Preparation method and application of soil heavy metal conditioner

A technology for heavy metals and conditioners, applied in the field of agricultural soil remediation, can solve the problems of single action, the removal rate of heavy metals needs to be further improved, and the scope of application is narrow, and achieves the effects of strong practicability, enhanced efficiency and effect, and reduced remediation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

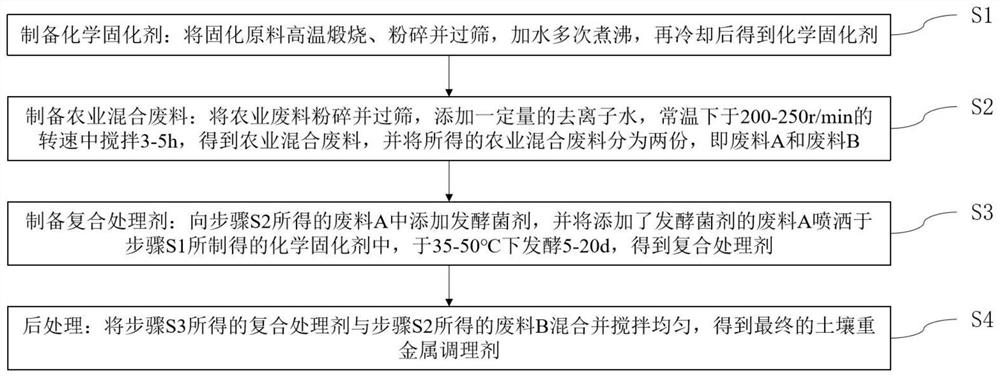

[0023] A preparation method of a soil heavy metal conditioner, comprising the following steps:

[0024] Step S1: Preparation of chemical curing agent: calcining, pulverizing and sieving (100 mesh) the solidified raw materials at high temperature, adding water and boiling for 3 times, and each boiling time is 1 hour, and then cooling to obtain a chemical curing agent with a water content of 30% . In this embodiment, the solidified raw material is fly ash.

[0025] Step S2: Preparation of agricultural mixed waste: pulverize and sieve the agricultural waste, add a certain amount of deionized water, stir at a rotation speed of 200 r / min at room temperature for 3 hours, and obtain the agricultural mixed waste with a water content of 70%, and the obtained The agricultural mixed waste is divided into two parts, namely waste A and waste B. In this embodiment, the agricultural waste is straw.

[0026] Step S3: preparing a composite treatment agent: adding a fermentation inoculum to ...

specific Embodiment 2

[0028] A preparation method of a soil heavy metal conditioner, comprising the following steps:

[0029] Step S1: Preparation of chemical curing agent: calcining, pulverizing and sieving (100 mesh) the solidified raw materials at high temperature, adding water and boiling for 6 times, and each boiling time is 2 hours, and then cooling to obtain a chemical curing agent with a water content of 45% . In this example, the solidified raw material is a mixture of complex phosphate and diatomaceous earth.

[0030] Step S2: Preparation of agricultural mixed waste: pulverize and sieve the agricultural waste, add a certain amount of deionized water, stir at a rotation speed of 250 r / min at room temperature for 5 hours, and obtain an agricultural mixed waste with a water content of 80%, and the obtained The agricultural mixed waste is divided into two parts, namely waste A and waste B. The agricultural waste in this example is a mixture of wood chips and bran.

[0031] Step S3: prepari...

specific Embodiment 3

[0033] A preparation method of a soil heavy metal conditioner, comprising the following steps:

[0034] Step S1: Preparation of chemical curing agent: calcining, pulverizing and sieving (100 mesh) the solidified raw materials at high temperature, adding water and boiling for 4 times, and each boiling time is 2 hours, and then cooling to obtain a chemical curing agent with a water content of 35% . In this embodiment, the curing raw material is composite phosphate.

[0035] Step S2: Preparation of agricultural mixed waste: pulverize and sieve the agricultural waste, add a certain amount of deionized water, stir at a rotation speed of 230 r / min at room temperature for 4 hours, and obtain agricultural mixed waste with a water content of 75%, and the obtained The agricultural mixed waste is divided into two parts, namely waste A and waste B. In this embodiment, the agricultural waste is livestock manure.

[0036] Step S3: preparing a composite treatment agent: adding a fermentat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com