Feeding device for U-shaped pre-stress concrete pile plank and control method

A technology of concrete slabs and feeding devices, applied in electrical program control, program control in sequence/logic controllers, manufacturing tools, etc., can solve problems such as insecure quality, failure to meet process requirements, and material blocking at the feeding port , to achieve the effect of improving accuracy and uniformity, saving manpower consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

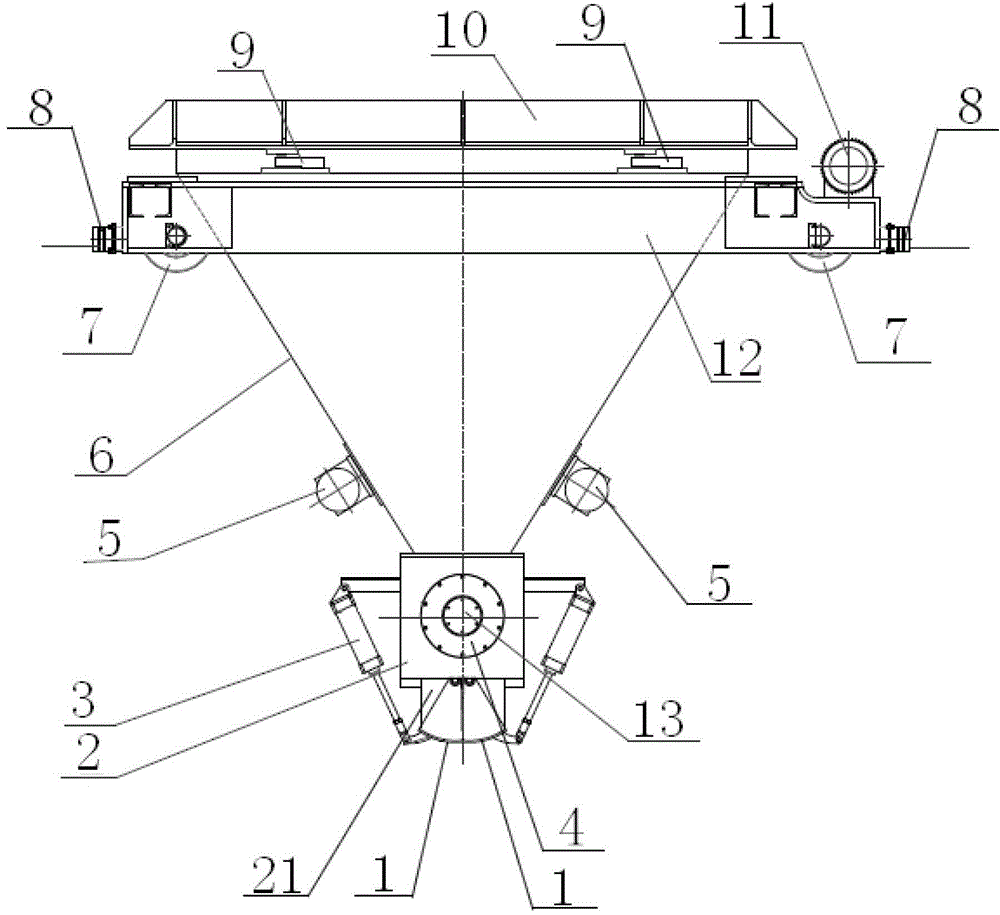

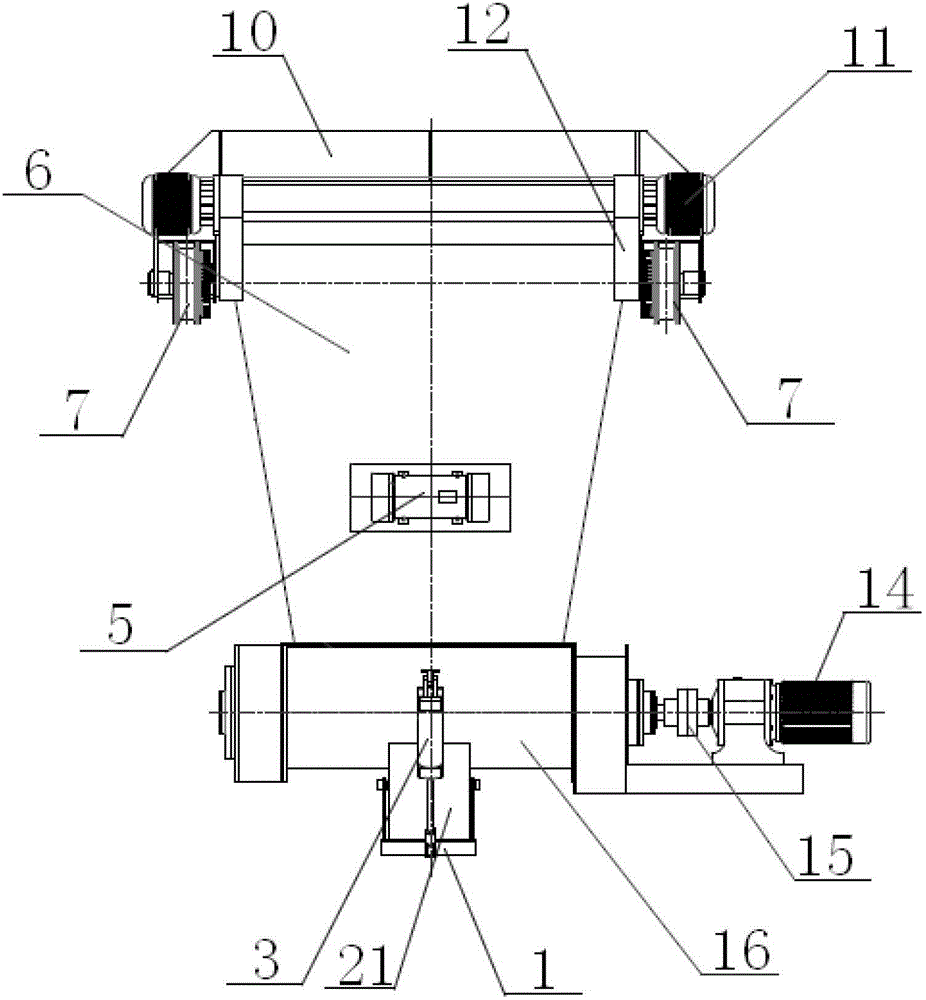

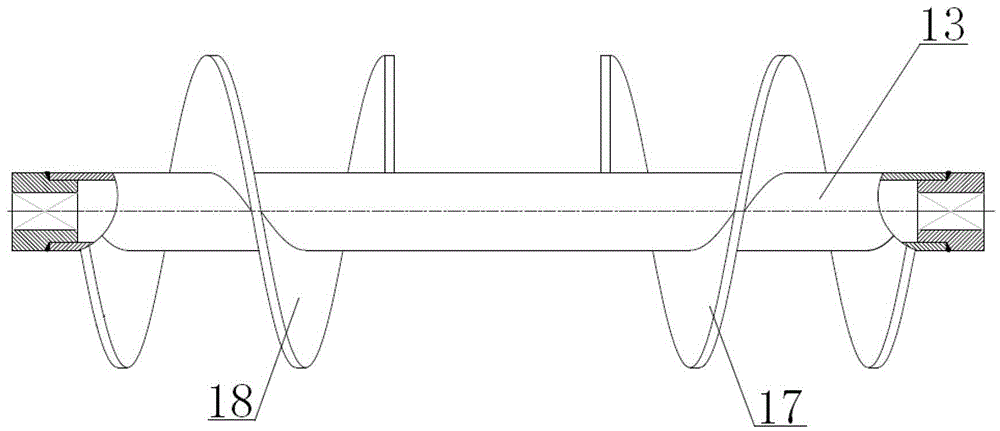

[0040] The feeding device for U-shaped prestressed concrete sheet piles provided by the present invention includes a hopper 6 and a cart traveling mechanism, such as figure 1 , figure 2 As shown, the hopper 6 is installed on a support stand 12 through the top fixing plate 10, and a plurality of load cells 9 (in this embodiment, four load cells are used) are installed on the support stand 12, Four groups of traveling wheels 7 are installed at the bottom of the supporting stand 12, and the traveling wheels 7 are driven by a motor 11 installed on the supporting stand 12, and the supporting stand 12 can follow the track of the cart traveling mechanism under the drive of the traveling wheels. Horizontal running for cross-line fabric;

[0041] The discharge port 21 of the hopper 6 is provided with at least one radian discharge gate 1, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com