Garden waste biomass charcoal-based soil conditioning equipment and conditioning method thereof

A technology of garden waste and biochar, which is applied in the field of garden waste biochar-based soil conditioning equipment and its conditioning, can solve the problem of balanced input of biochar into soil, and the speed and effect of biochar conditioning soil are not ideal , Difficult to mix biochar with soil, etc., to achieve the effect of accelerating the reaction rate, improving efficiency, and increasing the degree of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

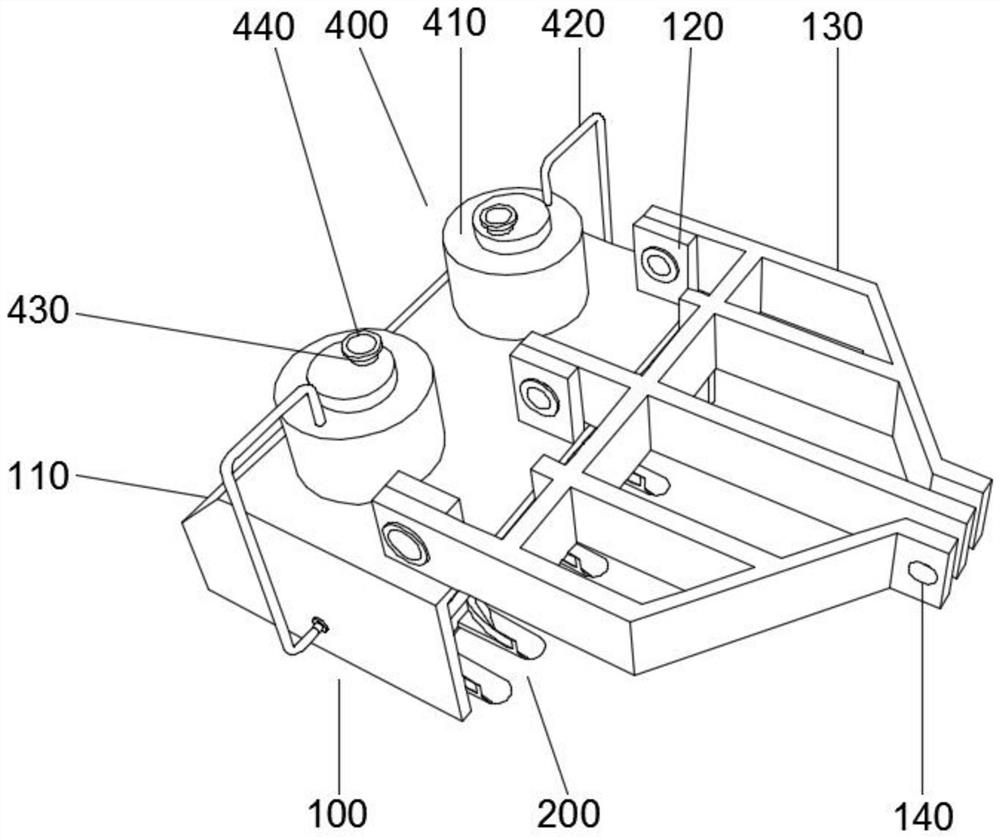

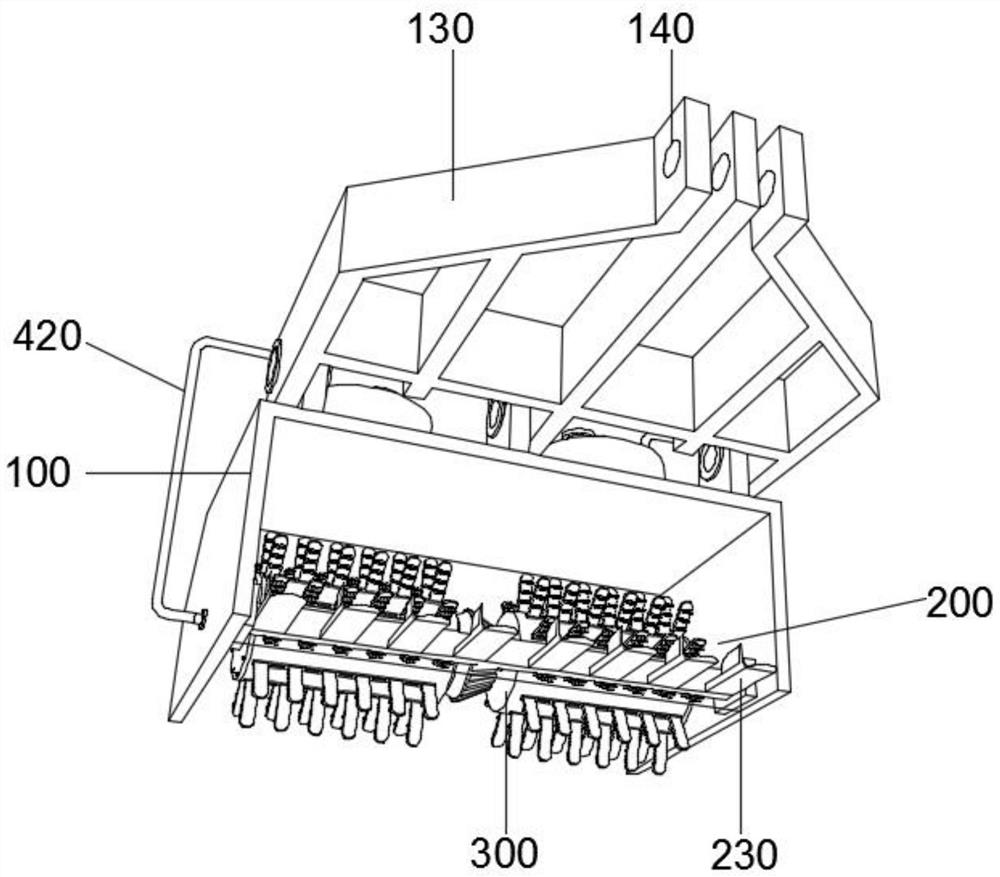

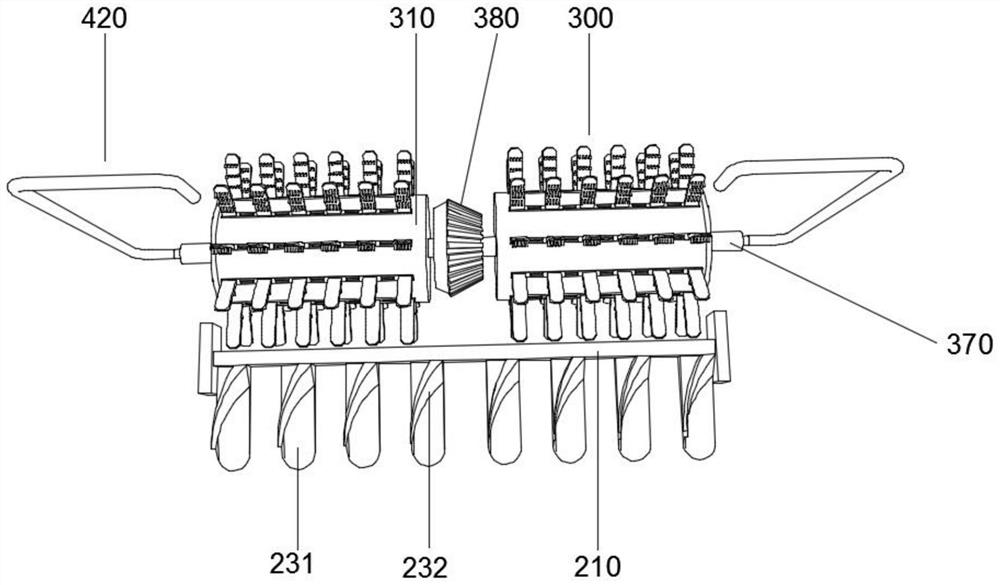

[0037] Refer to the attached Figure 1-11, the present invention provides a garden waste biomass charcoal-based soil conditioning equipment, in order to achieve the above purpose, the present invention provides the following technical solutions: a garden waste biomass charcoal-based soil conditioning equipment, comprising a shell 100, a shell The ground turning assembly 200 is fixedly installed on the inner wall of the front end of the 100, and the soil turning rollers 300 are rotatably connected between the inner walls of the left and right sides of the casing 100. The soil turning rollers 300 are symmetrically arranged in two groups. The biomass char distribution assembly 400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com