Component tempering material suitable for blast furnace slag glass-ceramic and its tempering method

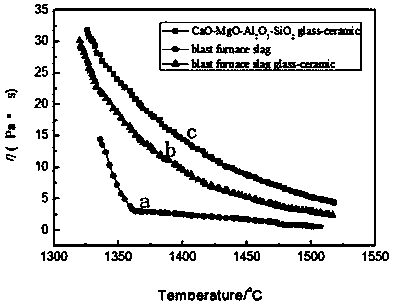

A technology of blast furnace slag and glass-ceramics, which is applied in the field of glass-ceramics preparation, can solve problems such as the difficulty in crystallization control of glass-ceramics and the negative impact on the mechanical properties of glass-ceramics plates, and achieves simple and easy control of the implementation process and improved Effect of improving mechanical properties, viscosity characteristics and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A component conditioning material suitable for blast furnace slag glass-ceramics, the composition of which includes: 22 parts of quartz sand, 5 parts of calcium sulfate, 4 parts of talcum powder, 2 parts of barium carbonate, 6 parts of albite powder, fluorine 3 parts of sodium silicate, 3 parts of phosphorus pentoxide, 1 part of float glass powder.

[0033] The blast furnace slag is used as the main raw material to prepare glass-ceramics, and the blast furnace slag is tempered with the above-mentioned tempering material. The process of the tempering method is as follows:

[0034] (1) In terms of parts by mass, weigh 54 parts of blast furnace slag; and weigh 54 parts of the composition conditioning material. 6 parts of stone powder, 3 parts of sodium fluorosilicate, 3 parts of phosphorus pentoxide, 1 part of float glass powder;

[0035] 2) The accurately weighed composition conditioning material is ground in a ball mill, mixed evenly, placed in a crucible, melted in a h...

Embodiment 2

[0040] A component conditioning material suitable for blast furnace slag glass-ceramics, the composition of which includes: 6 parts of quartz sand, 3 parts of calcium sulfate, 2 parts of talcum powder, 0.5 parts of barium carbonate, 3.5 parts of albite powder, fluorine 2 parts of sodium silicate, 1 part of phosphorus pentoxide, 3 parts of float glass powder.

[0041] The blast furnace slag is used as the main raw material to prepare glass-ceramics, and the blast furnace slag is tempered with the above-mentioned tempering material. The process of the tempering method is as follows:

[0042] (1) In terms of parts by mass, weigh 79 parts of blast furnace slag; and weigh 79 parts of the composition conditioning material. 3.5 parts of stone powder, 2 parts of sodium fluorosilicate, 1 part of phosphorus pentoxide, 3 parts of float glass powder;

[0043] 2) The accurately weighed composition conditioning material is ground in a ball mill, mixed evenly, placed in a crucible, melted i...

Embodiment 3

[0048] A component conditioning material suitable for blast furnace slag glass-ceramics, the composition of which includes: 15 parts of quartz sand, 4 parts of calcium sulfate, 8 parts of talcum powder, 1 part of barium carbonate, 4 parts of albite powder, fluorine 4 parts of sodium silicate, 2 parts of phosphorus pentoxide, 4 parts of float glass powder.

[0049] The blast furnace slag is used as the main raw material to prepare glass-ceramics, and the blast furnace slag is tempered with the above-mentioned tempering material. The process of the tempering method is as follows:

[0050] (1) In terms of parts by mass, weigh 58 parts of blast furnace slag; and weigh 58 parts of the composition conditioning material. 4 parts of stone powder, 4 parts of sodium fluorosilicate, 2 parts of phosphorus pentoxide, 4 parts of float glass powder;

[0051] 2) The accurately weighed composition conditioning material is ground in a ball mill, mixed evenly, placed in a crucible, melted in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com