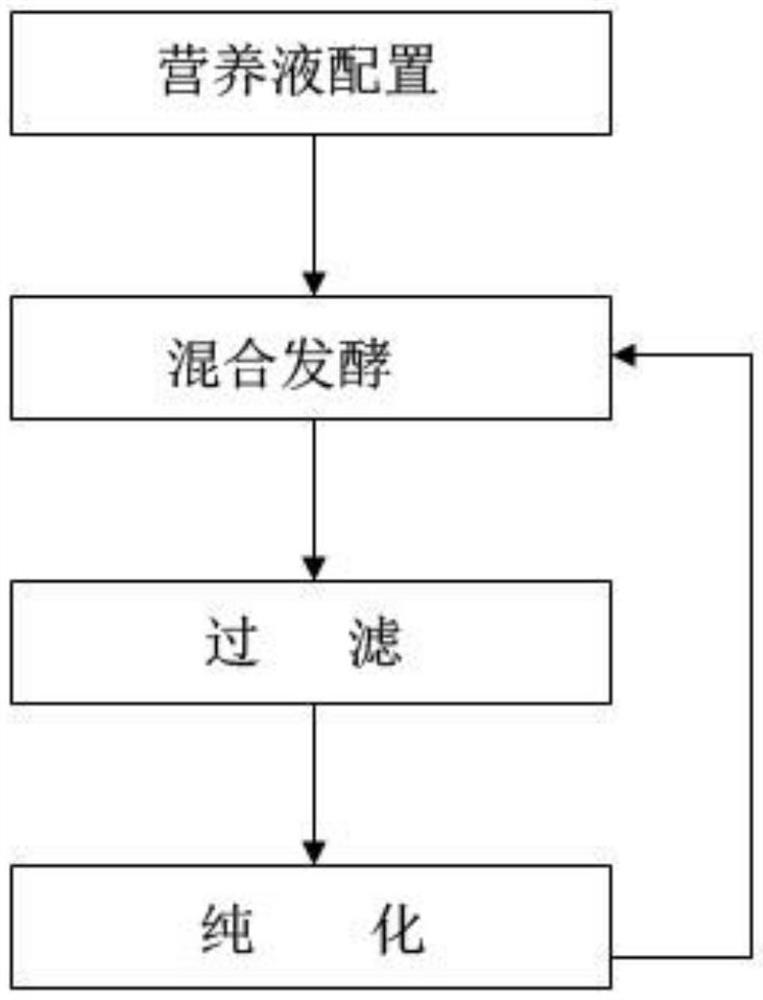

Human immune system nutrient solution based on microorganisms, and preparation method thereof

PendingCN111685314ALow costSmall side effectsFood ingredient functionsBiotechnologyBacillus subtilis var. natto

The invention relates to human immune system nutrient solution based on microorganisms. The human immune system nutrient solution is prepared from the following substances in percentage by weight: 8%-18% of bacillus subtilis, 5%-13.5% of bacillus natto, 6%-12% of bifidobacterium, 7%-15% of photosynthetic bacteria, and the balance of base solution. A preparation method of the human immune system nutrient solution comprises four steps of nutrient solution preparation, mixed fermentation, filtration and purification. On one hand, the biological activity of medicinal components and nutritional components in the raw materials is effectively improved; the purpose of rapidly recovering the physiological level and the health level of a human body is achieved; on the other hand, the biological activity and characteristics of the microorganisms are utilized; the production efficiency and the raw material utilization rate are greatly improved; meanwhile, the biological activity of the nutritionalingredients and the medicinal ingredients in raw material substances is effectively improved; and the use amount of the raw materials is effectively reduced while the purpose of conditioning nutrition of the human body is achieved.

Owner:焦作市绿色常安生物科技有限公司

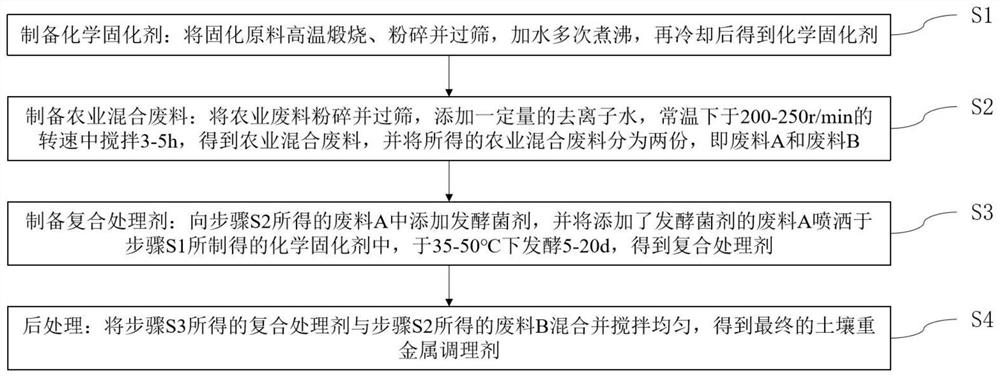

Preparation method and application of soil heavy metal conditioner

PendingCN114525138AImprove efficiencyGood effectBio-organic fraction processingContaminated soil reclamationSoil remediationSoil heavy metals

The invention belongs to the technical field of agricultural soil remediation, and particularly relates to a preparation method of a soil heavy metal conditioner, which comprises the following steps: calcining a curing raw material at high temperature, crushing, sieving, adding water, boiling for multiple times, and cooling to obtain a chemical curing agent; then, agricultural waste is smashed and sieved, water is added, the mixture is stirred at a low speed at the normal temperature, and agricultural mixed waste is obtained and divided into two parts, namely waste A and waste B; next, adding a zymophyte agent into the waste A, spraying the waste A added with the zymophyte agent into a chemical curing agent, and fermenting to obtain a composite treatment agent; and finally, mixing and uniformly stirring the composite treatment agent and the waste material B to finally obtain the soil heavy metal conditioner. The invention further provides application of the soil heavy metal conditioner. According to the method, the repairing cost is reduced, the conditioning efficiency is improved, the application range is wide, and the practicability is high.

Owner:BENGBU COLLEGE

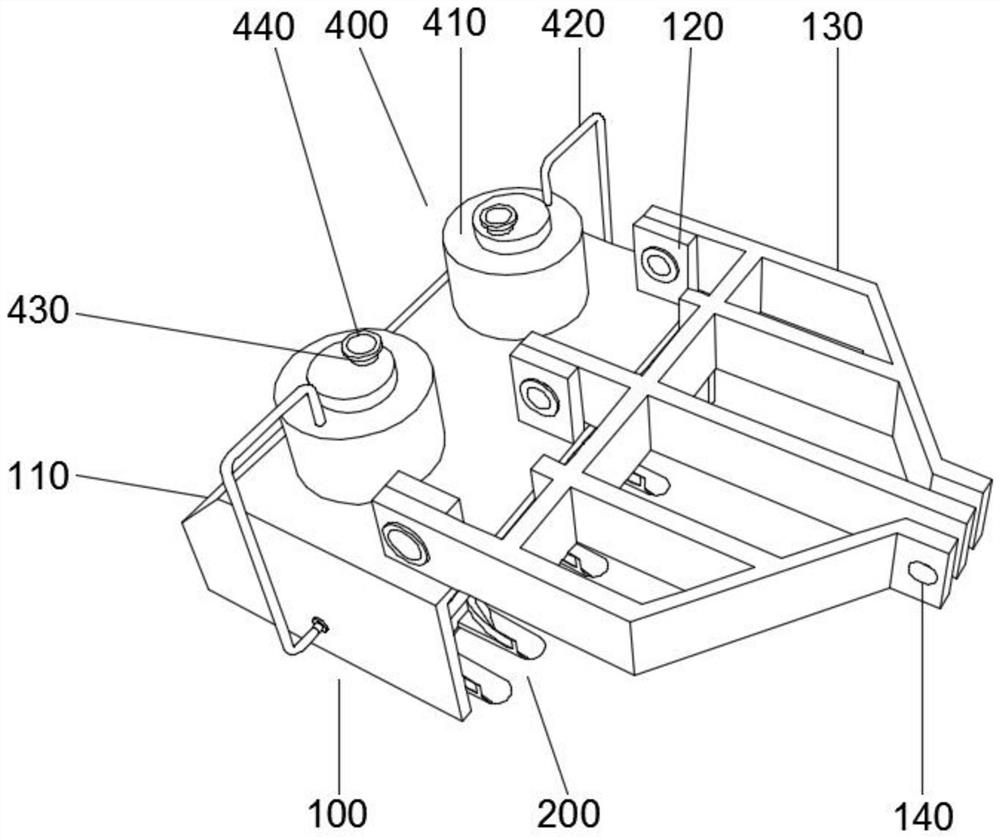

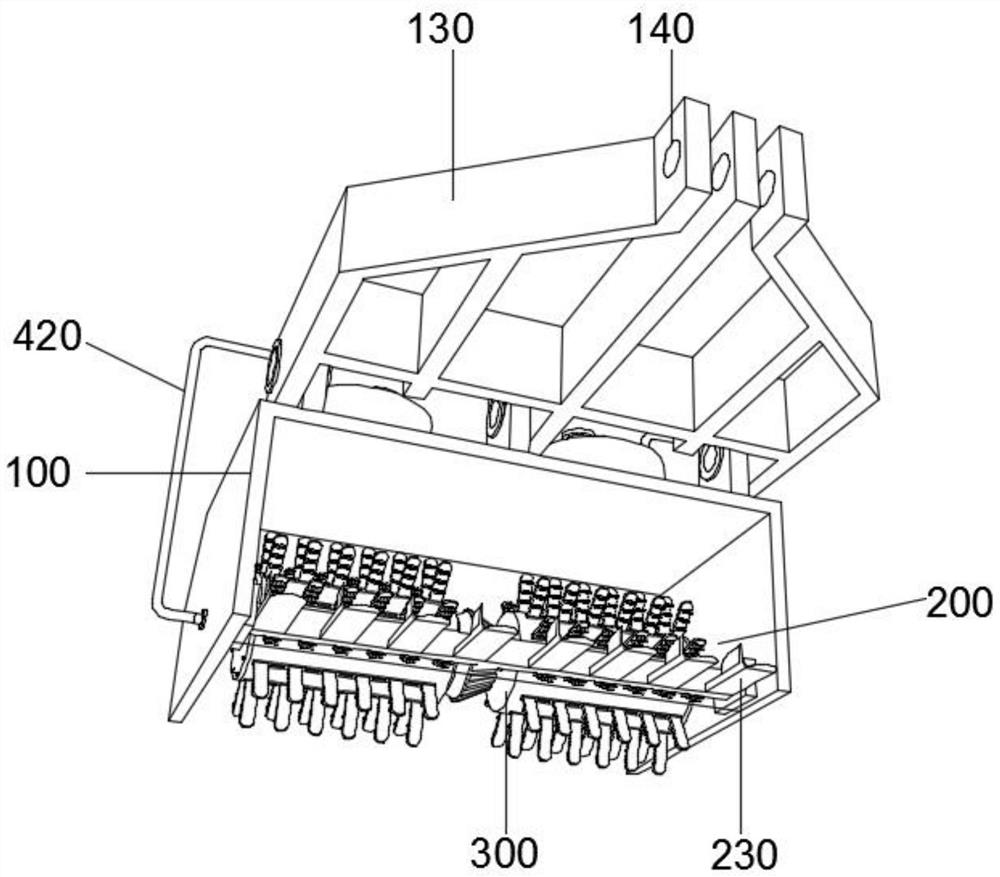

Garden waste biomass charcoal-based soil conditioning equipment and conditioning method thereof

ActiveCN114568059AImprove work efficiencyEasy to digSpadesSoil lifting machinesEnvironmental engineeringEdaphic

The invention discloses garden waste biomass charcoal-based soil conditioning equipment, and relates to the technical field of soil conditioning equipment, and the technical scheme is that the garden waste biomass charcoal-based soil conditioning equipment comprises a shell, a plowing assembly is fixedly mounted on the inner wall of the front end of the shell, two groups of soil turning rollers are rotatably connected between the inner walls of the left side and the right side of the shell, and the two groups of soil turning rollers are symmetrically arranged left and right; the soil turning roller is located behind the soil turning assembly, a biomass charcoal distribution assembly is fixedly installed at the top of the shell and comprises a liquid separation bin, the soil turning roller comprises a roller body, a first rotating shaft hole is formed in the center of the outer wall of the left end of the roller body, and a fan-shaped inserting groove is formed in the outer wall of the right end of the roller body; liquid biomass charcoal is guided into the liquid separation bin through the liquid separation pipe, and when the soil turning roller works, the liquid biomass charcoal is discharged into loosened soil through the material guide holes in the top of the soil crushing frame under the inertia effect, so that the liquid biomass charcoal uniformly permeates into the soil, and the reaction efficiency of the biomass charcoal and the soil is improved.

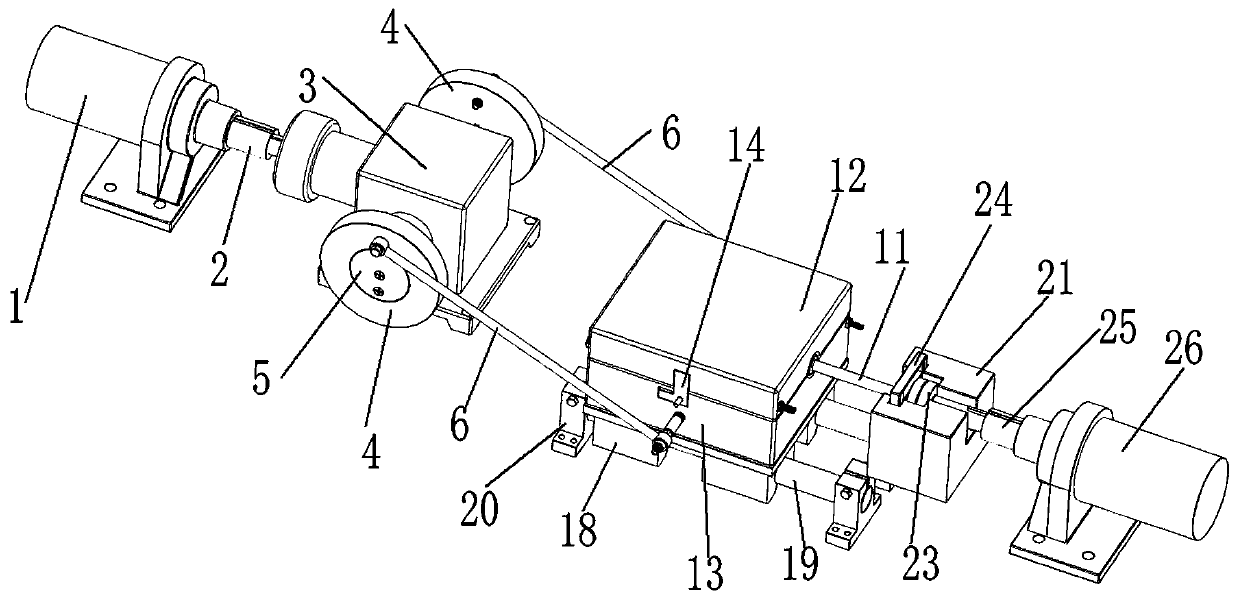

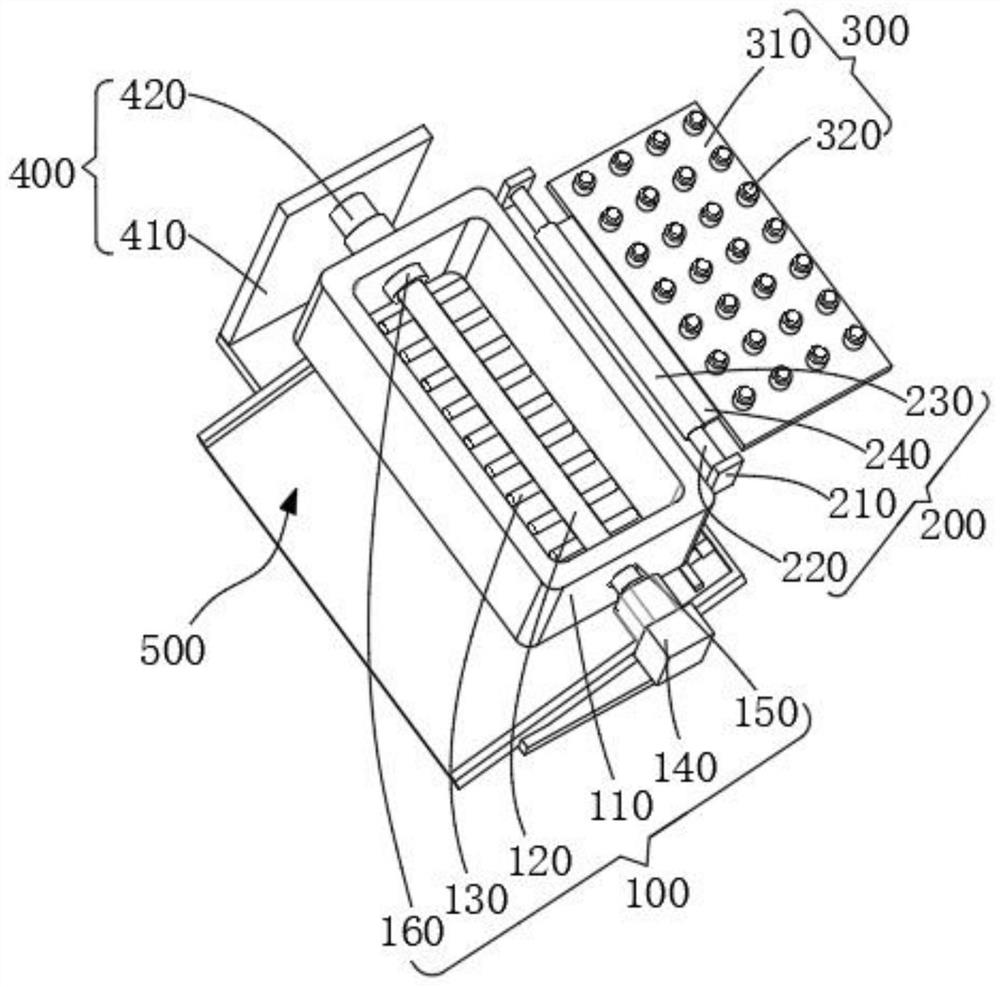

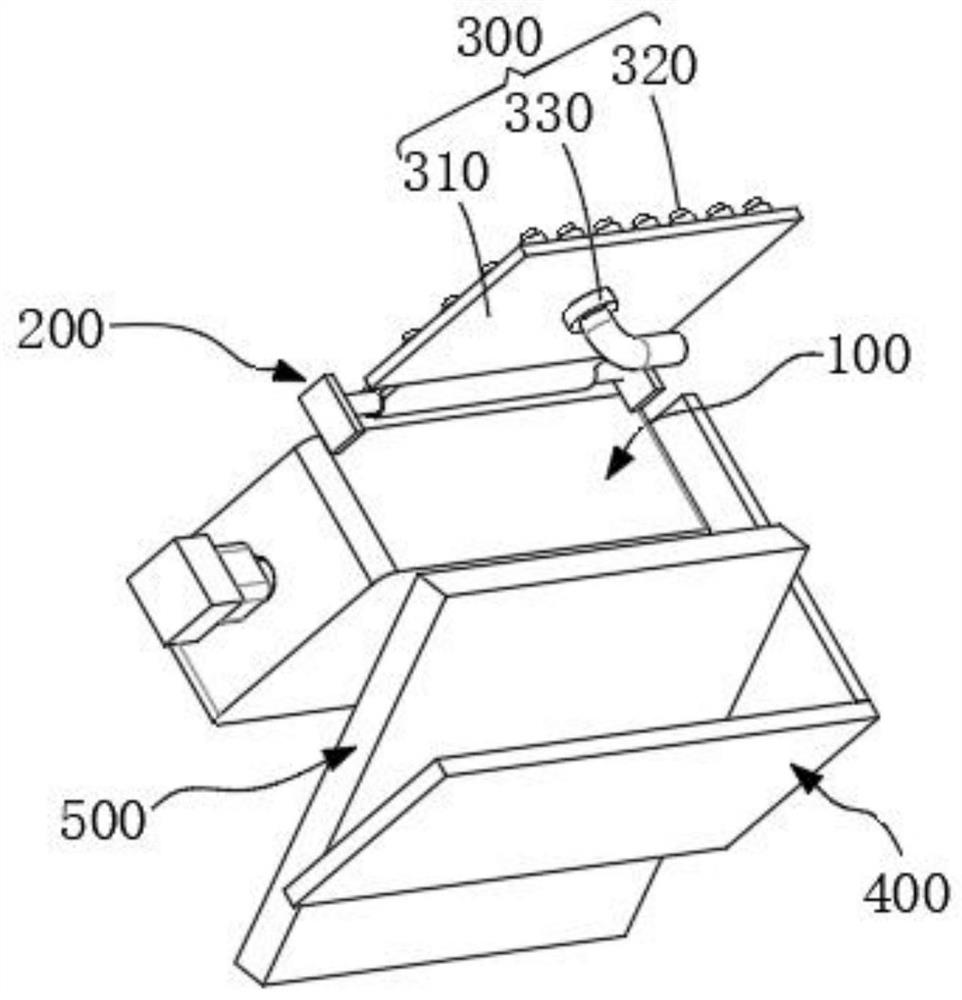

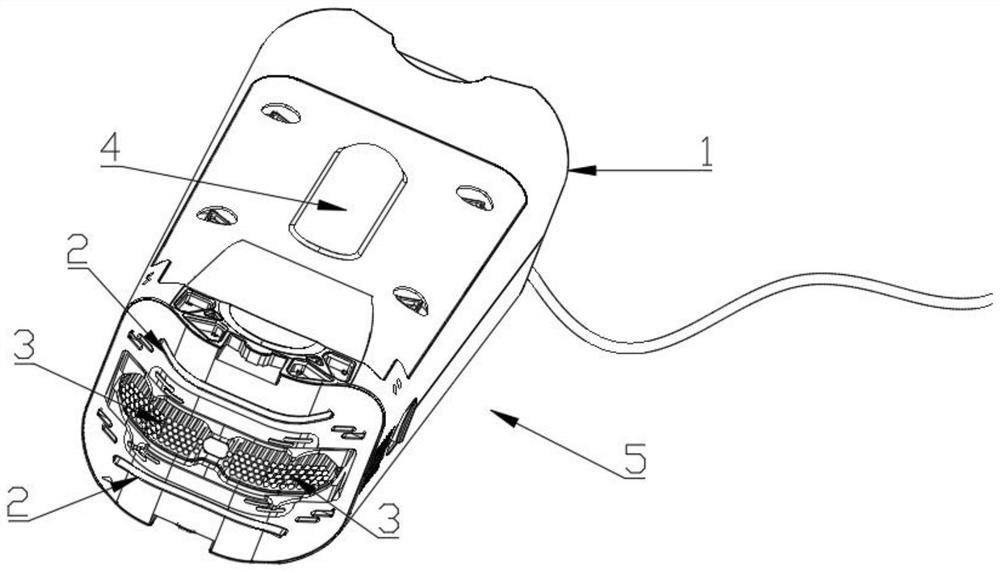

Sealant preparation tooling in the construction of the floor beam structure in the front and rear wet areas of the aircraft

ActiveCN106179068BEvenly temperedImprove conditioning efficiencyShaking/oscillating/vibrating mixersOptical axisReciprocating motion

The invention discloses a sealant modulation tempering tool for airplane front and back wet area floor beam structural construction. The tool comprises a sealant barrel fixing device, a polished shaft, a linear bearing, a fixing device, a rotating power device and a horizontal movement driving device. The linear bearing is installed on the polished shaft in a sliding mode. The sealant barrel fixing device is connected with the linear bearing. A groove is formed in the fixing device. A sealant barrel driving handle of a sealant barrel is embedded and fixed in the groove. The rotating power device is connected with the sealant barrel driving handle and used for driving the sealant barrel driving handle to rotate. The horizontal movement driving device is connected with the sealant barrel fixing device and used for driving the sealant barrel fixing device to reciprocate left and right along the polished shaft through the linear bearing. After the sealant barrel is fixed through the sealant barrel fixing device, the sealant barrel driving handle carries out rotating and stirring in the sealant barrel under the effect of the rotating power device. Under the effect of the horizontal movement driving device, the sealant barrel moves left and right relative to the sealant barrel driving handle, the sealant in the sealant barrel is uniformly tempered, and sealant tempering efficiency is improved.

Owner:SHANDONG TAIKOO AIRCRAFT ENG

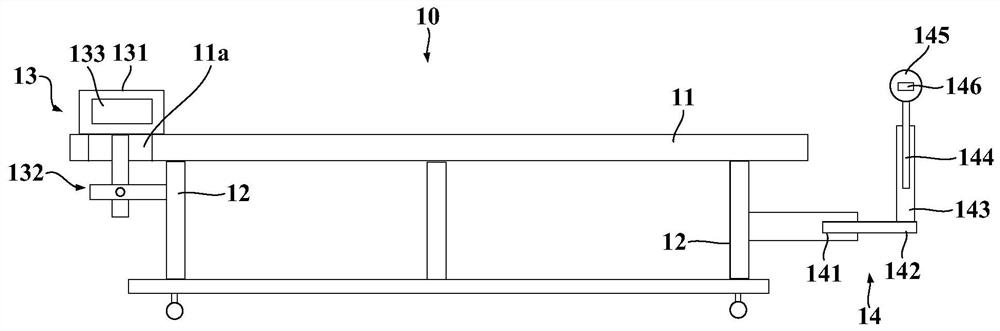

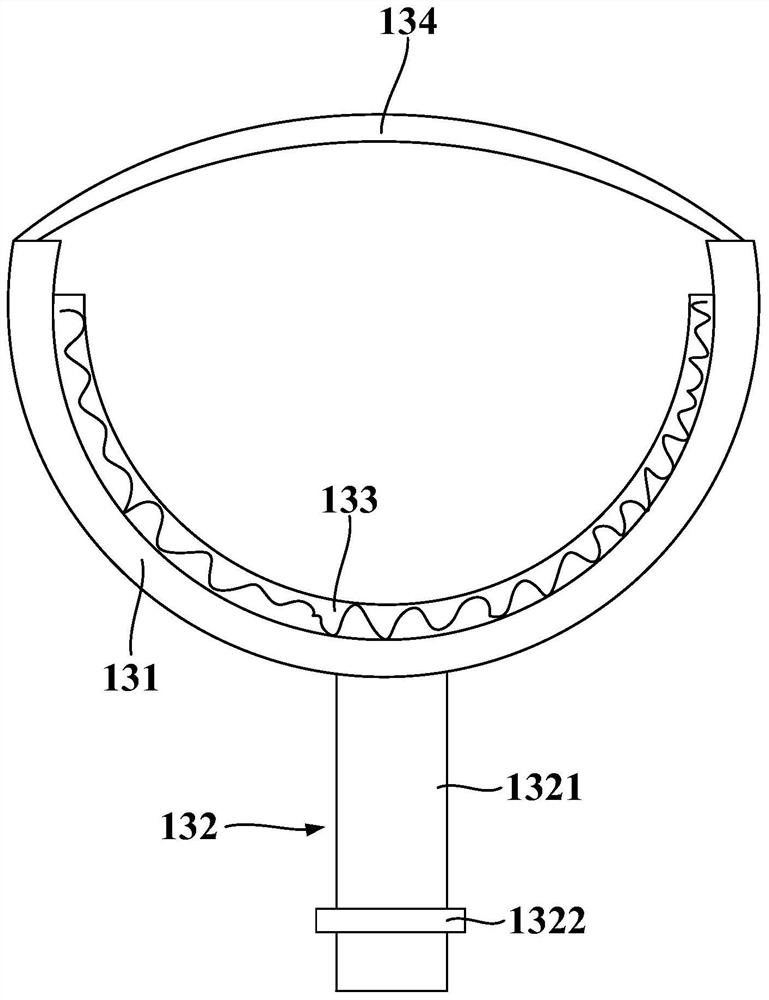

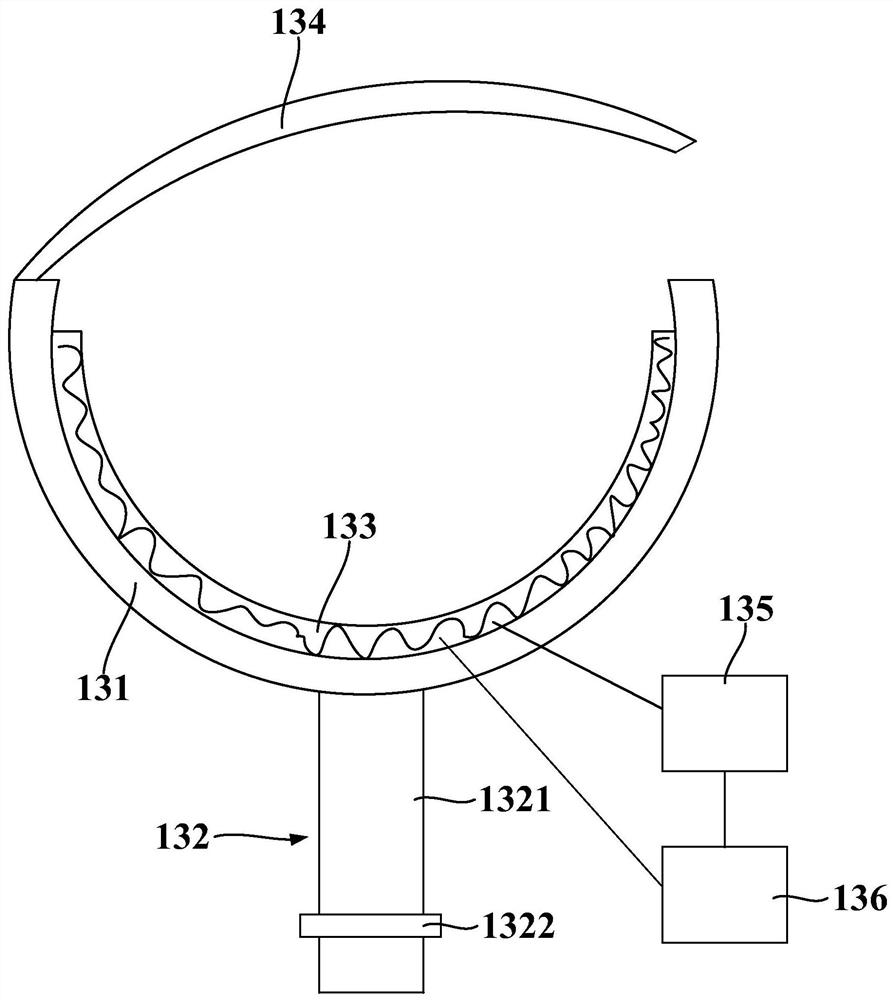

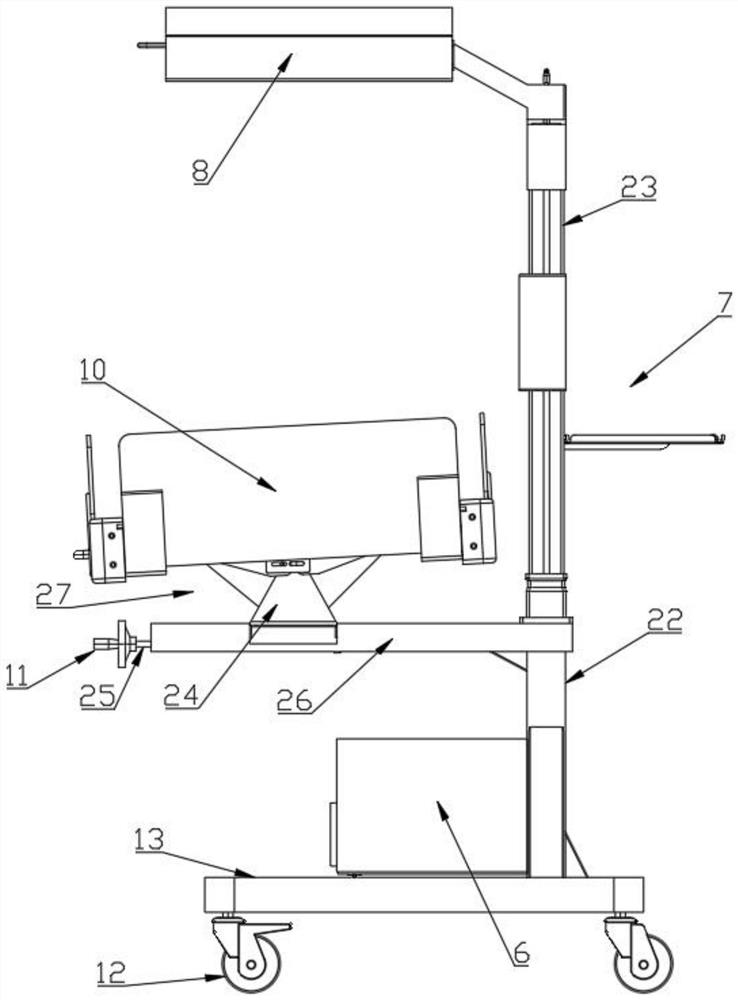

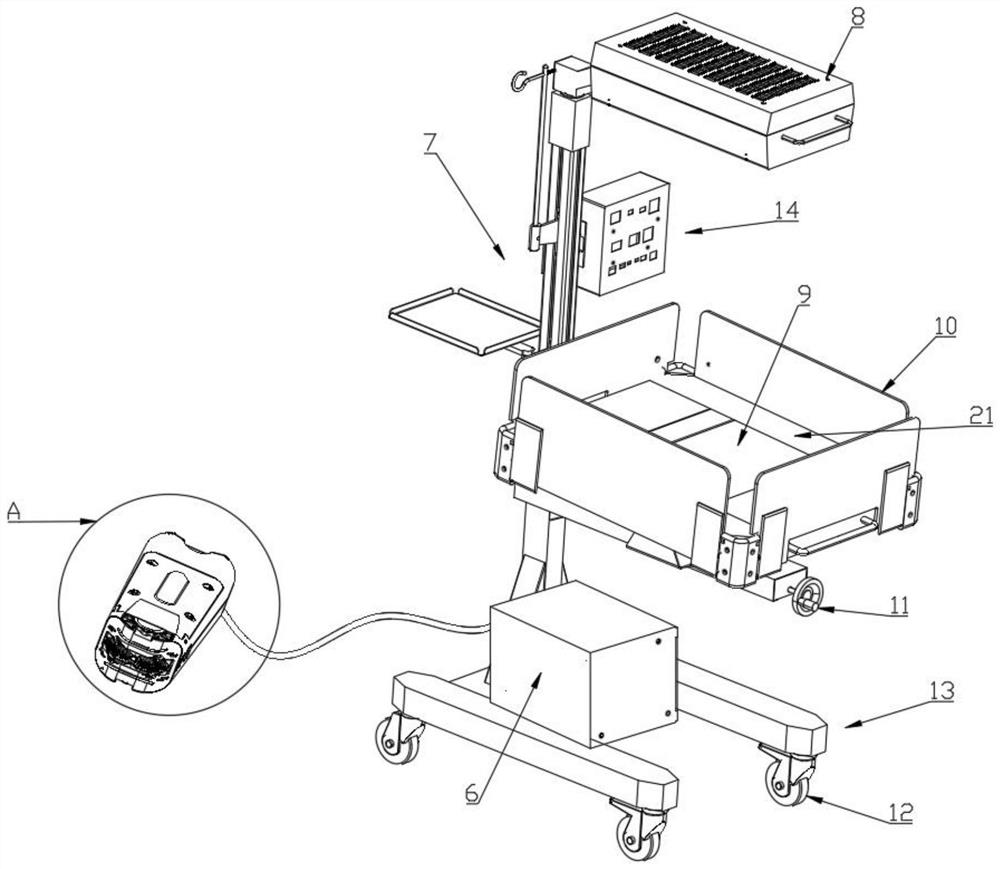

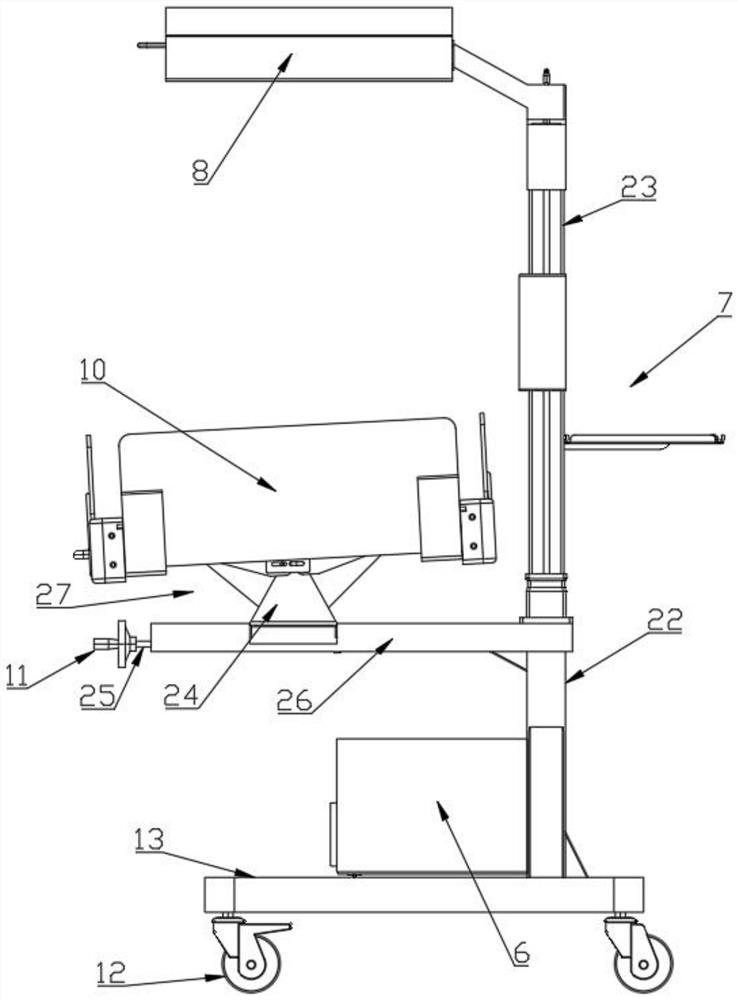

Multifunctional tendon-stretching conditioning bed

ActiveCN113520789ARelieve work fatigueWith heating functionChiropractic devicesVibration massagePhysical medicine and rehabilitationEngineering

The invention provides a multifunctional tendon-stretching conditioning bed. The bed comprises a bed board 11 and a bed frame 12 for supporting the bed board 11, wherein a headrest hole 111 is formed in the bed board 11. The multifunctional tendon-stretching conditioning bed further comprises a U-shaped neck tractor 13 used for conducting traction stretching on the neck and the cervical vertebra of a user. The U-shaped neck tractor 13 comprises: a U-shaped body 13, which is a head and neck accommodating cavity with a groove; a fixing part 132, which is arranged at the bottom of the outer side of the U-shaped body 131 and penetrates through the headrest hole 111 to be detachably connected with the bed frame 12; a heating part 133, which is arranged on the surface of the groove of the head and neck accommodating cavity; and a tightening part 134, which is arranged at the top of the U-shaped body 131 and is used for tightening the head of the user in the head and neck accommodating cavity. After the cervical vertebra of the user is stretched to a proper position through the U-shaped neck tractor 13, the U-shaped neck tractor 13 is fixed, so the cervical vertebra of the user is kept in a stretched state for a preset time length to achieve the conditioning purpose, and the working fatigue of a doctor can be relieved; and the doctor can synchronously conduct head and neck conditioning on a plurality of users, so conditioning efficiency is improved.

Owner:清叶国际健康管理北京有限公司

Efficient sludge conditioning equipment

PendingCN113354250AOptimizing high-efficiency sludge conditioning equipmentEven contactSludge treatment by de-watering/drying/thickeningRotary stirring mixersDrive motorProcess engineering

The invention discloses efficient sludge conditioning equipment which comprises a sludge conditioning and stirring assembly, a rotary connecting assembly and a conditioner feeding assembly. The sludge conditioning and stirring assembly comprises a conditioning storage frame, a rotating rod mounted in the conditioning storage frame, stirring cross rods fixed to the side faces of the periphery of the rotating rod, mounting holes formed in the side walls of the conditioning storage frame, a driving motor passing through the mounting hole and connected with the stirring cross rods, and a fixed sleeve fixed on the inner side wall of the conditioning storage frame and connected with the stirring cross rods in a sleeving manner. Traditional efficient sludge conditioning equipment is optimized. Through mutual cooperation of the rotary connecting structure and the conditioner feeding structure, the effect that sludge is fully covered by a fed conditioner is achieved, the fed conditioner fully covers the sludge while stirring is conducted, the conditioner makes contact with the sludge more uniformly, the stirring time is shortened, and the sludge conditioning efficiency is improved.

Owner:杭州国泰环保科技股份有限公司

Biochemical sludge conditioning equipment

ActiveCN108545901ADoes not change chemical compositionDoes not change performanceSludge treatment by de-watering/drying/thickeningBiological sludge treatmentBiochemical engineeringProduct gas

The invention discloses biochemical sludge conditioning equipment. The equipment is characterized by comprising a pressure sludge storage tank; the pressure sludge storage tank is provided with a sludge feeding opening with a sealing opening and closing cover; the pressure sludge storage tank is also provided with a high-pressure gas inlet; a high-pressure gas pipe communicates with the external part of the high-pressure gas inlet; a gas pipe switching valve is arranged on the high-pressure gas pipe; a high-pressure gas adding device is arranged at one end, far away from the pressure sludge storage tank, of the high-pressure gas pipe; the pressure sludge storage tank is also provided with a release opening; a safe release device is arranged at the release opening; the safe release device comprises a metal connecting head; the connecting head is fixedly connected at the release opening; a release channel communicating with the release opening is arranged in the connecting head; and a rupture disk is arranged in the release channel. With the equipment provided by the invention, the subsequent dehydration effect of the sludge can be better improved, and the equipment has the advantages of simple structure, convenient operation, high processing efficiency, no side effect and the like.

Owner:重庆交大国科航科技有限公司

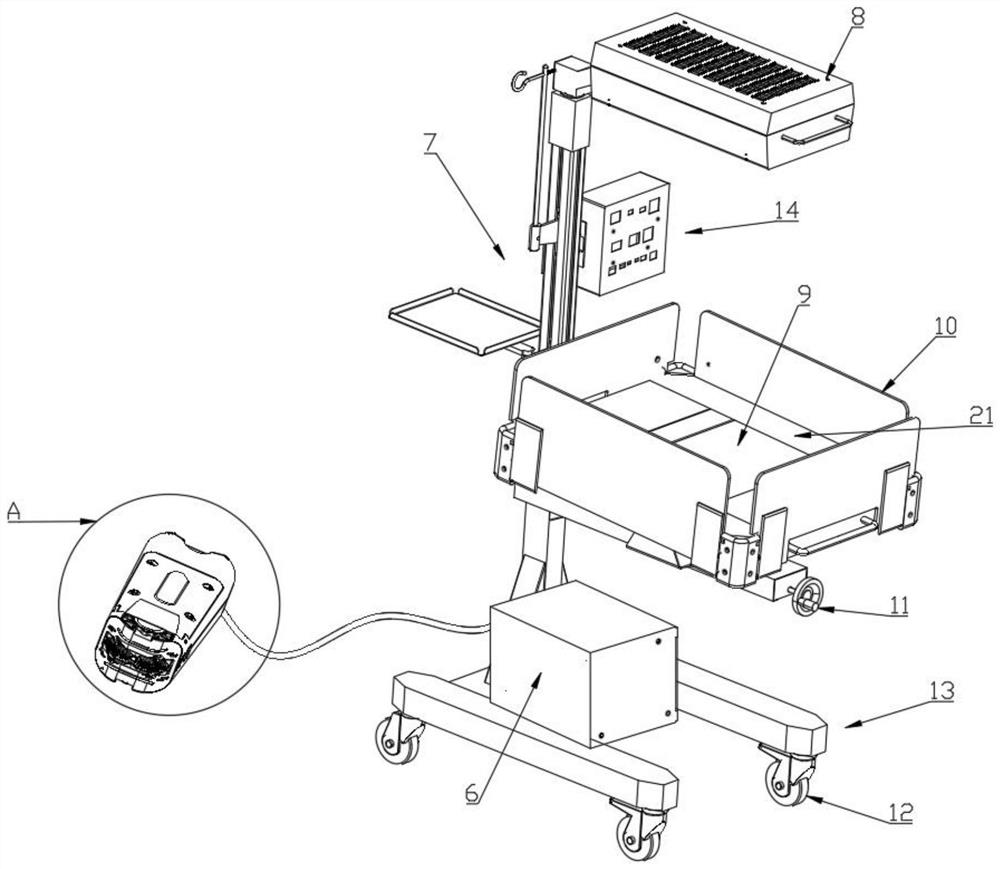

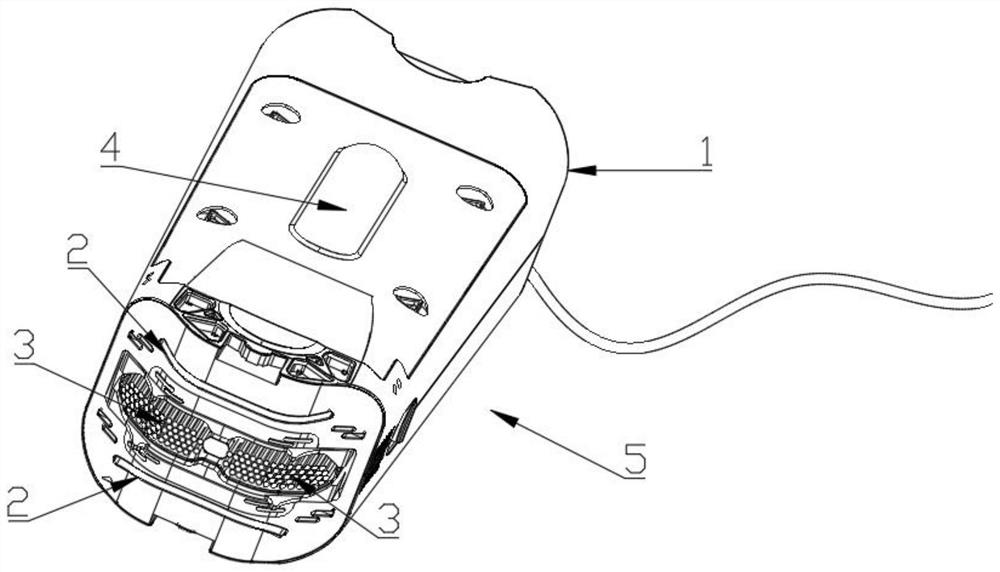

Skin icterus tester for pediatric department

ActiveCN111714780AImprove conditioning efficiencyImprove collaborative work efficiencyLight therapyEmergency medicineIntensive care medicine

The invention provides a skin icterus tester for the pediatric department. The skin icterus tester for the pediatric department comprises a sampling device, an analysis device, a conditioning device and a controller, wherein the sampling device is configured to carry out sampling on a sampling part, and the analysis device is configured to analyze according to a sampled specimen and feed back a diagnosis result to the conditioning device; the conditioning device is configured to perform conditioning operation based on results of the sampling device and the analysis device; and the sampling device, the analysis device and the conditioning device are in control connection with the controller respectively. After the analysis device is adopted to analyze with an operator, a conditioning list is generated based on rules according to opinions of the operator, and the list guides the conditioning device to perform operation in subsequent conditioning, so that the workload of operation is greatly reduced, a communication barrier between conditioning equipment and analysis equipment is reduced, and the conditioning efficiency is greatly improved.

Owner:冯孝强

A Pediatric Percutaneous Jaundice Apparatus

ActiveCN111714780BImprove conditioning efficiencyImprove collaborative work efficiencyLight therapyPhysical medicine and rehabilitationPhysical therapy

The invention provides a pediatric percutaneous jaundice instrument, comprising a sampling device, an analysis device, a conditioning device and a controller, the sampling device is configured to sample the sampling site, and the analysis device is configured to perform Analyze and feed back to the conditioning device according to the diagnosis results; the conditioning device is configured to perform conditioning operations based on the results of the sampling device and the analysis device; the sampling device, the analysis device and the conditioning device are respectively connected with The controller controls connections. After analyzing with the operator by the analysis device, a list of adjustments is generated based on the operator's opinion and based on the rules, and the list guides the adjustment device to perform in the subsequent adjustments. The operation greatly reduces the workload of the operation, lowers the communication barrier between the conditioning equipment and the analysis equipment, and greatly improves the conditioning efficiency.

Owner:冯孝强

Sealant modulation tempering tool for airplane front and back wet area floor beam structural construction

ActiveCN106179068AThe sealant is evenly temperedImprove efficiencyShaking/oscillating/vibrating mixersAirplaneEngineering

The invention discloses a sealant modulation tempering tool for airplane front and back wet area floor beam structural construction. The tool comprises a sealant barrel fixing device, a polished shaft, a linear bearing, a fixing device, a rotating power device and a horizontal movement driving device. The linear bearing is installed on the polished shaft in a sliding mode. The sealant barrel fixing device is connected with the linear bearing. A groove is formed in the fixing device. A sealant barrel driving handle of a sealant barrel is embedded and fixed in the groove. The rotating power device is connected with the sealant barrel driving handle and used for driving the sealant barrel driving handle to rotate. The horizontal movement driving device is connected with the sealant barrel fixing device and used for driving the sealant barrel fixing device to reciprocate left and right along the polished shaft through the linear bearing. After the sealant barrel is fixed through the sealant barrel fixing device, the sealant barrel driving handle carries out rotating and stirring in the sealant barrel under the effect of the rotating power device. Under the effect of the horizontal movement driving device, the sealant barrel moves left and right relative to the sealant barrel driving handle, the sealant in the sealant barrel is uniformly tempered, and sealant tempering efficiency is improved.

Owner:SHANDONG TAIKOO AIRCRAFT ENG

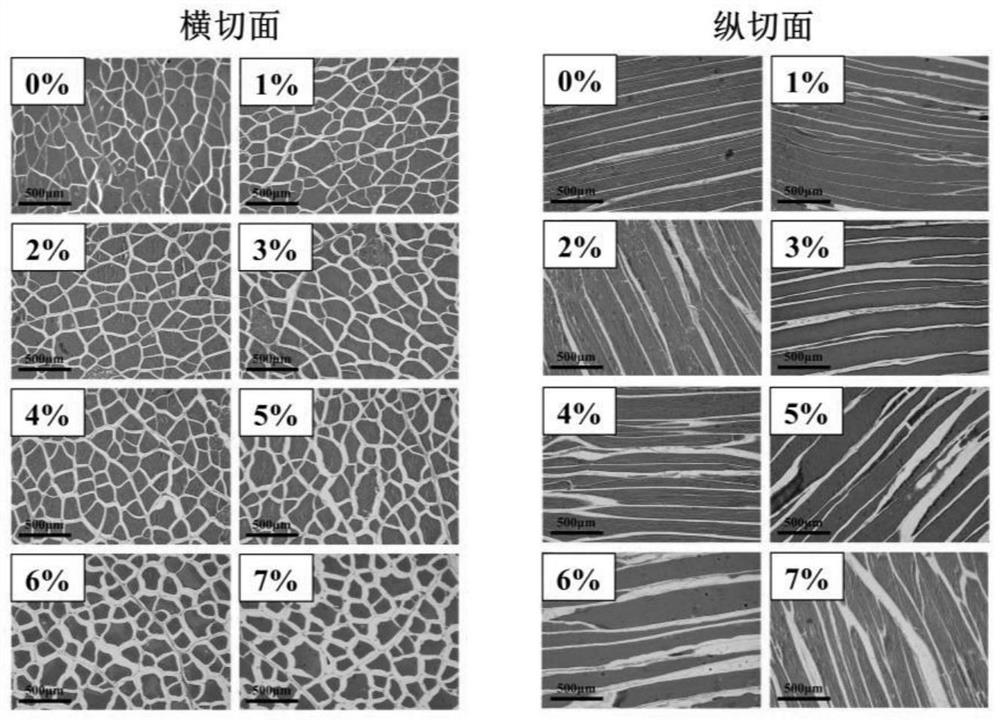

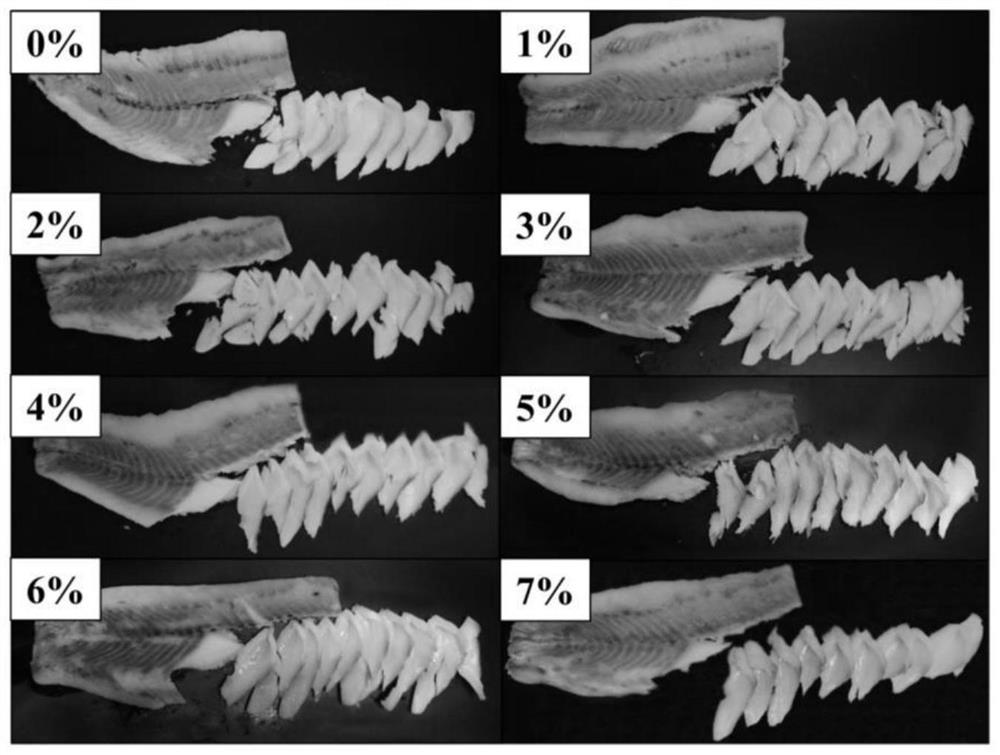

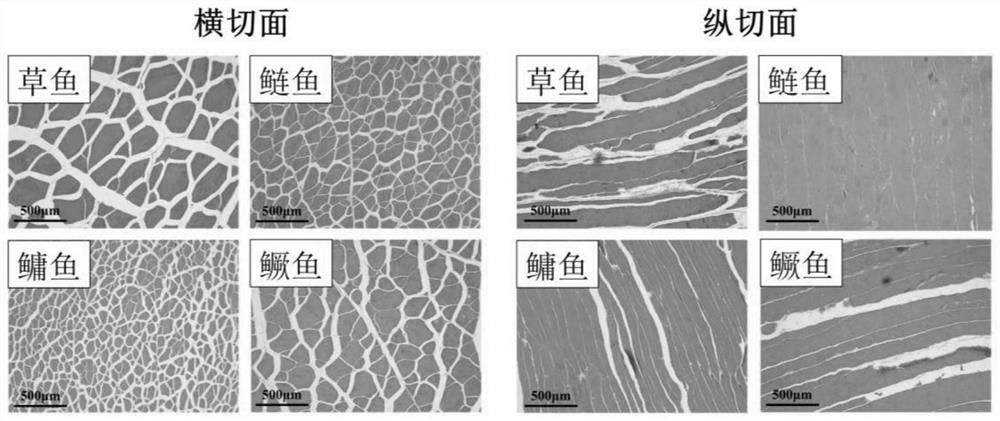

Method for promoting formation of fish meat and garlic clove meat based on gradient vacuum conditioning and application

ActiveCN114794407AImprove textural propertiesEnhance savory tasteFood freezingClimate change adaptationBiotechnologyAnimal science

The invention discloses a method for promoting formation of'garlic clove meat 'of fish meat based on gradient vacuum conditioning and application, and belongs to the technical field of aquatic product processing. The method comprises the following specific steps: pretreating freshwater fish; applying table salt; performing vacuum conditioning; performing vacuum packaging; standing and conditioning; and freezing and preserving after liquid nitrogen freezing. According to the technical scheme, the prepared conditioned fish product with the garlic clove meat structure is simple and effective, and the permeation rate of salt is promoted, so that the time of the whole conditioning stage is effectively shortened; by adopting the technology, the release of calcium ions in the conditioned fish meat can be promoted, so that calcium-excited protease is activated, the calcium-excited protease shows relatively high enzyme activity, myofibrillar protein is degraded, Z lines in muscle fibers are destroyed, the generation of a garlic clove meat structure of the conditioned fish product is promoted, the internal structure of the fish meat is improved, and the texture of the product is further influenced; according to the invention, various freshwater fishes can form a garlic clove meat structure, and the sensory quality of fish meat is good.

Owner:HUAZHONG AGRI UNIV

A sludge conditioning device

ActiveCN110183093BReduce the stress of deep dehydrationIncrease the speed of temperingRotating receptacle mixersSludge treatment by de-watering/drying/thickeningSludgeProcess engineering

The present invention relates to the field of sludge treatment equipment, in particular to a sludge conditioning device, which includes a feeding screw conveyor, a transport mechanism and a discharge screw conveyor. The transport mechanism includes a driving component, a feeding component, a transport component, a transmission component and several mixing components, the driving component is installed on one side of the transport component and the two are connected by transmission, the feeding component is set on the upper end of the transport component, the transmission component is set on the other end of the transport component, and several stirring components are in the form of a circle Distributed in the transport component, and each mixing component is connected to the transport component through a transmission component, and a receiving component is arranged directly under the transport component. When the present invention is in use, it can continue to work, thereby improving the efficiency of sludge conditioning, and can filter out the separated sewage during the conditioning process, reducing the workload of subsequent sludge dehydration. The present invention It can also reduce the working intensity of the equipment and prolong the service life.

Owner:深圳市鸿卓环保科技有限公司

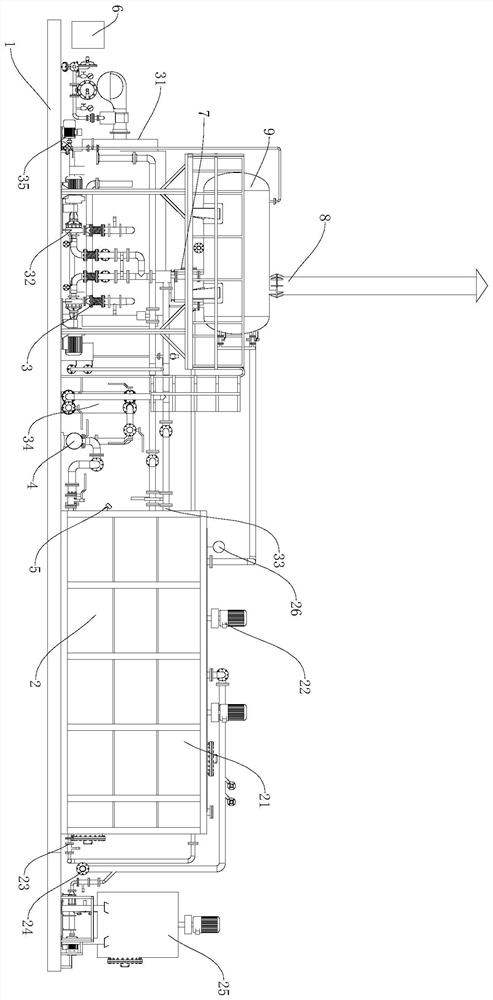

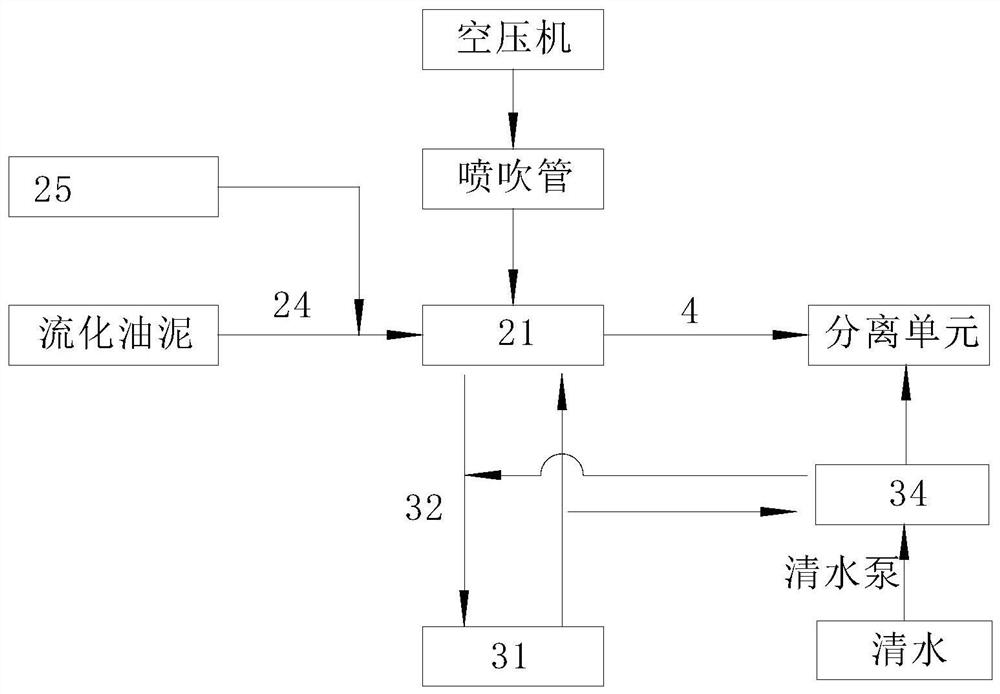

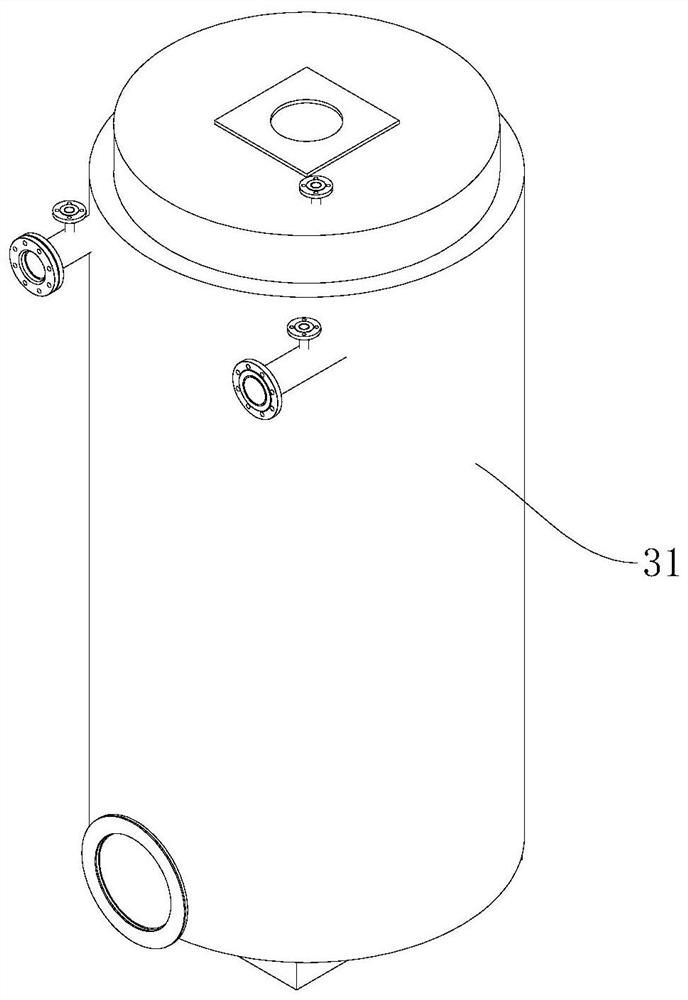

Integrated oil sludge conditioning device and use method thereof

PendingCN112851061AImprove work efficiencyImprove conditioning efficiencyWaste water treatment from quariesSludge treatmentTemperingProcess engineering

The invention provides an integrated oil sludge conditioning device and a use method thereof, relates to the technical field of oil sludge processing, mainly aims at solving the problem that traditional oil sludge conditioning equipment is difficult to demount, and provides integrated oil sludge conditioning equipment which is high in equipment integration level, easy to transfer and relatively high in conditioning efficiency. The integrated oil sludge conditioning device comprises a skid seat, a conditioning unit, a heat supply unit and an efflux pump, wherein the conditioning unit, the heat supply unit and the efflux pump are fixedly mounted on the upper surface of the skid seat; a cavity for containing materials is formed in the hardening and tempering unit, and the heat supply unit is partially located in the hardening and tempering unit and can heat the materials contained in the hardening and tempering unit; the hardening and tempering unit is communicated with the output pump, and when the hardening and tempering unit reaches the output temperature, materials in the hardening and tempering unit can be conveyed into the next stage of separation equipment through the output pump and are subjected to oil, mud and water three-phase separation.

Owner:LANGFANG DEV ZONE FANHUA PETRIFACTION MACHINERY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com