Novel multilayer mineral wool processing and preparing method

A new type of mineral wool technology, applied in the field of multi-layer processing and preparation of new mineral wool, can solve the problems of increasing energy consumption and production cost, polluting the environment, poor hand feeling, etc. Effect of improving dust and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

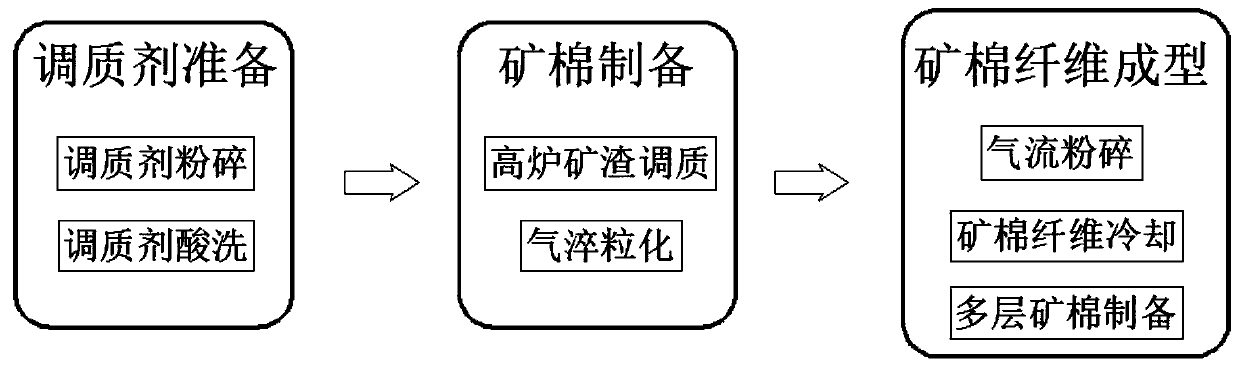

[0041] see figure 1 , a novel mineral wool multi-layer processing preparation method, its main preparation process is:

[0042] S1. Grinding of conditioner, pulverize the coal ore powder and iron tailings waste rock used as the conditioning agent, and mix the coal ore powder and iron tailings waste rock powder according to the ratio of 3:2 by mass, wherein the coal ore powder and iron tailings The ore waste rock only needs to be crushed simply, and the coal mine powder and iron tailing waste rock can be crushed into small pieces with a particle size of 30CM, which is convenient for later pickling and dissolution. At the same time, the small pieces with a particle size of 30CM can be completed by ordinary crushers. , reduce the crushing cost and reduce the cost of mineral wool preparation;

[0043] S2, conditioner pickling, the mixed conditioner powder is poured into dilute hydrochloric acid for pickling, and a small amount of insoluble matter is filtered to obtain a condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com