Sealant modulation tempering tool for airplane front and back wet area floor beam structural construction

A technology of sealant and floor beam, applied in mixers, shaker/oscillation/vibration mixers, dissolving and other directions, can solve the problems of uneven modulation and low work efficiency, and achieve the effect of evenly quenching and tempering the sealant and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

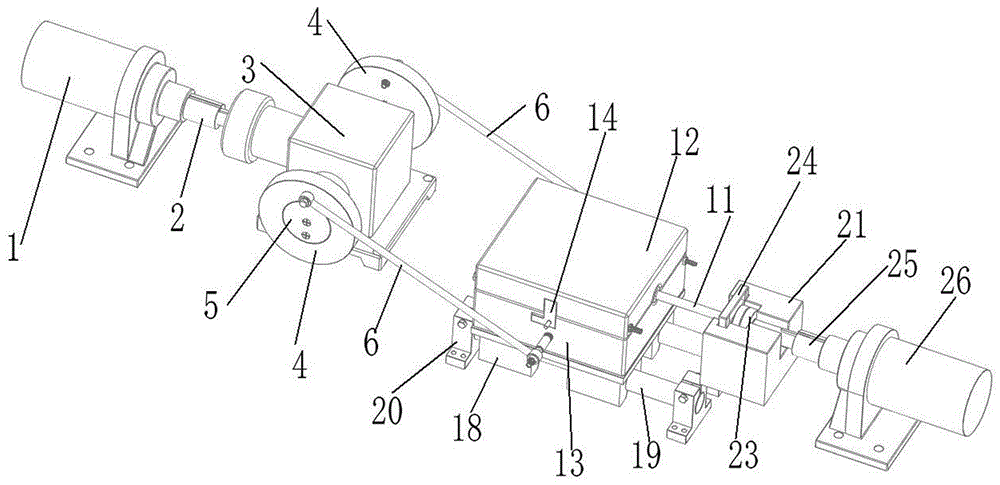

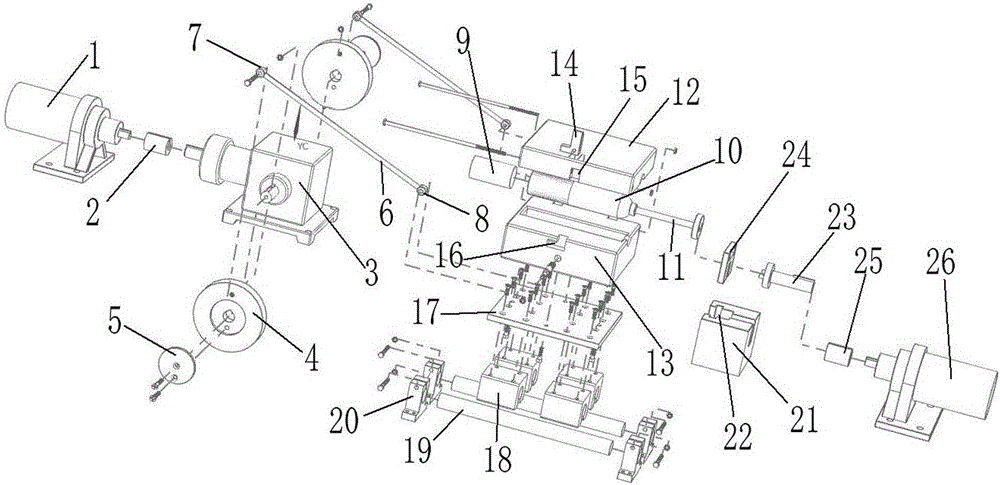

[0023] Attached below figure 1 , attached figure 2 The present invention will be further described.

[0024] A sealant preparation tool for the construction of the floor beam structure in the front and rear wet areas of the aircraft, comprising: a sealant cylinder fixing device for clamping and fixing the sealant cylinder 10; an optical axis 19, the two ends of which are horizontally fixed by fixing seats 20; The bearing 18 is slidably installed on the optical axis 19, the sealant cylinder fixing device is connected with the linear bearing 18; the fixing device 21 is provided with a groove 22 inside, and the sealant cylinder driving handle 11 of the sealant cylinder 10 is embedded and fixed in the groove 22: the rotary power device is connected with the sealant cylinder driving handle 11, and is used to drive the sealant cylinder driving handle 11 to rotate; and the horizontal motion driving device is connected with the sealant cylinder fixing device, and is used to drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com