Conditioning and granulating integrated apparatus

A conditioning and preheating device technology, applied in the direction of feed, food science, application, etc., can solve the problems of low efficiency, long conditioning and granulation time, large power consumption, etc., to achieve good heat transfer, high efficiency, and improved The effect of mixing and tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

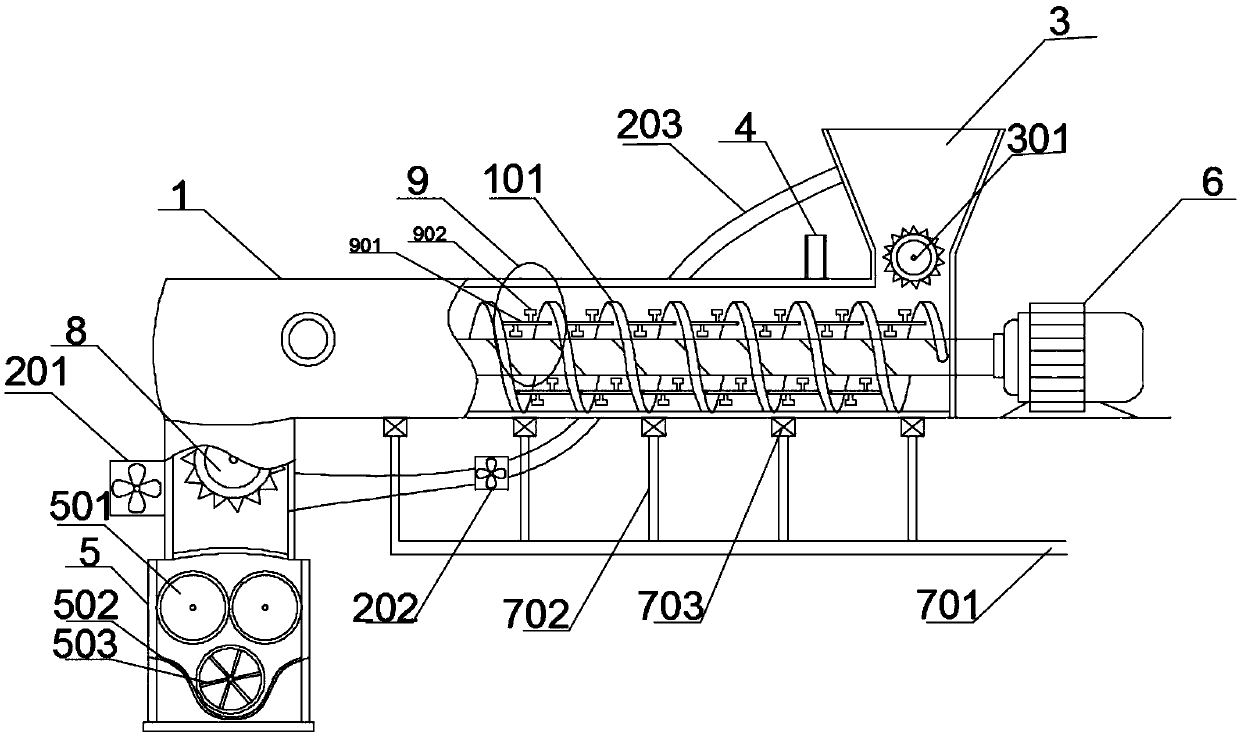

[0033] Such as figure 1As shown, this embodiment provides an integrated device for tempering and granulation, including a conditioning part and a granulating device 5, the conditioning part includes a conditioning cylinder 1, an auger device and a steam device, and the top of one end of the conditioning cylinder 1 A hopper 3 is provided, a discharge port is provided under the other end of the tempering cylinder 1, a granulation device 5 is fixedly connected to the discharge port, a steam device is provided under the conditioning cylinder 1, and a preheating device and an intensified stirring device are also included 9. The preheating device includes a blower 201, an exhaust fan 202 and a ventilation pipe 203, and the strengthening stirring device 9 includes a fixed connecting rod 901 horizontally fixed on the auger device and a T-shaped stirring plate 902 arranged on the fixed connecting rod 901, The auger device is also provided with a guide strip 101; the top of the conditio...

Embodiment 2

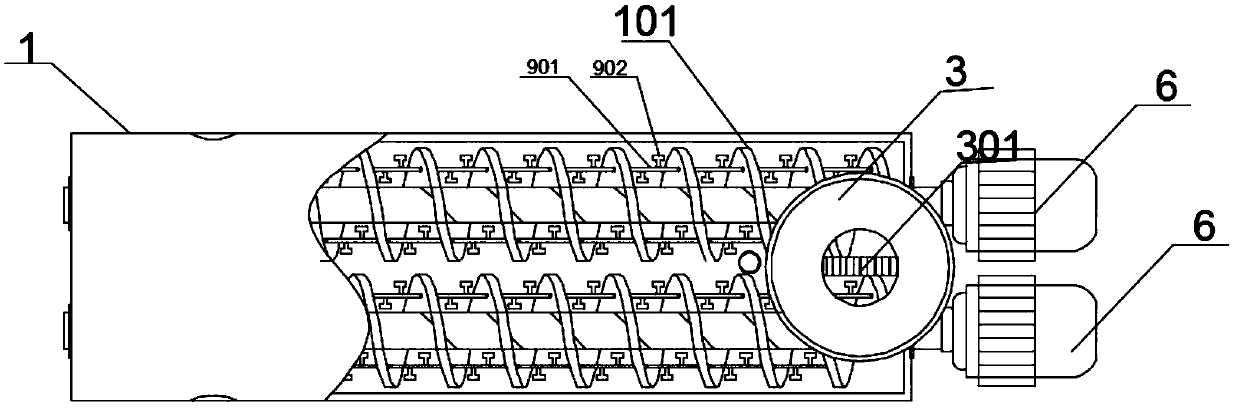

[0046] Such as figure 1 and figure 2 As shown, further improvements were made on the basis of Example 1 to achieve further optimization of the performance of the integrated conditioning and granulation device. Specifically, two sets of auger devices are arranged side by side in the conditioning cylinder 1 . Compared with Example 1, the two groups of auger devices rotate in opposite directions, which enhances the friction between stirring and various raw materials of the feed, and promotes fermentation and aging.

Embodiment 3

[0048] Such as figure 1 and figure 2 As shown, further improvements were made on the basis of Example 2 to further optimize the performance of the integrated conditioning and granulation device. A stirring wheel 1 301 is provided between the hopper 3 and the conditioning cylinder 1 . The transferred feed materials may be agglomerated before being fed, and the contacted feed materials can be quickly dispersed by the rotation of the stirring wheel-301, which is convenient for the conditioning process. Compared with Example 2, adding a stirring wheel 1 301 can speed up the cooling speed of the conditioned feed material, and can shorten the length of the discharge opening structurally, or reduce the working power of the blower 201, so as to achieve the purpose of energy saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com