Flue gas conditioning and atomization acid/alkali comprehensive reaction tower

A reaction tower, acid-base technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of expensive processing equipment, unacceptable technical work, low cultural quality, etc., achieve less energy consumption of materials, Easy maintenance and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

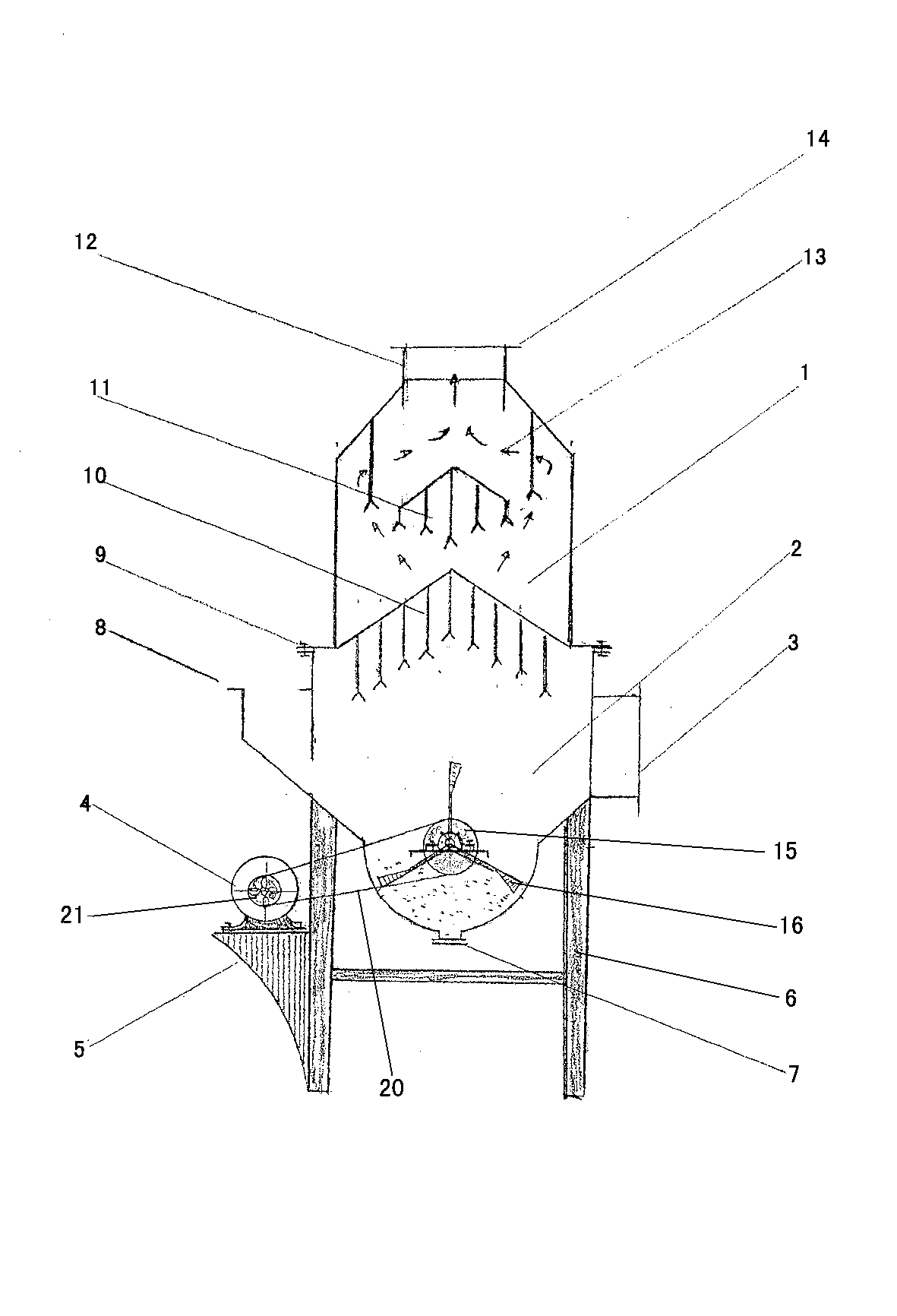

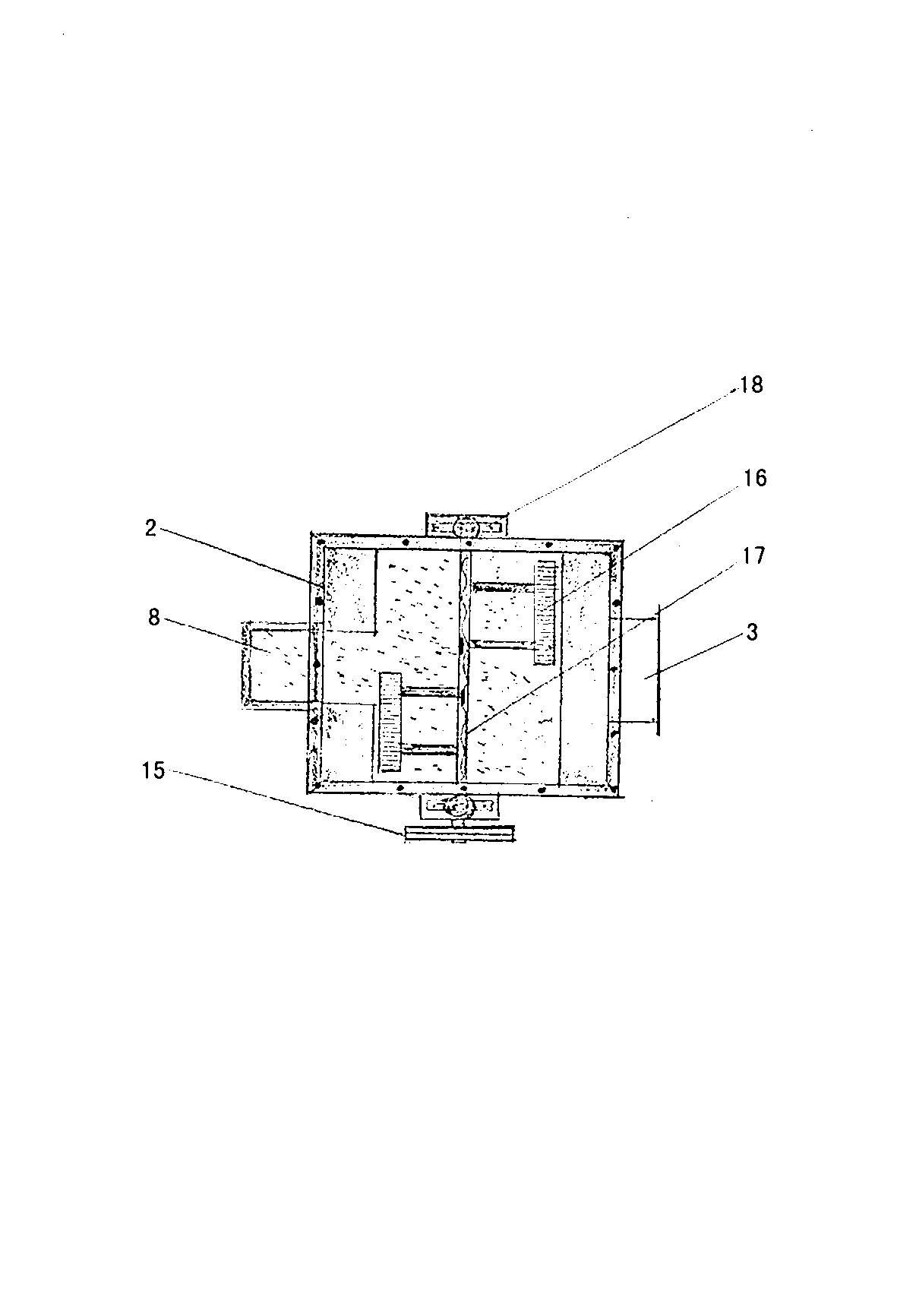

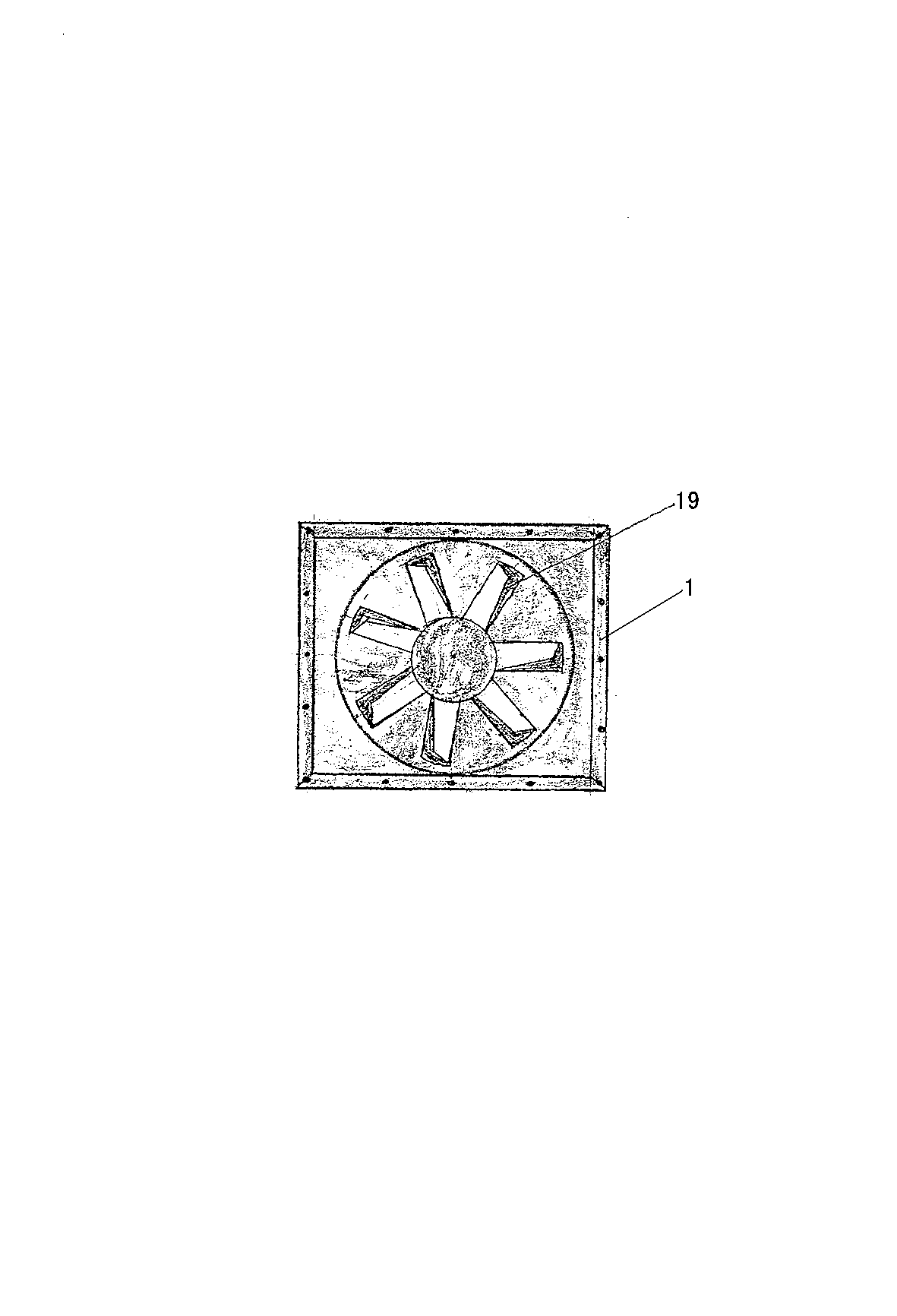

[0019] Such as figure 1 , figure 2 , image 3 As shown, the present invention is mainly composed of upper, middle and lower parts. The upper part (1) and the middle part (2) are connected by a flange (9), and the lower part is a support foot ( 6). Said upper part (1) is a circular cylinder, the top of the cylinder is a truncated cone, the center of the truncated cone is provided with a smoke outlet pipe (12), and the smoke outlet pipe (12) is provided with a The flange (14) is used to connect the smoke delivery pipe. The lower part of the smoke outlet pipe (12) extends to the middle of the cylinder body. The bottom surface of the smoke outlet pipe (12) is a herringbone back cover structure. There are three straight smoke outlets (13), the herringbone bottom surface of the smoke outlet pipe (12) and the outer space of the smoke outlet pipe (12), and a circle of blocking hooks made of flat steel is welded on the truncated conical inner wall ( 11), the lower end of the bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com