Combined sludge conditioning tank and continuous sludge conditioning process

A sludge conditioning and combined technology, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, water/sewage treatment, etc., can solve the problem of large volume, high cost and long conditioning time of the conditioning tank and other problems, to achieve the effect of short conditioning time, low cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

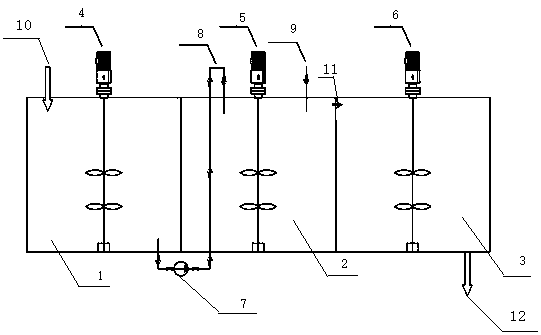

[0020] refer to figure 1 , the combined sludge conditioning tank in this embodiment includes a buffer tank 1, a sludge mixing tank 2 and a homogenization tank 3, and the buffer tank 1, the mud mixing tank 2 and the homogenization tank 3 adopt a common wall design; the buffer tank 1 The upper part of the buffer tank is provided with a sludge inlet 10, and the bottom of the buffer tank is provided with a sludge delivery pipeline 8 with a sludge delivery pump 7 to communicate with the upper part of the mud medicine mixing tank 2; the top of the mud medicine mixing tank 2 is provided with a belt The drug delivery pipeline 9 of the drug delivery pump, the upper part of the mud medicine mixing tank 2 and the upper part of the homogenization tank 3 are provided with passages, that is, the gap 11 on the common wall of the upper part of the mud medicine mixing tank 2 and the upper part of the homogenization tank 3 communicates with each other , the bottom of the homogenization tank 3 i...

Embodiment 2

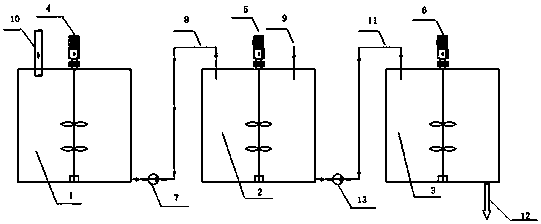

[0023] refer to figure 2 , the combined sludge conditioning tank in this embodiment includes a buffer tank 1, a sludge mixing tank 2 and a homogenization tank 3, and the buffer tank 1, the mud mixing tank 2, and the homogenization tank 3 are designed separately; the buffer tank 1 The upper part is provided with a sludge inlet 10, and the bottom of the buffer tank is provided with a sludge delivery pipeline 8 with a sludge delivery pump 7 to communicate with the upper part of the mud medicine mixing tank 2; the top of the mud medicine mixing tank 2 is provided with a The medicament delivery pipeline 9 of the delivery pump, the sludge delivery pipeline 11 with the sludge delivery pump 13 is provided in the lower part of the mud medicine mixing tank 2 to communicate with the upper part of the homogenization tank 3, and the lower part of the homogenization tank 3 is provided with There is a sludge outlet 12; the buffer tank 1, the mud medicine mixing tank 2 and the homogenization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com