Conditioning method capable of reducing microorganism content in wheat

A microbial content, conditioning technology, applied in grain processing, grain milling, application, etc., to save construction costs, reduce conditioning time, and improve conditioning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

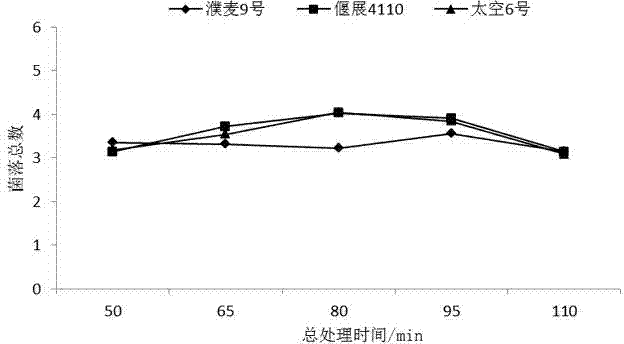

[0028] Example 1

[0029] This embodiment includes the following steps:

[0030] (1) Raw material selection: common wheat;

[0031] (2) Cleanup: clean up the wheat to remove impurities, dust and floating soil on the surface of wheat grains;

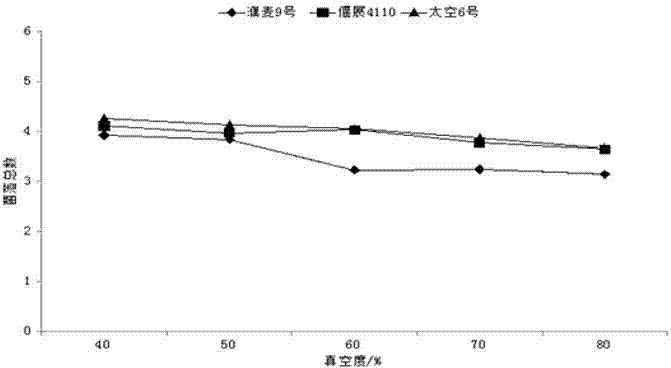

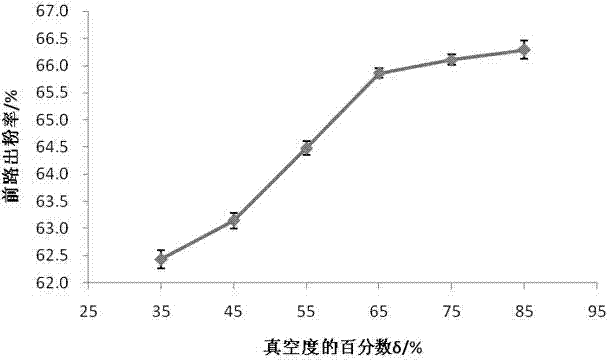

[0032] (3) Tempering wheat: In the wheat tempering stage, the water impregnator adds tap water to mix the wheat, and after mixing, enter the vacuum drying equipment with a vacuum of 65%, soak for 20 minutes, and then slowly soak for 30 minutes under normal pressure, and then prepare for grinding powder.

[0033] (4) Flour milling: use a mill to grind the tempered wheat, and collect the powder of each system.

[0034] (5) Collect finished products: mix, inspect and pack the powder of each system.

[0035]

Example Embodiment

[0036] Example 2

[0037] In this embodiment, the selection of raw materials, cleaning, powdering, and collection of finished products are the same as those in Embodiment 1, except that the subsequent processing methods are as follows:

[0038] Tempering wheat: In the wheat tempering stage, add tap water to the impregnator to mix the wheat. After mixing evenly, enter the vacuum drying equipment with a vacuum of 70%. After soaking for 18 minutes, after slowing down under normal pressure for 45 minutes, it is ready to be milled. .

[0039]

Example Embodiment

[0040] Example 3

[0041] In this embodiment, the selection of raw materials, cleaning, powdering, and collection of finished products are the same as those in Embodiment 1, except that the subsequent processing methods are as follows:

[0042] Tempering wheat: In the wheat tempering stage, add tap water to the impregnator to mix the wheat. After mixing evenly, enter the vacuum drying equipment with a vacuum degree of 75%. After soaking for 20 minutes, after 50 minutes under normal pressure, it is ready to be milled. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com