Method for producing pellet feed for sheep from peanut straw

A technology of pellet feed and peanut straw, applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve problems such as low efficiency, and achieve the effects of improving digestive environment, fresh taste and high benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

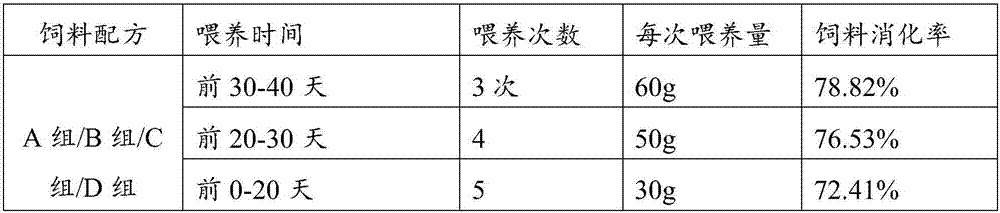

Image

Examples

Embodiment 1

[0030] According to one aspect of the present invention, this embodiment provides a kind of method that utilizes peanut stalks to produce sheep pellet feed, and described sheep pellet feed is made up of the raw material of following parts by weight: 53% of peanut straw, 5% of pine needle powder, 8% of soybean meal powder %, corn flour 7%, giant fungus grass 8%, carrot 8%, yeast powder 4%, sucrose molasses 3%, compound premix 5%, monensin sodium 0.3%, bacitracin zinc 0.2%, salt 2.0 %, the balance is distiller's grain powder; the sugar content of the sucrose molasses is 50%, and the superior grade sucrose molasses containing 0.5 million beneficial microorganisms / g; the content of monensin in the monensin sodium is 92.00% %, the bacitracin zinc is 10% or 15% bacitracin zinc powder, wherein the content of zinc is 3.00%.

[0031] The premix contains methionine, colistin sulfate, folic acid, tricalcium phosphate, vitamin premix, sodium selenite and potassium sulfate, and the methion...

Embodiment 2

[0039] According to one aspect of the present invention, this embodiment provides a kind of method that utilizes peanut stalks to produce sheep pellet feed, and described sheep pellet feed is made up of the raw material of following parts by weight: 65% of peanut straw, 2% of pine needle powder, 4.7% of soybean meal powder %, corn flour 4%, giant fungus grass 4%, carrot 5%, yeast powder 2%, sucrose molasses 1%, compound premix 2%, monensin sodium 0.2%, bacitracin zinc 0.1%, salt 1.0 %, the balance is distiller's grain powder; the sugar content of the sucrose molasses is 50%, and the superior sucrose molasses containing 10,000 beneficial microorganisms / g; the content of monensin in the monensin sodium is 95.00% %, the bacitracin zinc is 10% or 15% bacitracin zinc powder, wherein the zinc content is 7.00%.

[0040] The premix contains methionine, colistin sulfate, folic acid, tricalcium phosphate, vitamin premix, sodium selenite and potassium sulfate, and the methionine, colisti...

Embodiment 3

[0048] According to one aspect of the present invention, this embodiment provides a kind of method that utilizes peanut stalks to produce sheep pellet feed, and described sheep pellet feed is made up of the raw material of following parts by weight: 60% of peanut straw, 3% of pine needle powder, 6% of soybean meal powder %, corn flour 5%, giant fungus grass 6%, carrot 6%, yeast powder 3%, sucrose molasses 2%, compound premix 4%, monensin sodium 0.24%, bacitracin zinc 0.16%, salt 1.6 %, the balance is distiller's grain powder; the sugar content of the sucrose molasses is 48%, and it contains 08,000 beneficial microorganisms / g superior grade sucrose molasses; the content of monensin in the monensin sodium is 93.00% %, the bacitracin zinc is 10% or 15% bacitracin zinc powder, wherein the zinc content is 6.00%.

[0049] The premix contains methionine, colistin sulfate, folic acid, tricalcium phosphate, vitamin premix, sodium selenite and potassium sulfate, and the methionine, coli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com