On-line matter verifying device and method for belt feed weigher

A technology of calibration device and belt, applied in the direction of weighing equipment testing/calibration, etc., can solve problems such as inconvenient operation, and achieve the effect of improving calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

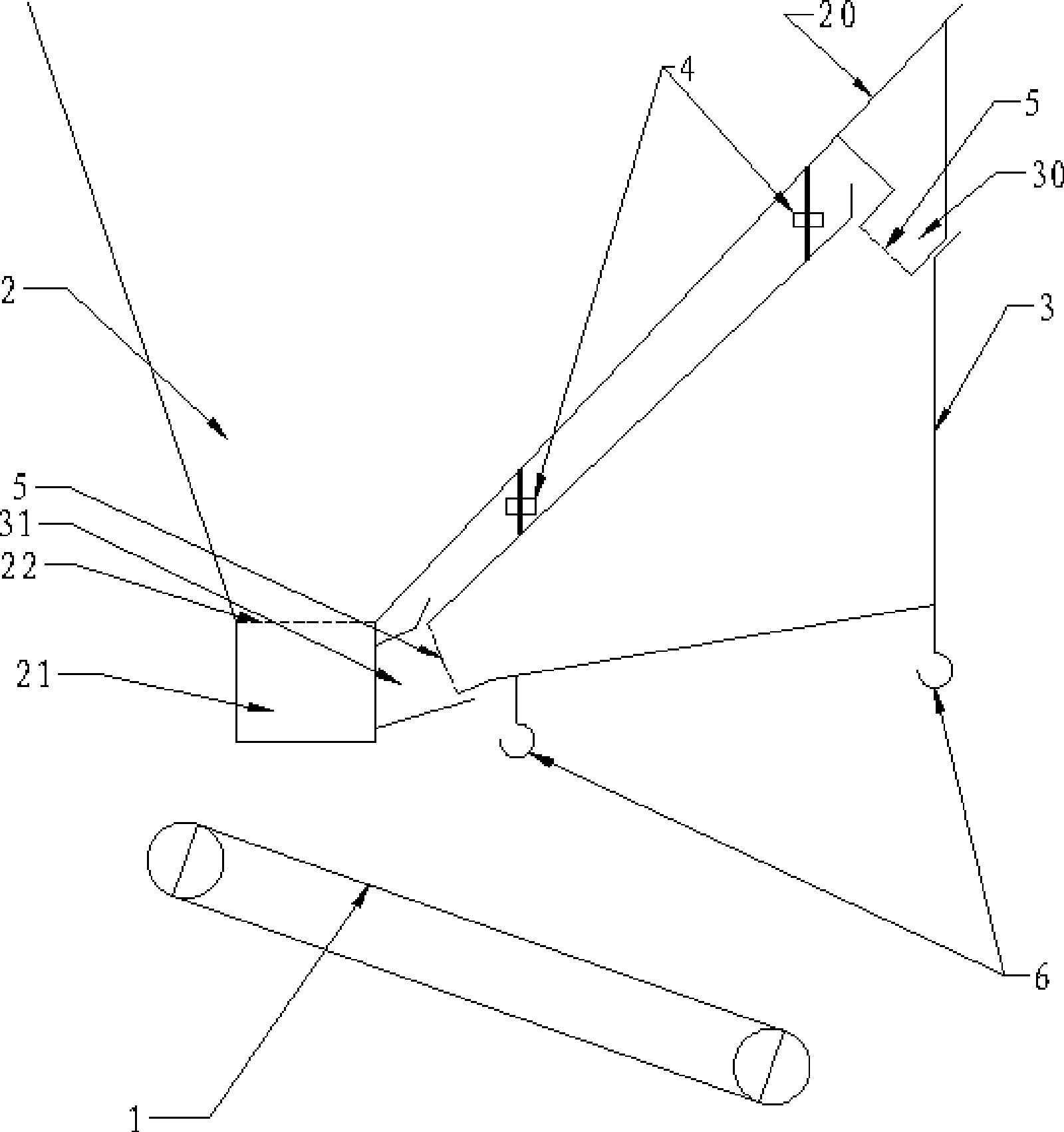

[0024] like figure 1 As shown, the material bin 2 is provided with a material bin discharge port 21 during normal production, and the material bin discharge port gate 22 can be used to close the material bin discharge port 21, and a hopper inlet is opened from the warehouse wall 20 of the material bin 2. The feed port 30 is installed with a manual flashboard 5, so that the physical object used for verification enters the hopper 3; a hopper discharge port 31 is provided on the warehouse wall 20 at the side of the material bin discharge port 21, and a manual flashboard is installed. 5. It is convenient to discharge material from the hopper 5 to the belt feeding scale 1; the hopper 3 is freely suspended on the material bin 2 through four load cells 4, so as not to affect the accuracy of weighing, and there are weights at the four corners of the bottom of the hopper 3 Hook 6.

[0025] In order to ensure the accuracy of the weighing when calibrating the hopper 3, when doing the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com